“War! What is it good for?” asked Edwin Starr. “Absolutely nothing!” was his oversimplified reply.

He was partly correct. As it turns out, war is pretty good for finding innovative new ways to blow stuff up.

That’s exactly what the US Marine Corp (USMC) has been doing lately in the domain of mine clearance, with their 3D printed metal rocket cap. What is a rocket cap exactly, and why is a 3D printed one better? Read on to know more.

Rocket Cap

The M58 Mine Clearing Line Charge is a rocket-projected explosive line charge used for demining activities. A line charge generally speaking is a long line with explosive charges attached along its length. It is fired from a vehicle by rocket, and the rocket pulls the line charge out to its full length across the minefield. Once laid out, the charges detonate and trigger any mines in the swath of the line charge, making way for troops and vehicles to safely cross.

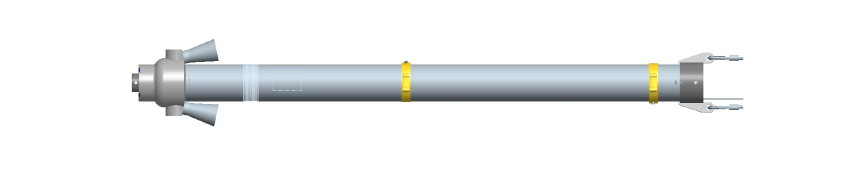

In the case of the M58 here, it can apparently blast a corridor measuring 100 metres by 8 metres. The 5-inch MK22 Mod 4 rocket carries the line which contains 5lbs (2.27kg) of C4 explosive per linear foot (0.3m) of line. And on the end of that rocket sits a cap. Traditionally it seems that these may be made from metal casting and machining.

The new version does away with all those processes in favour of the 3D printed one you can see in the picture below.

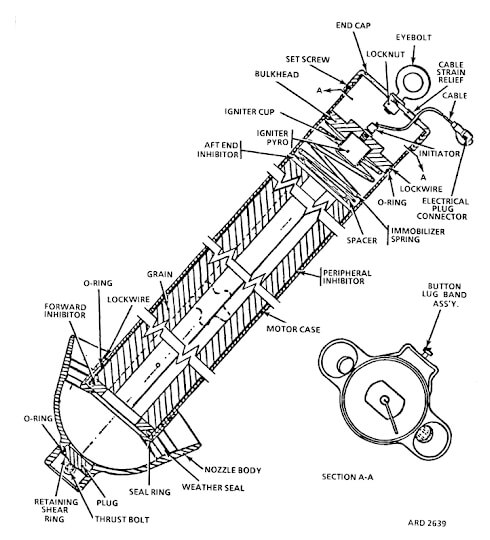

The drawing in the image below shows the cutaway of the MK22 Mod 4 rocket. The end cap sits on the end and is connected to the nozzles.

Note that unlike most rockets, the nozzles are on the nose of this rocket, and not the tail end (presumably for stability, and so it doesn’t set the line on fire).

There is a fair bit of complicated geometry inside the end cap as you can see.

The Program Manager for Ammunition at Marine Corps Systems Command (PM Ammo) has been experimenting with the use of additive manufacturing for these caps, as traditional methods of manufacture are costly and time consuming.

Successful Test

After much R&D, a test article was printed by the Naval Surface Warfare Center Corona Division and deployed at Yuma Proving Ground in Yuma, Arizona. By all accounts, the test was a success and the mines were cleared from the test area.

“The rocket motor fired off just as intended and the line charge detonated as it is supposed to, which was a significant moment for us.” CWO2 Justin Trejo, Project officer with PM Ammo at MCSC.

We don’t have a video of that exact test at Yuma, but there is a great video below showing the deployment of the rocket and subsequent detonation of the line thereafter.

“We’re able to create equipment parts and other assets for whatever particular mission we’re engaged in,” said Trejo.

“This 3D-printed headcap represents the Marine Corps going above and beyond to support our Marines.”