Researchers at the Beckman Institute for Advanced Science and Technology have developed a new 3D printing method called “growth printing” that operates at speeds of 1 millimeter per second. The process, detailed in the journal Advanced Materials, creates polymer parts without requiring molds or expensive equipment typically associated with traditional manufacturing methods.

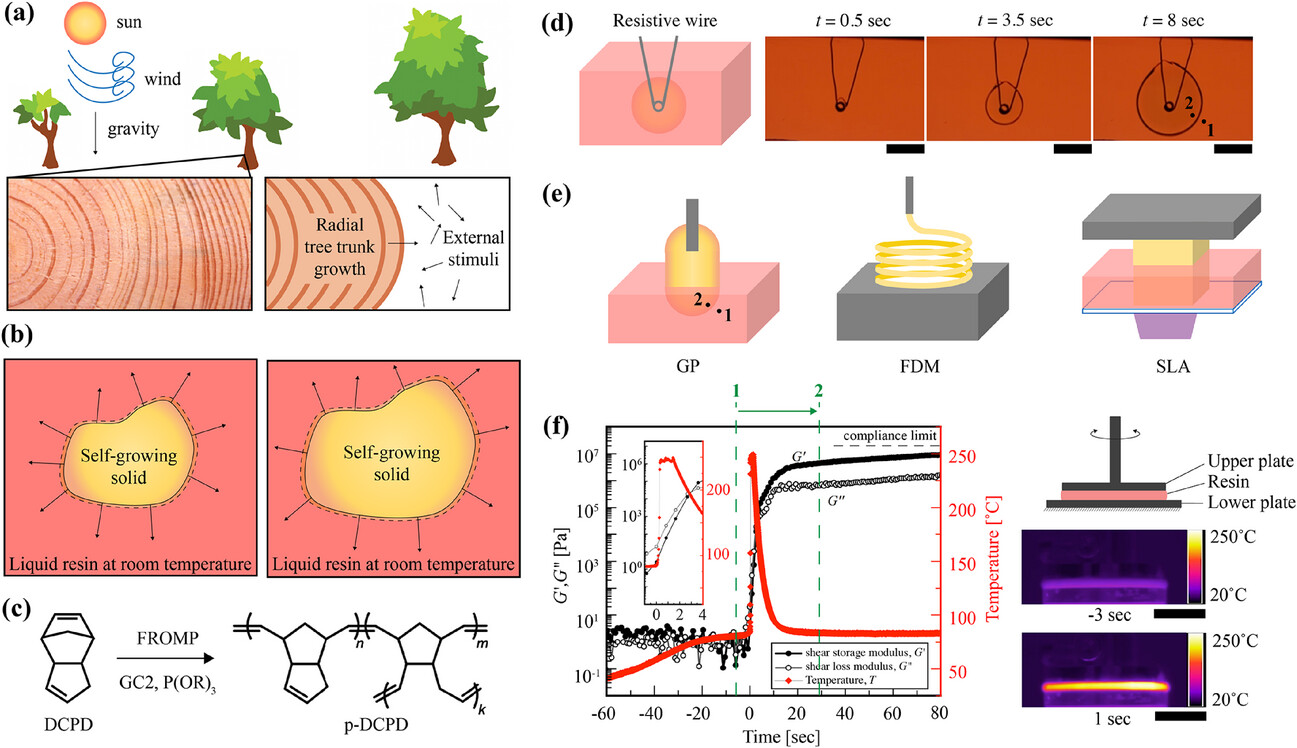

The technique involves heating liquid resin (dicyclopentadiene) at a central point to 70C, causing a reaction that spreads outward and hardens the material. This self-sustaining process, known as frontal ring-opening metathesis polymerization (FROMP), operates at speeds approximately 100 times faster than desktop 3D printers and uses minimal energy to create solid objects.

The method allows manufacturers to shape objects by manipulating the hardened material as it emerges from the liquid resin. Researchers can lift, dip, or spin the solid part to create various forms, similar to working with blown glass. The process has successfully produced symmetrical objects such as pinecones, raspberries, and squashes.

Professor Sameh Tawfick, the project lead from the University of Illinois Urbana-Champaign, sees potential applications for large polymer-based products like wind turbine blades. The research, funded by the U.S. Department of Energy Office of Science Basic Energy Sciences program, does have limitations – particularly in creating complex curved shapes or perfect geometric forms like cubes.

The team’s findings demonstrate an alternative to traditional injection molding, which can be costly and impractical for large objects. While the technology shows promise for manufacturing applications, it currently works best with axisymmetrical shapes and faces challenges when producing more complex geometries.

Source: sciencedaily.com