Oak Ridge National Laboratory (ORNL) researchers have demonstrated that 3D-printed metal molds offer significant advantages for producing large composite components for automotive manufacturing. The study, conducted at ORNL’s Manufacturing Demonstration Facility (MDF), found that large-scale additive manufacturing can create complex metal molds more efficiently than traditional tooling methods. This approach could help accelerate the adoption of lightweight composite materials in vehicle production.

“This kind of technology can help reindustrialize the U.S. and boost its competitiveness by creating smarter, faster ways to build essential tools,” said lead researcher Andrzej Nycz with ORNL’s Manufacturing Robotics and Controls group. “It brings us closer to an automated, intelligent production process.”

Traditional metal tooling involves subtracting material from large steel blocks, which can remove up to 98% of the original material and generate substantial waste. In contrast, additive manufacturing deposits metal layer by layer using widely available welding wire, reducing waste to approximately 10%. The process also enables the creation of more complex mold geometries, such as internal heating channels, that would be difficult to achieve with conventional machining.

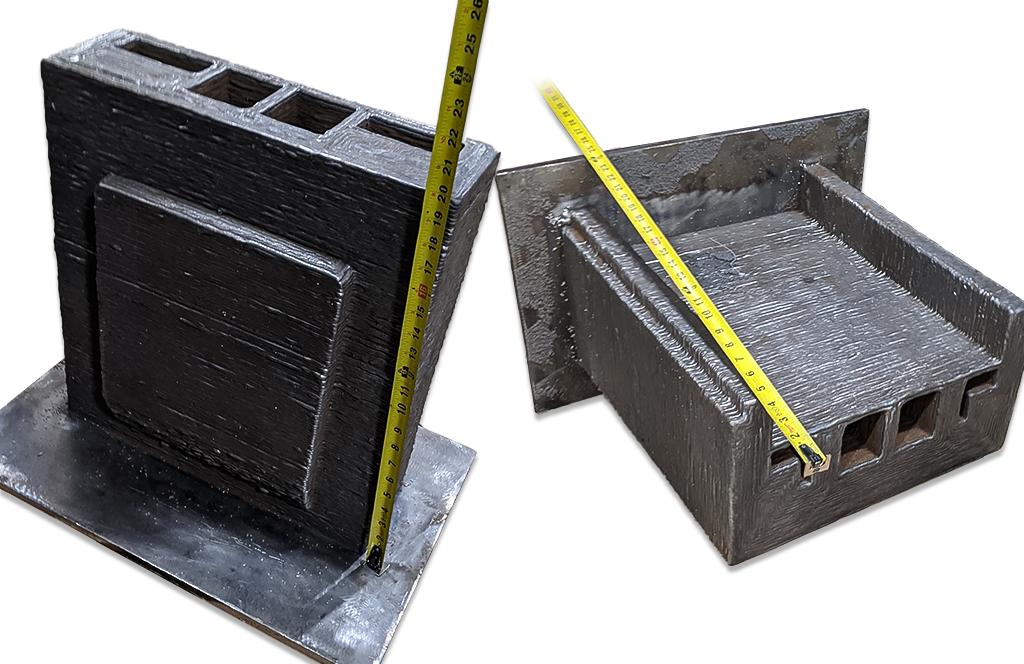

The research team partnered with Collaborative Composites Solutions (CCS) to test the concept by 3D printing a large battery enclosure mold with intricate internal features. Using gas metal arc welding (GMAW) additive manufacturing at Lincoln Electric Additive Solutions, they printed two near-net-shape dies from stainless steel ER410 wire. The team applied a specialized toolpath strategy to reduce weight while maintaining strength.

Analysis confirmed that the lightweighted mold met structural performance requirements, validating the feasibility of additive manufacturing for high-performance production tooling. The project was funded by the Department of Energy’s Advanced Materials and Manufacturing Technologies Office (AMMTO), with additional researchers from Composite Applications Group, ORNL, and Lincoln Electric Additive Solutions contributing to the work.

Source: ornl.gov