Additive manufacturing and tensegrity and robots? Soft ones? These are three of our favorite things.

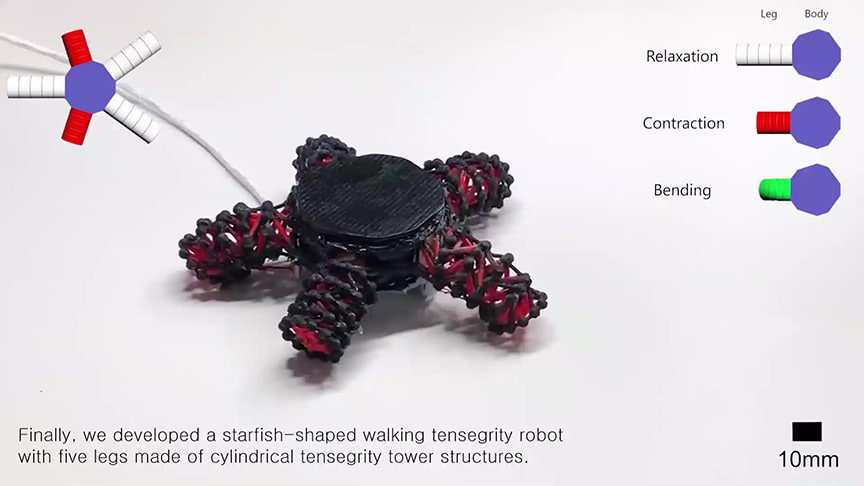

A South Korean research team from Ulsan National Institute of Science and Technology, has combined all three of those components into one project, in the form of a robotic starfish that moves just like a real one (kinda).

You can see the little robot below. Note the mesh-like structures in the legs of the starfish. Those are the tensegrity parts.

It achieves this feat of biomimicry by use of tendons arranged as a tensegrity structure. That is, a structure that is undergoing compression by virtue of a network of members in tension.

You may have seen the effect in various works of art, or even on social media recently, as people have been using tensegrity principles to design artworks and trinkets.

If an image is worth a thousand words, then hopefully this video can demonstrate the concept of tensegrity a lot quicker than our word count will allow. Note in the video that the entire structure seems to be in compression on those thin threads, which seem to be miraculously standing rigid as the weight bares down on them. But they aren’t in compression: they are in tension. It all balances out.

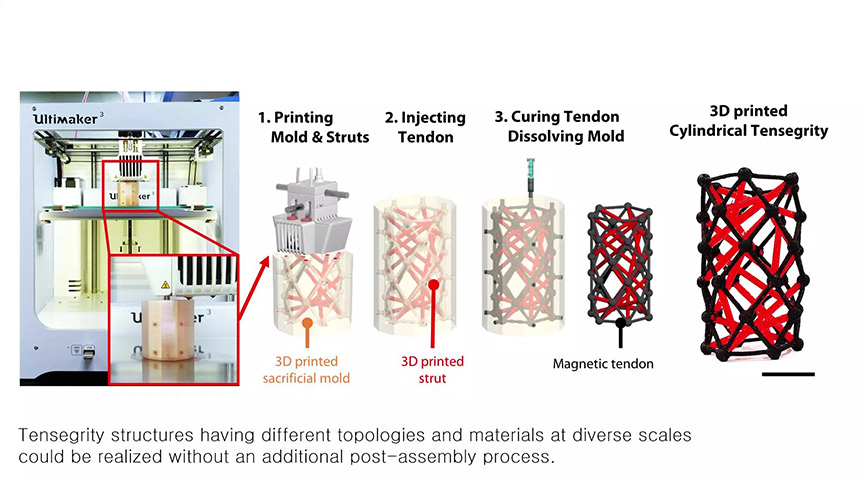

In the case of the starfish robot, these tendon networks have been created by use of a 3D printed sacrificial mold. The mold is printed with the cavities for the tendons and the rigid structures. When the mold is complete a resin is injected into the mould, and when the tendon network has cured, a dissolving agent is used to dissolve the mold, leaving only the network of tendons and rigid members remaining. The graphic below explains that.

The injected tendons actually comprise of a smart-material, which is magnetic. By manipulating the magnetic actuators electrically, the entire tensegrity system can flex and move and deform. Multiply that system 5 times, you have a rudimentary locomotion system, just like a starfish.

Soft robotic systems can be a little tricky to manufacture, so this demonstrates how assembly steps can be reduced by use of bog-standard desktop 3D printing combined with molded components integrated in the same manufacturing step.

So what are the applications of soft robots (of the tensegrity kind or otherwise)?

Researchers often state the malleability of soft robotics as being beneficial to search and rescue situations where a human being may not be able to access due to space constraints and hazards. Soft robots are often touted for use in space exploration, where the payload volume is at a premium.

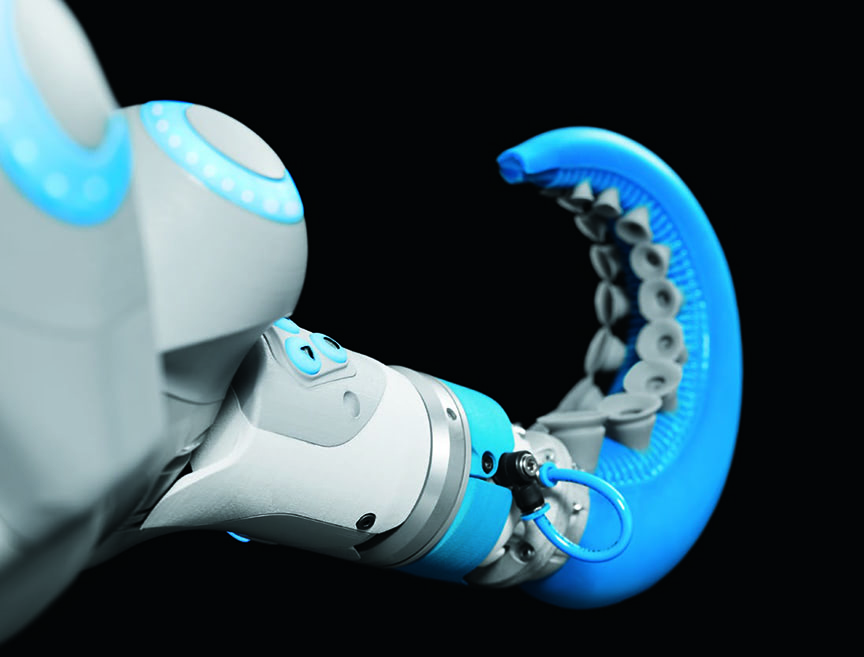

Cobots (collaborative robots) are also getting more “softer”, as it is a health and safety requirement to not have humans working next to robots with hard mechanical limbs flying around. There is ongoing research into soft-graspers as well, which fit onto traditional (hard) robotic arms, and provide a dynamic end-effector that can mold its shape to a variety of geometries compared to a traditional robotic “claw”.

It is conceivable that soft robots may find themselves in the workplace very soon, either as complete systems or as end effectors, like the Festo TentacleGripper soft end-effector in the picture below.