Scientists at Caltech have created a new technique that allows precise control over the composition and structure of metal alloys through 3D printing. The method builds on the team’s previous work with hydrogel-infusion additive manufacturing (HIAM), extending it to create alloys with custom percentages of different metals. The research was published in the journal Small, with Thomas T. Tran as lead author and Rebecca Gallivan as second author.

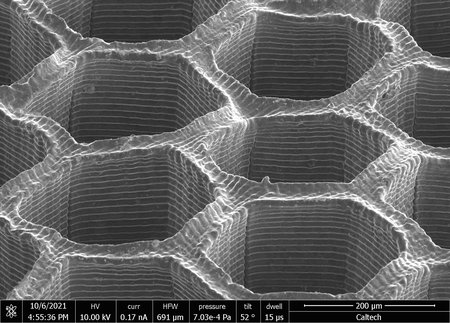

The process begins with 3D printing an organic hydrogel scaffold, which is then infused with metal ions from liquid metallic salt solutions. Scientists burn away the organic material in a process called calcination, leaving metal oxides behind. In the final step, called reductive annealing, the material is heated in a hydrogen environment to remove oxygen and form the desired metal alloy structure.

“The composition can be varied in whatever manner you like, which has not been possible in traditional metallurgy processes,” says Julia R. Greer, the Ruben F. and Donna Mettler Professor of Materials Science, Mechanics and Medical Engineering at Caltech. The team demonstrated this control by creating copper-nickel alloys with different ratios, finding that a Cu12Ni88 alloy was nearly four times stronger than a Cu59Ni41 alloy.

Analysis using transmission electron microscopy revealed that the HIAM process creates more uniform crystal structures compared to other methods. The technique also leaves tiny oxide inclusions within the alloys that contribute to their strength. “Because of the complex ways in which metal is formed during this process, we find nanoscale structures rich with metal–oxide interfaces that contribute to the hardening of our alloys by up to a factor of four,” Tran says.

The research shows that alloy strength depends on both grain size and composition, challenging previous assumptions about metal strength factors. The work was supported by the US Department of Energy’s Basic Energy Sciences program and a National Science Foundation graduate fellowship.

Source: caltech.edu