Building wind farms has long been hindered by the logistical challenge of transporting massive wind turbine blades. However, a new startup, Orbital Composites, is poised to transform the industry with its use of 3D printing and robotics. The company’s CEO, Amolak Badesha, envisions a future where wind turbines are manufactured right at their installation sites, circumventing the arduous transportation process that has plagued the sector.

Orbital Composites has harnessed technology that enables rapid 3D printing of composite materials. Unlike the labor-intensive methods currently employed in wind blade production, this approach significantly reduces costs and waste. Traditional processes, once dominated by offshore factories due to their manual nature, have become outdated, while Orbital’s on-site manufacturing strategy promises to reinvigorate domestic production.

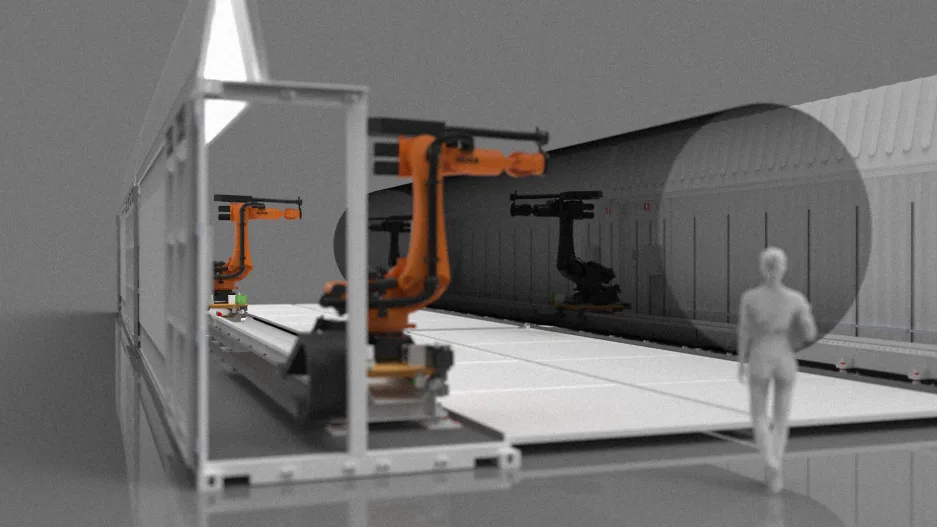

The startup’s technique involves crafting colossal molds through 3D printing and subsequently producing the wind turbine blades within these molds. The entire manufacturing setup can be transported in shipping containers, eliminating the need to move the finished product and allowing for the creation of larger blades. This innovation not only enhances energy output but also slashes manufacturing expenses, with anticipated cost reductions of up to 25%.

3D Printing Whole Turbines

Orbital Composites is also on a path to 3D print bases, towers, and other components for wind turbines. The company’s future collaboration with the Department of Energy to develop a cable-based 3D printing robot represents a big stride forward in on-site fabrication. This agile system will enable the creation of enormous blades without the need for extensive infrastructure, enabling wind energy on larger scales.

Orbital’s also plans to use recyclable materials, to further demonstrate its dedication to sustainability. With plans to create wind turbine blades that are not only recyclable but also reusable downstream, the startup is charting a greener course for the industry. The company will unveil its first 3D printed wind blade demonstration later this year

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.