Directed Energy Deposition (also known as Blown Powder Directed Energy Deposition) is not only good for manufacturing new parts from scratch, but it is also great for Additive Repair.

Additive Repair can be used for repairing broken metal components which may be too expensive to fabricate from scratch, so it’s more economical to simply repair it.

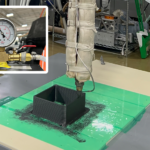

The broken part is loaded into the machine and the nozzle directs the blown powder through its laser, depositing the melt pool onto the broken part and restoring the geometry. It’s much like welding new geometry onto a part, layerwise.

Optomec have released a new production grade printer named the HC-TBR, which has some sweet new features including automated transfer of parts in/out of the inert gas filled chamber, and a vision system that scans the defective part and designs its own repairing toolpath.

The HC-TBR was officially launched at Formnext Connect along with a research level machine designated as the CS250.

The vision system is driven by Optomec’s proprietary AutoCLAD software which images the part and then automatically adapts and modifies the toolpath and printer parameters for each individual part based on variations in orientation, dimension, and shape. The software can respond dynamically and change the laser spot size (and the meltpool) therefore producing a smaller overbuild and reducing the amount of machining needed afterwards.

The AutoCLAD software was initially designed by Huffman, which has since been absorbed into the Optomec company.

AutoCLAD has been used extensively for the repair of high value parts particularly in the aerospace sector. Turbine blades seem to be a popular item for repair which is understandable given how they are manufactured (many blades are actually “grown” from a single metal seed, producing a monocrystal structure before being sent for machining). It’s not a cheap process.

For example the cost of a LPC blade from a Rolls-Royce Trent XWB engine costs as much as a Ferrari F430, so naturally a repair strategy is preferred for similar items.

You can see Optomec LENS in action below, doing its repair magic on a turbine blade.

Previously the AutoCLAD system was available as an optional extra (and it still is) to be retrofitted on Optomec LENS systems that use the Siemens 840D controller, but now with the HC-TBR machine it is available as standard.

The industrial grade HC-TBR features a build area of 250 x 250 x 250 mm and will set you back around 400k USD. If you are curious about the ROI that investment will get you (especially on turbine blades) you can read the Optomec whitepaper.