Oak Ridge National Laboratory has successfully demonstrated the printing of an alloy consisting of titanium and molybdenum, the unpronounceable 42nd element on the periodic table.

So what is this wondrous metal and what are its applications?

Molybdenum

First up, it’s pronounced Muh-lib-dunham, or simply “Mo” for short.

Molybdenum itself is valued for its ability to withstand high temperatures without expanding or losing its strength too much. It also has high corrosion resistance and weldability. For these reasons, it is used in metallurgy for the enhancement of alloy metals. Applications includes glass-to-metal seals, lighting, furnace shields, and semiconductors.

Most of the molybdenum used in alloys on Earth end up in various steel alloys such as structural steel or stainless steel, with a small amount ending up in various superalloys.

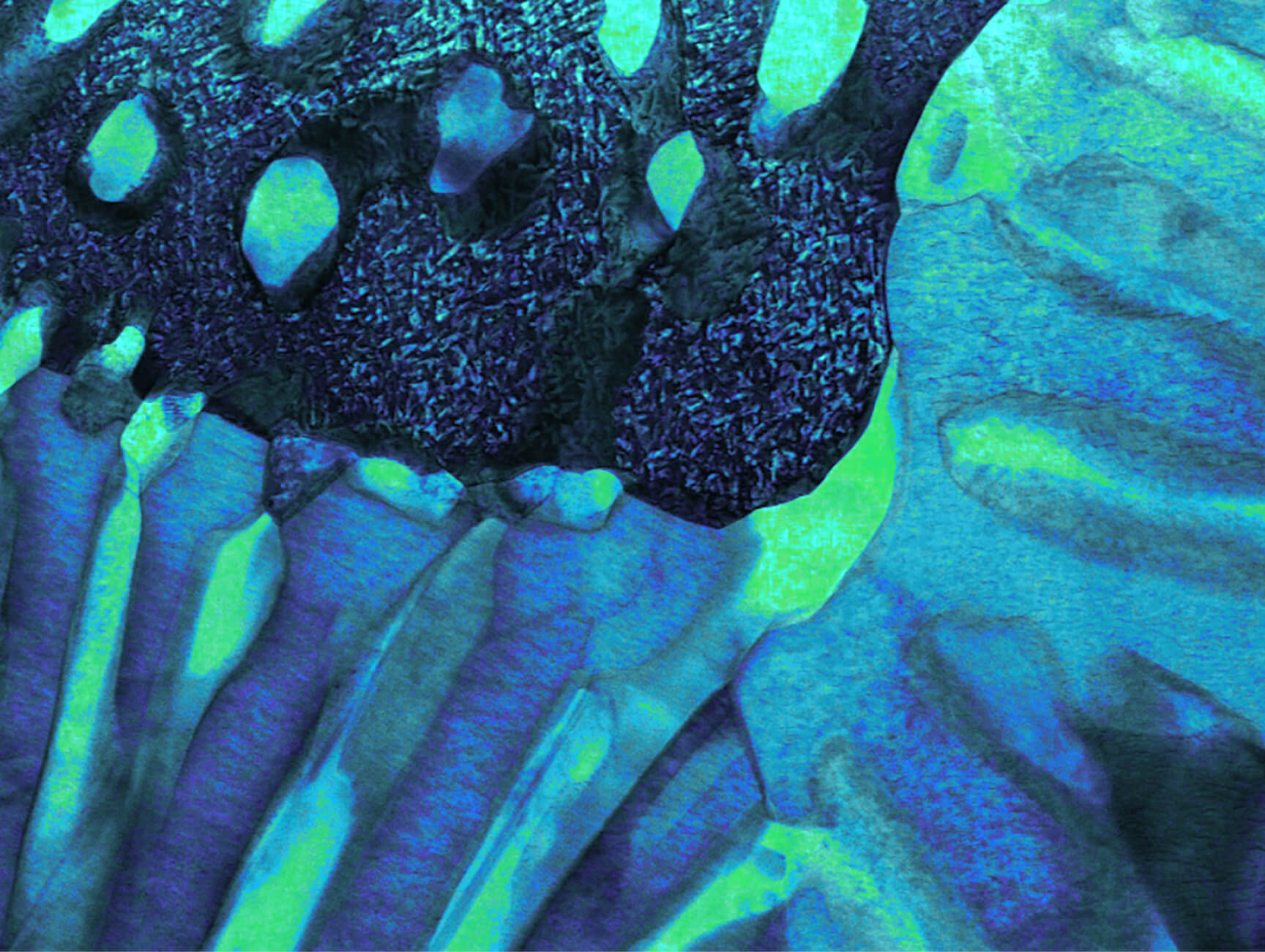

Because it is a reactive, brittle metal with a high melting point, molybdenum is difficult to manufacture via traditional methods. The reactivity also makes molybdenum difficult to print with normally, as contaminants can result in grain defects in the printed part, ultimately resulting in crack propagation.

However, the team of researchers have demonstrated that by manufacturing the powders in an argon environment they are able to create powders with minimal oxidation.

Crack Free

The manufactured molybdenum and titanium carbide powders were then ground up in a ball mill to ensure a homogenous mix before being fused into the molybdenum titanium carbide alloy by use of an Arcam EBM system.

The resulting alloy powder mix consisting of the molybdenum and titanium carbide was deposited in sandwich-fashion, resulting in a molybdenum structure with the titanium carbide particles discretely scattered throughout. In addition, pure molybdenum samples were printed.

“Our results showed that fabrication from a mechanically alloyed metal matrix composite powder is feasible,” said Mike Kirka at ORNL.

“The structures formed by the fused powders can withstand high temperatures, indicating that molybdenum and its alloys can be used for aerospace and energy conversion applications.”

The research findings have been published in the Journal of Manufacturing, which you can access over at this link.