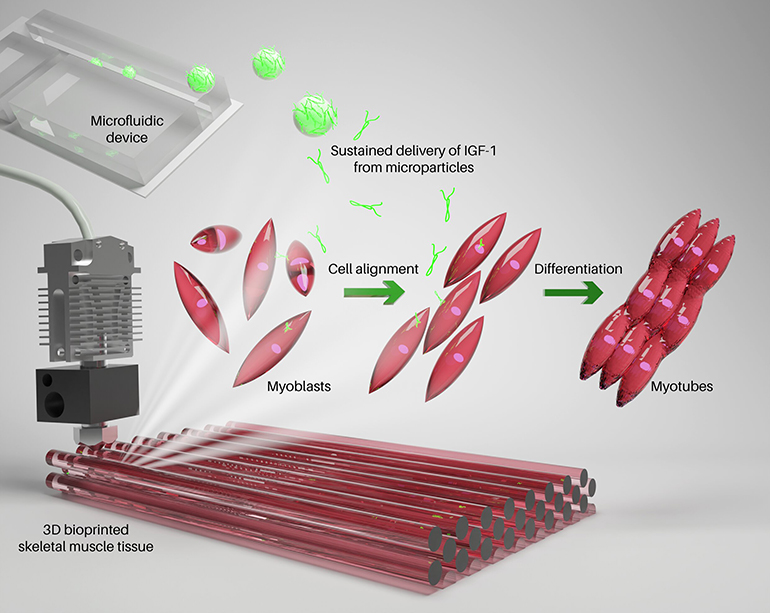

Researchers at the Terasaki Institute in Los Angeles have pioneered a new approach to advance 3D bioprinted muscle constructs, offering hope for more effective muscle transplants in the future. Their method involves incorporating microparticles loaded with insulin-like growth factor (IGF) into a bioink containing myoblast cells and a gelatin-based hydrogel.

The integration of IGF-loaded microparticles, achieved through a microfluidic platform, has yielded impressive results. After 3D printing, the muscle constructs exhibit significant improvements in cell growth, elongation, and alignment. In some instances, these engineered muscles even exhibited spontaneous contractions after just ten days of incubation. This achievement marks a promising step toward the development of fully functional lab-created muscle transplants for patients in need.

The significance of this work lies in addressing the critical role of skeletal muscle in human mobility and daily life. When injuries or diseases necessitate the removal of muscle tissue, it profoundly impacts a patient’s quality of life. Traditional treatments involve invasive procedures, such as transplanting healthy muscle from other areas of the body, which can lead to complications and incomplete recovery.

By leveraging 3D bioprinting and slow-release growth factors like IGF, researchers are steering myoblast cells toward a skeletal muscle phenotype within the constructs. This approach mimics the natural behavior of muscle cells, fostering elongation and alignment.

“The sustained release of IGF-1 facilitates the maturation and alignment of muscle cells, which is a crucial step in muscle tissue repair and regeneration,” said Ali Khademhosseini, a researcher involved in the study.

“There is great potential for using this strategy for the therapeutic creation of functional, contractile muscle tissue.”

The potential for engineered muscles to contract further underscores the promise of this technology, which is paving the way for more effective and less invasive muscle transplants, offering hope for improved outcomes and quality of life for patients facing muscle-related challenges.

You can read the research paper titled “Enhanced Maturation of 3D Bioprinted Skeletal Muscle Tissue Constructs Encapsulating Soluble Factor-Releasing Microparticles” at this link.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.