Researchers at the FAMU-FSU College of Engineering are developing tools that use artificial intelligence to identify defects in powder-based metal 3D printing. The $2.2 million project, funded by the Air Force Office of Scientific Research, focuses on binder jetting technology. This 3D printing method uses liquid binder to join powdered materials and is valued for creating complex metal components with higher productivity than other metal printing processes.

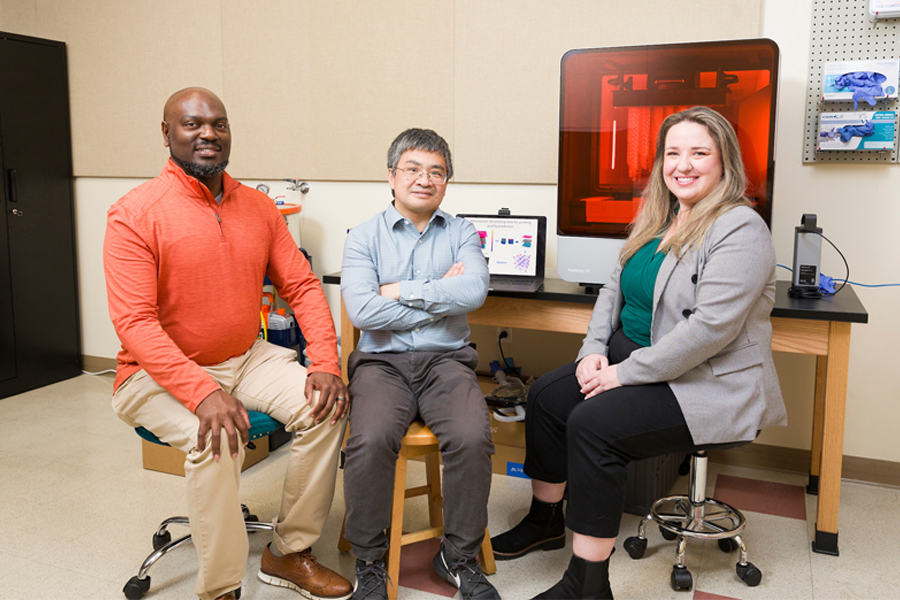

The research team, led by Associate Professor Hui Wang, is applying combinatorial generalization (CG) to improve defect prediction models. “Combinatorial generalization represents a computational reasoning capability that supports next-generation AI by mimicking human recognition behavior that generates new knowledge from data,” Wang said. The project aims to address porosity issues that commonly occur in powder-based fabrication.

Powder-based 3D printing serves numerous industries including aerospace, automotive, healthcare, and military applications. The researchers are collaborating with Pennsylvania State University and HP Inc. to advance this technology. Penn State is contributing simulations and XCT data modeling, while HP is providing access to data from their 3D Printing and Digital Manufacturing Center of Excellence.

The project offers significant educational opportunities for students. FAMU-FSU doctoral and undergraduate students have participated in HP internships, gaining practical experience in the field. The funding also helps researchers acquire essential experimental materials and small-scale testing equipment for the college.

“This technology could democratize manufacturing, making it easier for inexperienced manufacturers to advance from lab testing to large-scale production,” Wang explained. Beyond manufacturing applications, the research has potential benefits for system maintenance and cybersecurity. The interdisciplinary approach combines expertise in industrial and manufacturing engineering with new AI capabilities.

Source: news.fsu.edu