Do you fancy printing yourself some wireless sensor devices for use in your IoT or robotics applications?

If the answer is “yes”, or even “maybe”, then we have good news for you, because some researchers at Simon Fraser University, British Columbia, have just published a paper taking a look at the various methods for doing so.

The paper, which has been published in the ACS Applied Electronic Materials journal, takes a look at several different types of physical sensor including pressure, strain and temperature sensors. In addition, chemical type sensors such as biomedical and environmental sensors are examined. These sensors are intended to be used as part of wireless sensing systems such as RF and RFID tags.

As well as summarizing the various printed sensor types, the researchers examine the various types of printing methods with which you can print the various sensors.

Let’s take a look at some of them.

Pressure

Mechanical pressure sensing has applications in a wide range of domains ranging from posture recognition, to monitoring pressure in aerospace vehicles, to measuring fluid tank pressurization.

Sensing mechanisms for pressure sensing include resistive or capacitive measurement methods. When pressure is applied to the sensor, the change in resistance or capacitance can be monitored wirelessly. Via experimentation, the relation between applied pressure and changes in resistance or capacitance can be monitored and used in the desired applications.

These sensors are relatively simple, requiring just a track of conductive material that changes resistance or capacitance when the force is applied.

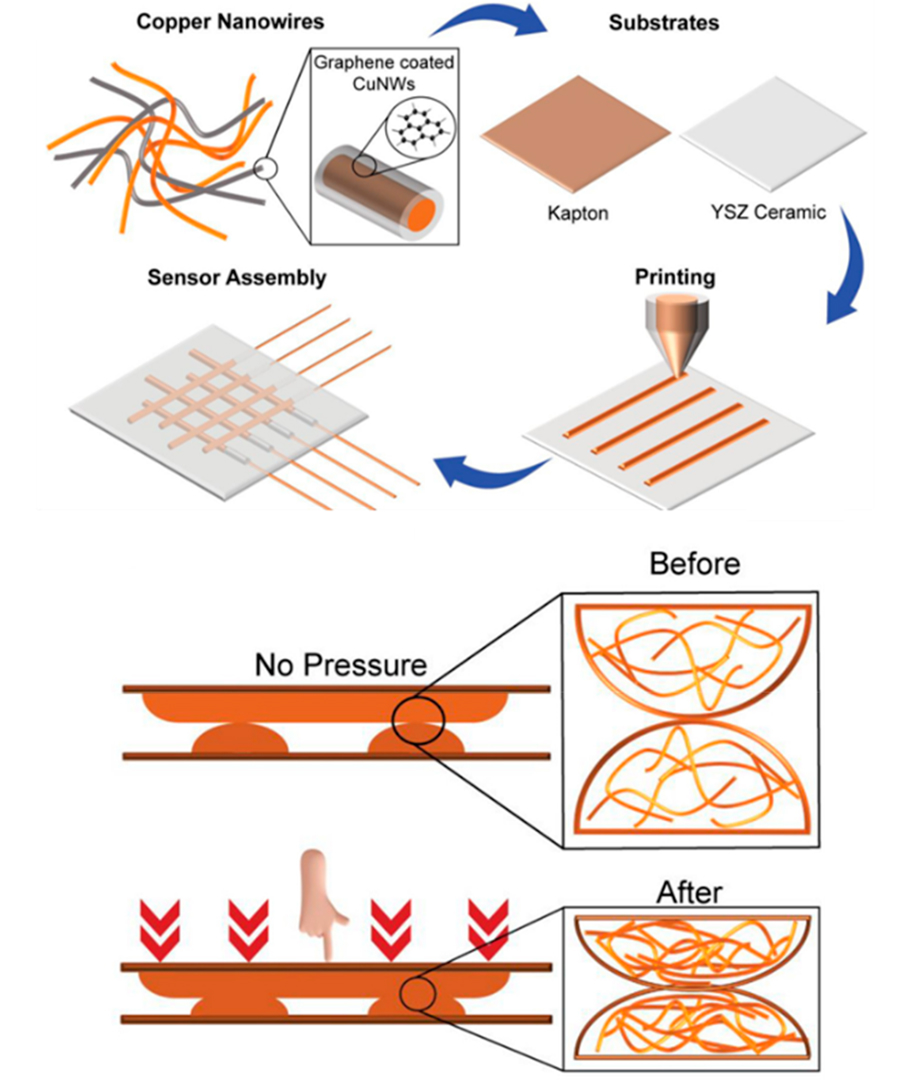

You can see one such example in the image below, that uses copper nanowires extruded with a direct writing method onto a flexible substrate. When the pressure was applied to the sensor, the printed copper nanowires became deformed, and the contact area between the adjacent nanowire geometries increased, leading to a decrease in resistance. The resistance change was monitored in a resonant circuit and those values were recorded wirelessly.

The printing method permitted the easy fabrication of the sensors in larger quantities at low cost.

Temperature

Temperature sensing is obviously fairly important, and the ability to do it wirelessly has benefits especially in hazardous or isolated environments. One example in the paper makes use of printed dipole antennas.

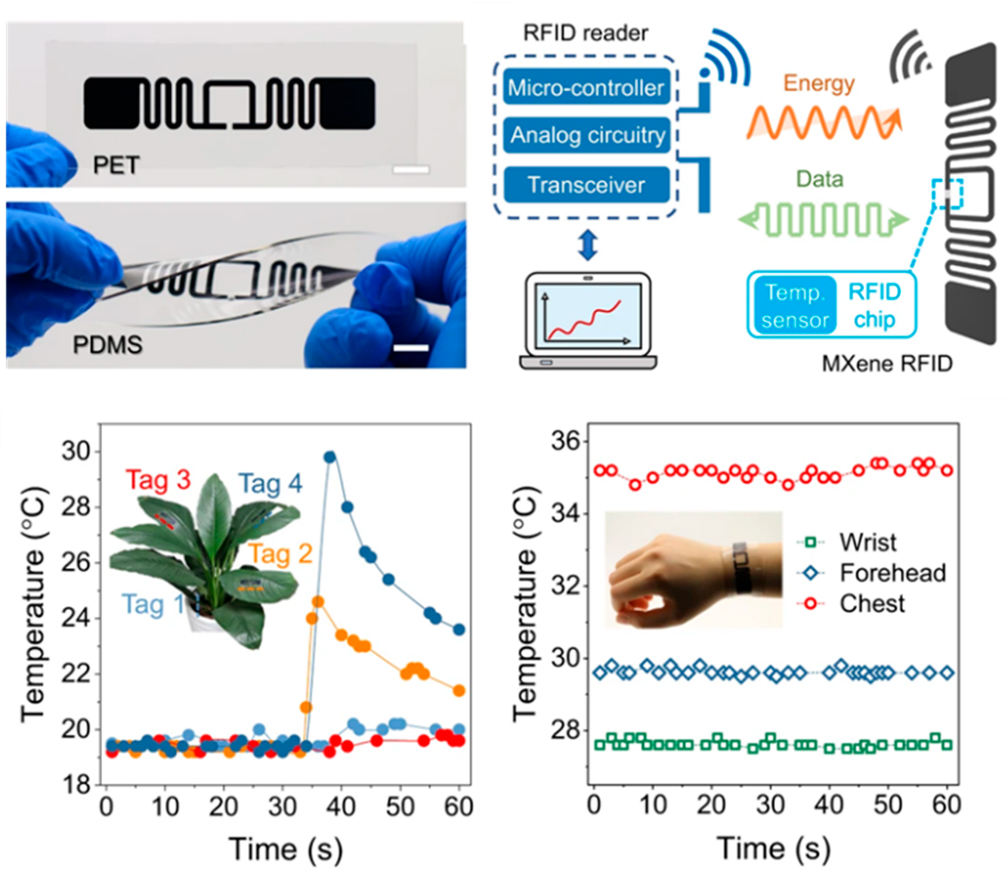

By using the direct ink writing (DIW) printing method one team of researchers printed an RF dipole antenna on polyethylene terephthalate (PET) and PDMS substrate.

They then added a temperature reading chip to the RF dipole antenna to achieve temperature measurement, which was communicated with a reader antenna. This setup was used to monitor the temperature of plant leaves (seen above).

Biomedical

Low cost biomedical sensors are useful, especially in these days of wearables and smart medical devices. Nobody wants to carry a heavy battery and computer around all day, afterall.

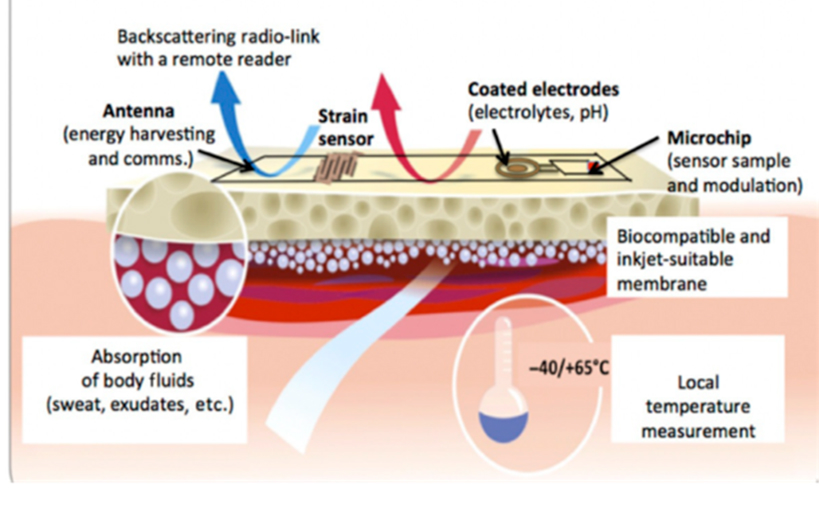

One of the printed sensors in the paper makes use of a printed RF sensor patch with multiparameter sensing. The transponder includes a miniaturized antenna for energy harvesting and communication with a remote RF interrogator, a microchip for data sampling and signal modulation, and several sensing elements.

The sensing elements are printed on a biocompatible membrane that can absorb biofluids such as sweat or drugs as they are released. The resulting epidermal wireless RF sensor can perform different sensing of local skin features such as temperature, strain, sweat loss, and pH.

Regional body temperature, strain, and pressure can also be detected as part of the mini sensor suite.

The summary paper looks at multiple examples of various sensors that may be of interest to researchers, and the authors note that there are still certain limitations for the printed RF sensors.

Low conductivity of printed inks is one of the biggest hurdles. This can be overcome with post processing such as electroplating, but this must be factored in when considering the cost to benefit ratio of such things.

The researchers conclude that the optimum path for this area of research is to focus on development of highly conductive and reliable inks.

You can read the paper titled “Printed Wireless Sensing Devices using Radio Frequency Communication” over at this link.