Dalhousie University has partnered with Defence Research and Development Canada (DRDC) to address critical parts supply challenges for Canada’s aging submarine fleet. The collaboration focuses on developing additive manufacturing processes for naval components as Canada prepares to replace its Victoria-class submarines, which are scheduled for decommission in the mid-2030s. Until new submarines arrive, expected around 2035, maintaining the current fleet remains essential for military readiness.

The project tackles a significant logistical problem: sourcing replacement parts for decades-old submarines when original manufacturers may no longer exist. Cameron Munro, a defence scientist with DRDC at Halifax’s Atlantic Research Centre, explains the current situation: “If you need to replace a part on a submarine that was built 35 years ago, you may find that the manufacturer no longer exists.” Traditional procurement methods for custom components can take years, creating delays that impact operational readiness.

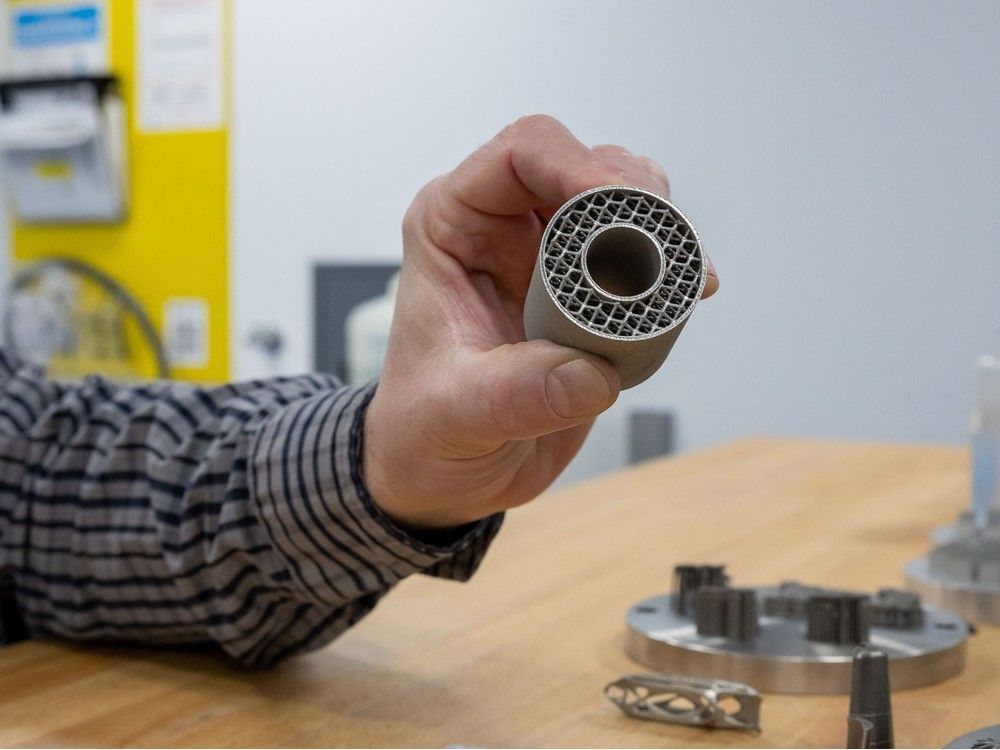

Materials engineer Dr. Paul Bishop is leading the research at Dalhousie, utilizing specialized 3D printing techniques to fabricate metal components directly from powders. “Dalhousie has designed and commissioned an exceptionally comprehensive suite of infrastructure for this technology — globally competitive and nationally unique,” says Dr. Bishop. The university’s research team is pioneering work with defense-standard naval alloys that have never before been studied for additive manufacturing applications.

The partnership positions Dalhousie as an intermediary between DRDC and Canadian manufacturers. By developing fundamental “recipes” for materials and processing parameters, the university creates specifications that companies can implement without extensive research investment. This approach allows the Royal Canadian Navy to maintain ownership of the research and avoid dependency on single suppliers for critical components.

According to Munro, the project extends beyond immediate needs: “This project isn’t just about making one or two components — it’s about building long-term industrial capacity in Canada.” The initiative aims to enable on-demand production of parts rather than maintaining large inventories, potentially reducing costs while ensuring availability. The research is supported by NSERC, the Canadian Foundation for Innovation, and industry partners.

Dr. Bishop emphasizes the knowledge transfer aspect of the collaboration: “The real goal is to provide the Navy and the supporting industry partners with data that define reliable processes that can be used at scale.” This approach supports greater self-reliance in maintaining Canada’s naval capabilities, with Munro noting, “We need to increase our ability to support Canada’s military platforms domestically.”

Source: dal.ca