Researchers in Japan are taking a common-sense approach to integrating 3D printing into their construction industry. Most companies that focus on 3D printed civil engineering structures do one of two things: they either build a giant 3D printer in a warehouse that fabricates parts that have to be shipped and assembled on-site or they develop a mobile 3D printer that can print the structures in place. The engineering team at Gifu University decided to design some upgrades that allow existing ICT construction equipment to be used for concrete 3D printing.

ICT stands for Information and Communications Technology in the construction world. It’s a catch-all term that refers to the use of software, sensors, and communication systems to plan, execute, and track construction projects. When construction workers on the job site can look at a tablet and see a CAD rendering of the designs created by the architect, and then plug that data into an excavator so that it can dig to exactly the right depth, that’s ICT.

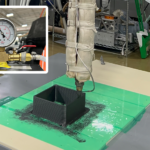

In this case, the researchers converted an ICT bucket excavator into a cement 3D printer by attaching a spray nozzle to the end of the bucket and employing its “infinite plane limit” function.

Besides researchers from Gifu University, the R&D group included the Research Institute for Construction Technology, Sumitomo Osaka Cement, Shimizu Construction, NIPPO, Maruei Concrete Industry, and FTS, so there was no shortage of cement expertise. As such, their 3D printing system is capable of printing in two different formats: wet and dry. In the wet mode, the mixture of cement is premixed before being loaded into the printer, whereas in the dry mode, the ingredients are fed separately and become mixed in the print nozzle as the cement is deposited. Both methods have advantages. Premixing generally results in a more thoroughly mixed cement but transporting premixed cement is more difficult and costly. So this printer provides the best of both worlds.

By combining the print nozzle, the infinite plane function of ICT excavator, and some expert excavator driving, the team was able to produce a 1.5-meter-tall pillar and a 1-meter-tall wall. The plan is that the technology will first be used in buried formwork at sites where it’s difficult to transport cement, but eventually they expect these types of printers will be used to print bridges superstructures.