MIT engineers have developed a new 3D printing resin that forms two different types of solids depending on the light used. The material creates sturdy structures under ultraviolet light while producing easily dissolvable supports under visible light. This advancement eliminates the need to manually remove support structures, potentially increasing efficiency in 3D printing processes for customized products like hearing aids and dental implants.

The new method allows printed supports to dissolve in various food-safe solutions, including baby oil. Notably, the supports can even dissolve in the main liquid ingredient of the original resin, enabling continuous recycling of the support material. Once dissolved, the mixture can be blended back into fresh resin and reused for future prints.

“You can now print — in a single print — multipart, functional assemblies with moving or interlocking parts, and you can basically wash away the supports,” says Nicholas Diaco, a graduate student involved in the research. “Instead of throwing out this material, you can recycle it on site and generate a lot less waste. That’s the ultimate hope.”

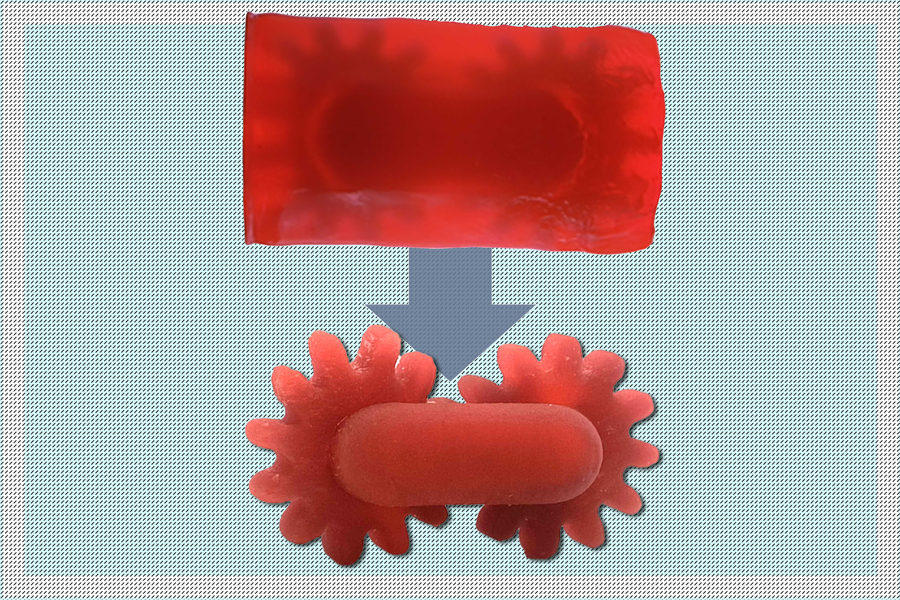

The team created the dual-phase resin by mixing two commercially available monomers with a third “bridging” monomer that links the materials together under UV light. This combination enables simultaneous printing of durable structures and dissolvable supports using timed pulses of UV and visible light in a single production run.

Researchers successfully demonstrated the technique by printing complex items including functional gear trains, intricate lattices, and a ball within a square frame. Professor John Hart, head of MIT’s Department of Mechanical Engineering, noted, “We’ll continue studying the limits of this process, and we want to develop additional resins with this wavelength-selective behavior and mechanical properties necessary for durable products.”

The research was supported by several organizations including the Center for Perceptual and Interactive Intelligence in Hong Kong, the U.S. National Science Foundation, the U.S. Office of Naval Research, and the U.S. Army Research Office. The full study appears in the journal Advanced Materials Technologies.

Source: news.mit.edu