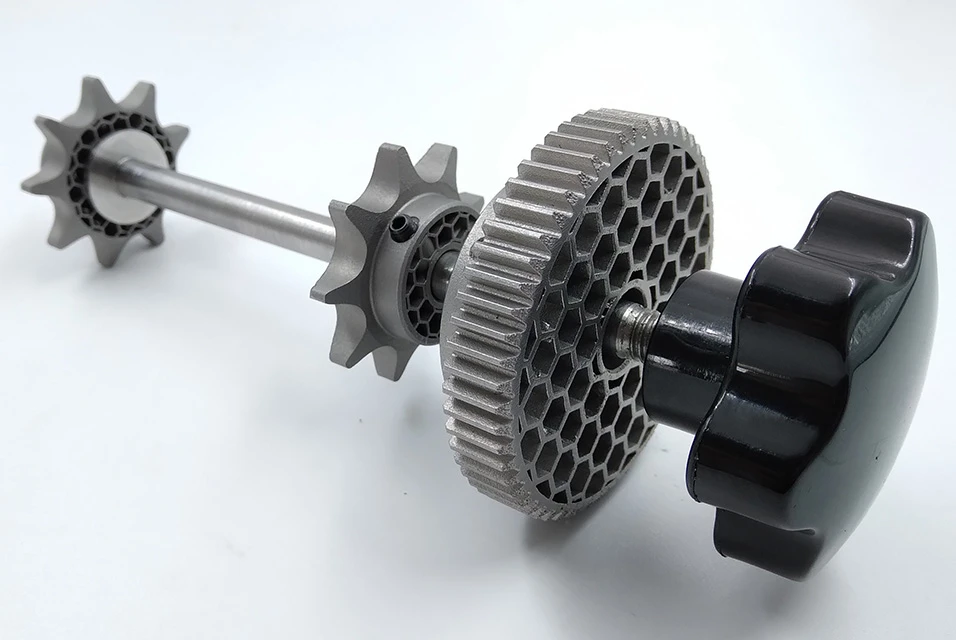

Mario Franchi, an Application Engineer for Additive Manufacturing at il Sentiero International Campus, faced the challenge of creating a lightweight gear and sprocket that could withstand high temperatures. To tackle this problem, he turned to Materialise Magics, design for additive manufacturing (DfAM), and a honeycomb structure.

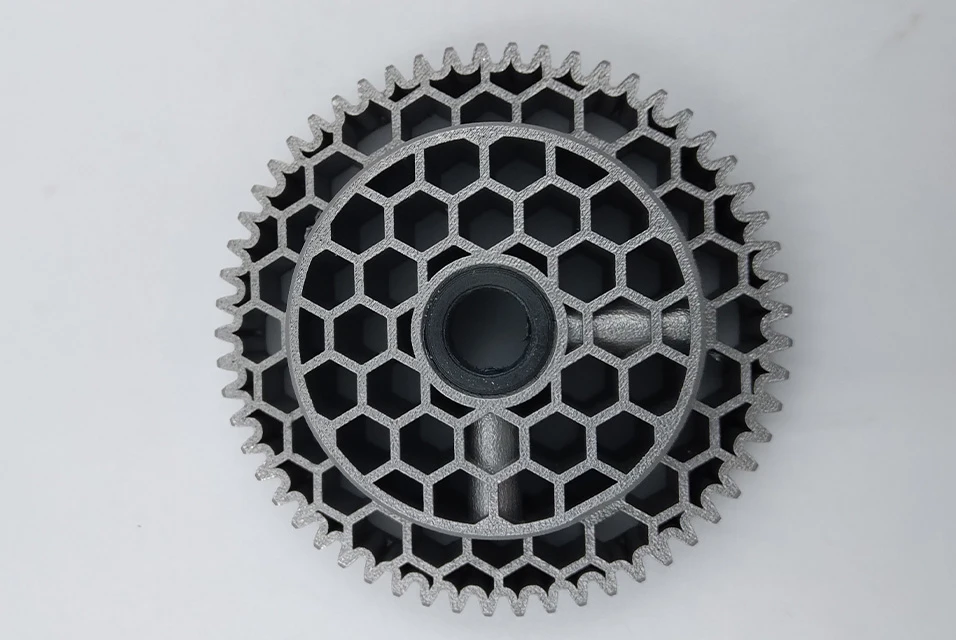

With the Magics software, Mario was able to quickly analyze and edit part orientation and support structures of a model within minutes without affecting the design’s build prep or printability. The use of the honeycomb structure provided significant weight reduction while ensuring printability and structure stiffness. He opted to print in Stainless Steel (AISI 316L), which is a durable and heat resistant material.

Unlike traditional CAD software, Magics is more intuitive, flexible, and practical, enabling the creation of geometries unachievable by standard manufacturing processes.

“I’m usually required to update a part and follow a set blueprint,” said Franchi.

“But for this project, I had the flexibility and freedom to develop something unique. The only criteria were that the 3D printed parts should be lightweight and able to withstand high temperatures,”

Lightweighting

By combining DfAM, Magics, and metal 3D printing, the engineer was able to produce a redesigned 3D printed gear and sprocket that were both lightweight and durable. Due to the honeycomb design and open structure, the remodeled gear was 61% lighter and the sprocket 53% lighter than their traditional counterparts.

The redesigned components have now been fitted onto ten shafts, and each shaft is 46% lighter compared to the standard models. Magics and metal 3D printing allowed Mario to break the mold and redesign parts, making them reliable and easy to print.

“I wanted to keep my design and 3D printed part as simple as possible,” said Franchi.

“It only took me a few minutes to identify that the honeycomb structure in Magics was perfect because of its strength (in terms of wall thickness) and its simplicity. Plus, you can easily construct and modify your designs in the software — it literally took seconds and a few clicks of a button — and printability wouldn’t be an issue.”

The success of this project highlights the potential for 3D printing to improve traditional manufacturing methods and create lightweight, durable, and efficient parts across industries.

Design Freedom

“Magics empowers users to express themselves like no other software, and AM enables geometries that are unachievable by standard manufacturing processes like injection molding,” said Jeremy Levecq, Sales Application Engineer at Materialise.

We concur. It’s also pretty handy for tidying up broken STL models!

To learn more about how Magics can help with your 3D printing workflow, head on over to this link.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.