The spinal implant industry is a huge adopter of additive manufacturing due to the highly bespoke requirements for spinal implants. And it is a sector that continues to innovate at an astounding pace.

It was just two years ago when we did this story on how topologically optimized printed titanium spinal cages are helping patients. These cages are used to replace the disks between vertebrae after surgery.

Now a team of researchers at University of Pittsburgh Swanson School of Engineering has gone further and added the ability to monitor patient health with the spinal implants, by use of metamaterials in the printing process. This smart spinal implant uses what the researchers are calling “meta-tribomaterials”, which can generate their own power and can be used for a wide array of sensing and monitoring applications.

The prefix “tribo” generally indicates some kind of rubbing/friction movement, so that gives you some kind of indication of the mechanism at work here. Indeed, according to the research paper, it utilizes something called a built-in triboelectric nanogenerator (TENG) to power itself. By self powering, the implant overcomes several limitations of current smart implants that rely on batteries to power them (short life being one such hurdle).

“Smart implants can provide real-time biofeedback and offer many therapeutic and diagnostic benefits,” said Amir Alavi, assistant professor of civil and environmental engineering.

“But it is very challenging to integrate bulky circuits or power sources into the small area of implants. The solution is to use the implant matrix as an active sensing and energy harvesting medium. That’s what we’ve been focused on.”

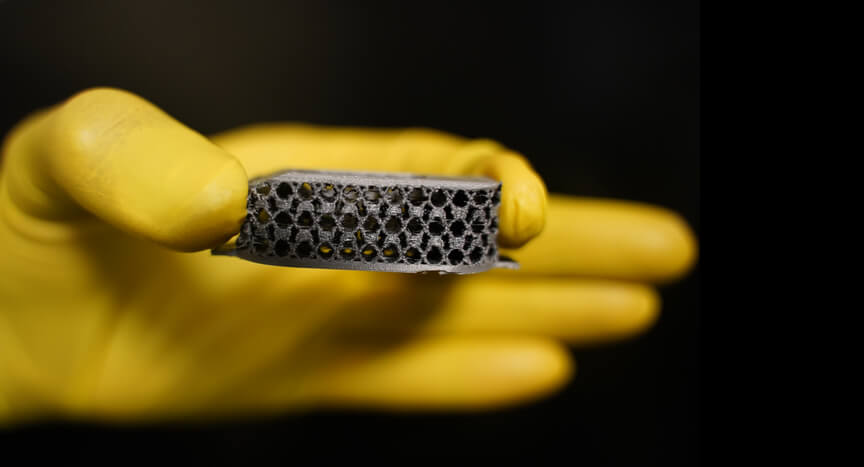

In the research, TPU and PLA with carbon black were used to fabricate the dielectric and conductive layers of the fusion cages. This combination maximized the electrification between the layers. When they flex together with human motion, the matrix forms contacts between the layers, and this generates voltage and also provides sensory data to the implant.

The parts were printed on a Raise3D Pro2 Dual Extruder 3D Printer, with both materials being deposited during the same print job.

Alavi is also head of the Intelligent Structural Monitoring and Response Testing (iSMaRT) Lab who are heading the research at the University of Pittsburgh, and his lab has developed a new class of multifunctional mechanical metamaterials, which act as their own sensors, recording and relaying important information about the pressure and stresses on its structure.

Sounds a little bit like this little piezoelectric robot from last week. That robot also used metamaterials for sensing…

“Spinal fusion cages are being widely used in spinal fusion surgeries, but they’re usually made of titanium or PEEK polymer materials (a semi-crystalline, high-performance engineering thermoplastic) with certain mechanical properties,” said Alavi.

“The stiffness of our metamaterial interbody cages can be readily tuned. The implant can be 3D-printed based on the patient’s specific anatomy before surgery, making it a much more natural fit.”

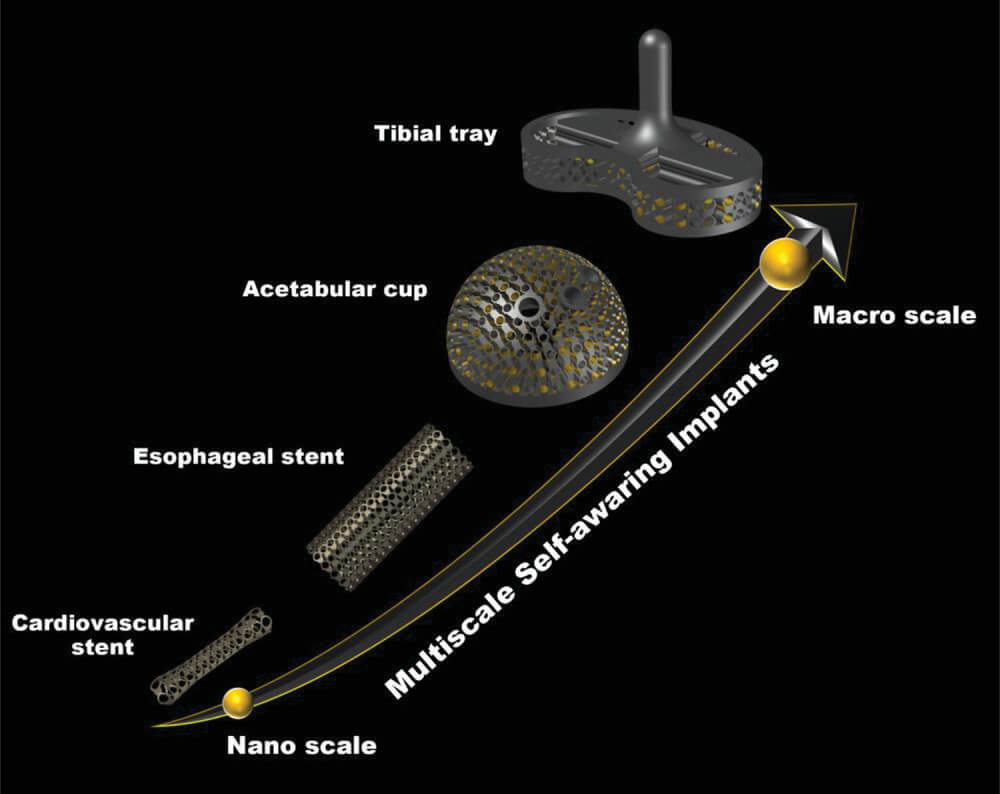

The research showed that under loading conditions similar to the human lumbar spine, the plastic fusion cage prototype could generate voltage and current values equal to 9.2 V and 4.9 nA, respectively. The method of printing these plastic materials is also scalable and the researchers state that it can be used for a variety of implants at different scales, as you can see in the image above.

The paper ( “Patient-Specific Self-Powered Metamaterial Implants for Detecting Bone Healing Progress”) showing the research was published in the journal Advanced Functional Materials, and you can find it at this link.