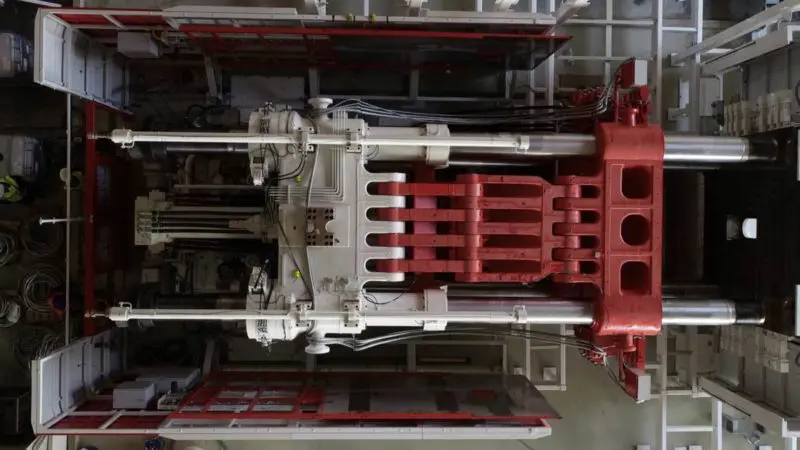

In a quiet but significant move, Tesla is poised to redefine the landscape of electric vehicle (EV) production. The company has employed a series of innovations, including the pioneering use of massive presses with up to 9,000 tons of clamping pressure in a process known as “gigacasting.” This approach has already significantly reduced production costs for Tesla’s Model Y.

However, Tesla is not stopping there. The company is on the cusp of yet another breakthrough, one that could allow them to die-cast the entire complex underbody of an EV in a single piece, as opposed to the hundreds of parts typically required in conventional cars.

Central to Tesla’s strategy is 3D printing and industrial sand, both of which have played pivotal roles in designing and testing molds for mass production. This approach has enabled Tesla to create hollow subframes with internal ribs, reducing weight and enhancing crashworthiness.

Traditionally, automakers have avoided casting such large structures due to the cost and risks associated with creating molds. Tesla’s approach involves using 3D printers that deposit a binding agent onto layers of sand to build molds for casting molten alloys. This method reduces costs significantly and accelerates the design validation cycle, taking only two to three months compared to the traditional six months to a year for metal mold

Tesla’s upcoming small EV, designed for personal use and robotaxi services, offers a perfect opportunity to cast an entire EV platform in one piece, given its simplified underbody structure. However, the choice of Gigapress technology remains a pivotal decision, with options ranging from high-pressure machines for productivity to slower alloy injection methods for quality and versatility.

These innovations are not only advancing Tesla’s production capabilities but also have the potential to reshape the entire automotive industry, making affordable and sustainable EVs more accessible to the masses.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.