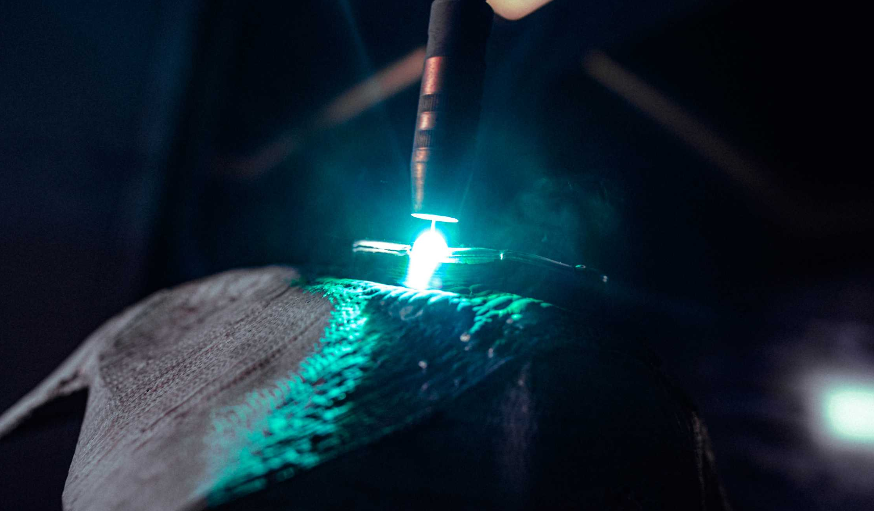

BMW Group has unveiled its new approach to producing metallic vehicle components using Wire Arc Additive Manufacturing (WAAM). This method involves melting aluminum wire with precision, enabling the creation of lighter, more rigid parts with reduced energy consumption and material waste. Initial trials show promising results, with plans to integrate WAAM components into production vehicles by 2025.

The WAAM process, conducted at BMW’s Additive Manufacturing Campus, offers rapid production of large components suitable for body, drive, and chassis areas. Despite slightly rippled surfaces, WAAM components demonstrate high durability, even under cyclical loads, eliminating the need for extensive post-treatment.

BMW’s focus on generative design further enhances WAAM’s potential by optimizing component design based on specific requirements. This collaborative effort between interdisciplinary teams and evolutionary-inspired algorithms results in lighter, more efficient components with improved vehicle dynamics.

“It’s impressive to see how WAAM technology has developed from research to become a flexible tool for not only test components but also series production components,” said said Karol Virsik, Head of BMW Group Vehicle Research.

“The use of generative design methods enables us to make full use of design freedom and thus the potential of the technology. That was unthinkable just a few years ago.”

While WAAM complements existing additive manufacturing processes like laser beam melting, it excels in producing large components quickly. BMW plans to centralize WAAM production initially, with future expansion to other locations and potential integration into supplier networks.

This approach not only accelerates production processes but also enhances sustainability by reducing emissions and minimizing material usage.

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.