The nuclear industry is raising the quality-bar in terms of additive manufacturing again, this time by installing a 3D printed steel component in a Swedish nuclear power plant.

The component in question is an upper tie plate grid, which has been installed on top of an ATRIUM 11 fuel assembly at the Forsmark Nuclear Power Plant, which is operated by Vattenfall, in Sweden. It has been designed by Framatome, who are designers of nuclear equipment.

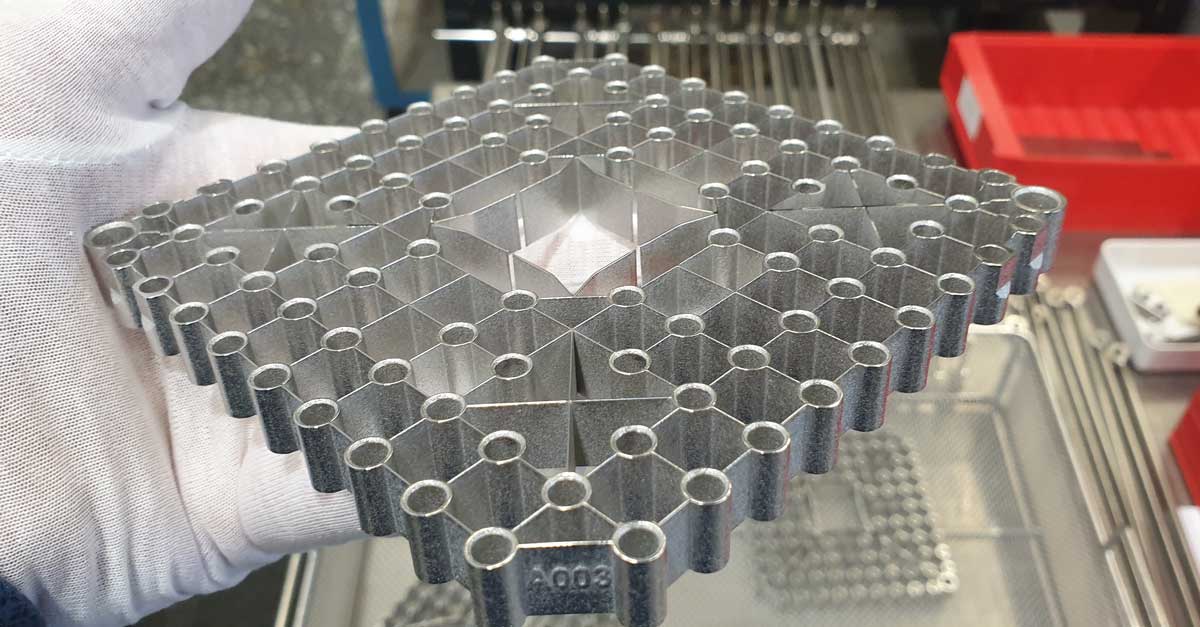

Let’s have a look at the printed component, and then take a look at this fuel assembly in some more detail. Here’s the printed upper tie plate grid.

It sits on top of the ATRIUM 11 fuel assembly, which is the most advanced boiling water reactor (BWR) fuel design on the market today. It has been operating in plants worldwide since 2012 as lead fuel assemblies (LFA).

Now, with its little 3D printed hat, it has maintained its innovative edge.

BWRs are common in the nuclear industry, and work by having the reactor core hea water, which then boils and turns to steam, which in turn drives a turbine, generating electricity.

Fuel assemblies are a grouping of metal-clad fuel rods that sit inside the core that produce the energy generated by nuclear reactors.The ATRIUM 11 fuel assembly is the only 11×11 grid available, and you can see what the old tie plate grid looks like in the image below.

The purpose of the grid is to hold the fuel rods in place and prevent debris from entering the system. Traditionally, they are fairly complicated to manufacture, as they are fashioned from stamped sheets that are laser welded together, requiring lots of monitoring and from production engineers.

With additive manufacturing, these steps are reduced, which reduces inventory and build time while increasing design options for engineers.

“The safe operation of fuel assemblies is key to Vattenfall,” said Ella Ekeroth, Manager of Fuel Components & Performance at Vattenfall.

“Along with this basic principle, our contributions to the development of efficient and reliable manufacturing processes are in the best interest of the entire nuclear industry. The overall goal of these activities is to maintain and further enhance safety and enable economically viable long term operations.”

This is not the first time that Framatome has dabbled with additive manufacturing for their nuclear reactor components. Since 2015 they have been researching and developing stainless steel and nickel-based alloy fuel assembly components, and in 2021 they collaborated with ORNL to produce and install a 3D printed channel fastener into an American BWR nuclear power plant.

“Advancements in the integrity of components manufactured using 3D-printing are revolutionary in the generation of safe, reliable low-carbon energy for long term operations,” said Lionel Gaiffe, senior executive vice president of the Fuel Business Unit at Framatome.

“We appreciate Vattenfall for opening its doors and providing a stepping stone for future innovations and developments that will replace conventional manufacturing.”