A 3D-printed concrete bridge called Diamanti has been unveiled at the Time, Space, Existence exhibition in Venice as part of a research collaboration led by the University of Pennsylvania. The 2.5-meter-long structure was designed by Professor Dr. Masoud Akbarzadeh and his team at the Polyhedral Structures Laboratory, with fabrication handled by Dutch company Vertico.

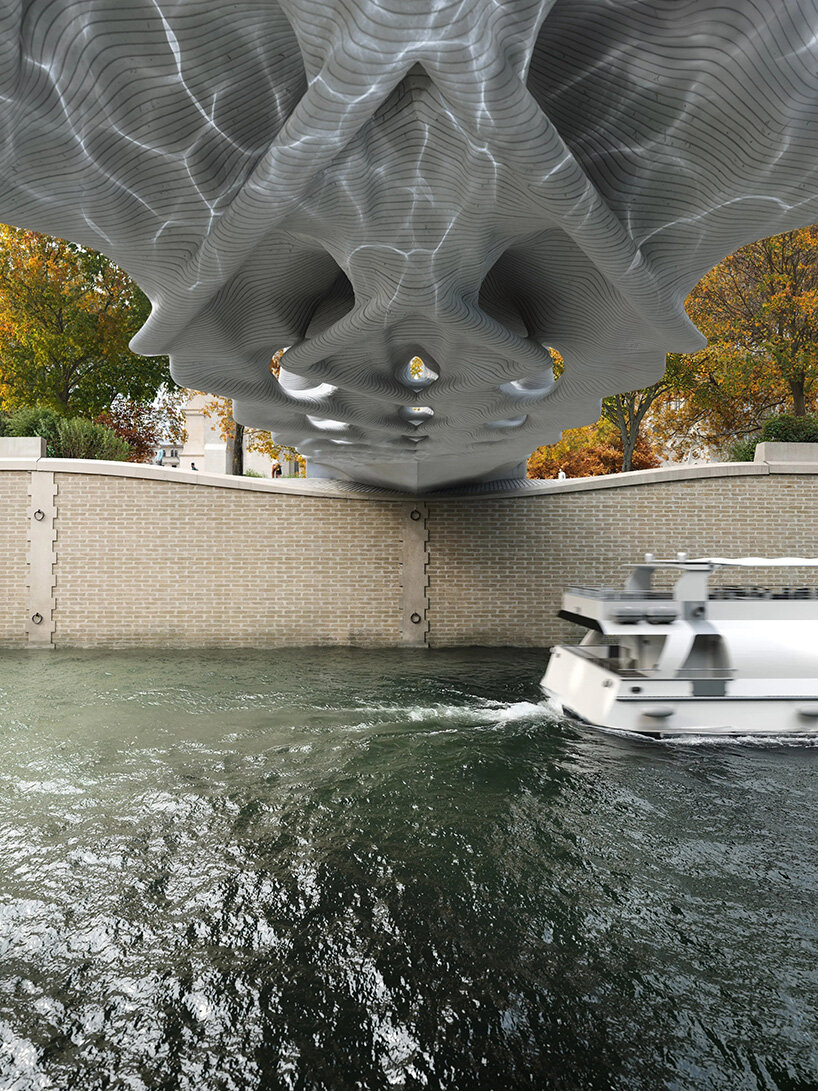

The bridge consists of nine prefabricated concrete segments, each 3D printed using a robotic arm and a two-component cementitious mix developed by Swiss company Sika. The segments feature internal voids and surface patterns designed to reduce material usage while maintaining structural performance. Eight steel cables hold the segments together through a post-tensioned system that requires no adhesives or grout, allowing the entire structure to be disassembled and recycled.

The design uses Polyhedral Graphic Statics (PGS) methodology to optimize force distribution through the structure’s geometry. Each segment incorporates anticlastic diamond surfaces that provide stiffness and load distribution while minimizing concrete usage. The Venice display model measures 2.5 meters in length with a depth of 26 centimeters, though the design has been tested successfully at a full 9-meter span.

The project involved multiple industry and academic partners across different phases of development. Sika Group created the specialized concrete mix for robotic printing, while Carsey 3D managed fabrication logistics and AEVIA provided post-tensioning expertise. Structural analysis was conducted by researchers at City College of New York and Villanova University, with physical load testing performed at the CERIB institute in France.

Source: designboom.com