A team of researchers from Penn State University have recently published a paper in the Advanced Functional Materials and Biofabrication journals, detailing their research into 3D printed breast cancer tumors.

The research aims to allow the development of higher fidelity tumor models which can aid in more effective CAR-T cell therapies, while reducing dependence on in-vivo (animal-based) methods. It will increase understanding of how human immune cells interact with solid tumors.

Vascular

Breast cancer is the second leading cause of cancer death in women and accounting for a staggering 10 million deaths in 2020 alone. While deaths from breast cancer have been falling steadily since 1989, research into therapeutics has been hampered by a lack of physiologically-relevant pre-clinical diagnostic platforms.

There have been systems developed utilizing multicellular spheroids and microfluidic devices, they typically involve fairly lengthy fabrication processes with limited control on localization of tumors.

Because tumors are dynamic and unique, this approach requires that the initial master mold design be altered according to the changes in position with respect to primary vasculature.

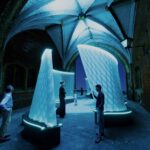

The location of vasculature (blood vessels) in relation to the tumor is important, playing a predominant role in tumor growth, as it controls diffusion of oxygen and nutrients, which is critical to the tumor’s survival.

The new research allows the rapid development of models that can better replicate the position of the vascular system with respect to the bioprinted tumor spheroids.

Research

The researchers utilized aspiration-assisted bioprinting to precisely locate tumors in three dimensions and create the tissue for testing.

The team first tested the accuracy of the model by treating it with doxorubicin, a commonly used chemotherapeutic drug for treating breast cancer. After confirming that the bioprinted tumor responded to the traditional chemotherapy, the team progressed on to testing a CAR-T cell-based immunotherapeutic treatment on the printed tumor.

A CAR-T cell (Chimeric antigen receptor T-cell) is a T-cell that has been genetically engineered to produce an artificial T-cell receptor for use in immunotherapy. They kill cancer cells, in other words. Immune-cancer interactions in the old microfluidic models have mostly been studied with monocytes (THP-1) as model immune cells, which fail to capture the cross talk of the CAR-T cells and the unique tumor microenvironment.

With the printed analogue, the researchers used human CAR-T cells that were engineered via gene editing to recognize and fight an aggressive form of breast cancer cells. After 72 hours of circulating the edited CAR-T cells through the vascular model and into the printed tumor, the researchers found that the cells within the tumor had generated a positive immune response and were fighting off the cancer cells. It was shown that the experiment resulted in approximately a 70% reduction in tumor volumes

Printing the Model

First, a device was designed with a chamber to contain the biologics with perforations on opposite walls, which would serve as connection ports for perfusion of therapeutics and other fluids. A stainless-steel wire was inserted through the wall perforations followed by hydrogel deposition to half-fill the device.

A combination of tdTomato+ human umbilical vein endothelial cells (HUVECs), green fluorescent protein positive (GFP+) MDA-MB-231, and human dermal fibroblasts (tumor spheroids), were determined to be representative of a native tumor microenvironment, as well as being mechanically suitable for bioprinting.

Employing aspiration-assisted bioprinting, the tumor spheroids were precisely bioprinted at pre-defined distances from the stainless-steel wire within the first 5 min of the deposition of a composite collagen/fibrinogen hydrogel to prevent irreversible damage to the hydrogel integrity.

After bioprinting, additional hydrogel was deposited to completely fill the device and incubated at 37 °C for 30 min. On complete cross-linking, the stainless-steel wire was gently removed from the device, creating an open channel to mimic the vasculature.

Next, HUVECs were introduced into the channel and the following day, the device was connected to an external pump to initiate media flow through the channel. The bioprinted tumor spheroids gradually developed sprouts, where the extent of sprouting was dependent on the distance of the tumor from the perfused vasculature. These vascularized devices were further evaluated for their efficacy in chemo and immunotherapy, and as mentioned previously, the results showed promise with tumor reduction being observed.

The graphic below explains the process.

“We’ve developed a tool that serves as a clinical test platform to safely and accurately evaluate experimental therapies,” said Ibrahim Ozbolat, professor of engineering science and mechanics, biomedical engineering and neurosurgery at Penn State and the senior author of the study.

“It is also a research platform for immunologists and biologists to understand how the tumor grows, how it interacts with human cells, and how it metastasizes and spreads in the body.”

You can find the full paper (open access) at Advanced Functional Materials journal, over at this link.