The engineers team at Columbia University has managed to create a synthetic muscle that can operate without actuators, compressed air, or pressure regulators. While most robotics require lots of smaller parts and ancillary equipment to function, this one operates on its own.

The components of the hand itself are actually softer than any previous iteration of such a project. This allows it to have a delicate touch whilst being able to lift many 1000 times its own weight. The purpose of this is not only to produce strong robotics but to also allow for machines to conduct operations that require the handling of fragile materials such as medical equipment.

“This is a big piece of the puzzle and, like biology, the new actuator can be shaped and reshaped a thousand ways. We’ve overcome one of the final barriers to making life-like robots.” said Hod Lipson, lead researcher on the project.

3D Printed Robotics

We’ve previously reported on many stories about prosthetics and mimetic arms. This one is the most intricate version to date. One of the core ways that this is a breakthrough is the mix of strength and softness with minimal weight. Previous robotic limbs have always suffered from these problems in one way or another.

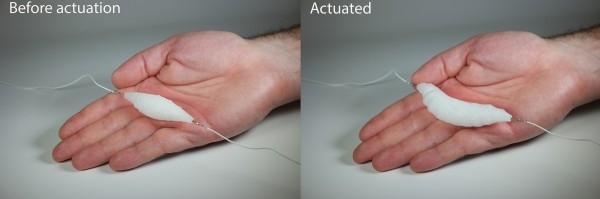

The robotic arm achieves this impressive design feature due to its materials and core components. It consists of a silicone rubber matrix containing microbubbles of ethanol that acts as a muscle. The muscle actuates when a resistive wire allows a low power charge to pass through it. This works in the same way as the contraction and expansion of the networks of tissue within the human body.

The entire process of creating a machine with such intricate parts could not be possible without 3D printing. Due to the advances in engineering technology, the researcher developed a super-strong robot that has 15 times more strain density than human muscle tissue. With advances in robotics on the hardware and AI front, it’s just a matter of time till engineers will be able to mix them together for a new wave of automated industrial technology.

Featured image retrieved from University of Houston.