Many of our readers have most likely heard of continuous carbon fiber printing systems making use of thermoplastics as a matrix. There are commercial systems capable of this on the market right now, and there have been for a while.

But did you know that it’s possible to combine VAT photopolymerization with continuous carbon fibers? By the end of this article, you will know it.

Read on to know more about the research into CONFIB-VAT (CONtinuous FIBer VAT photopolymerization)!

Research

A team of researchers from China and the UK have demonstrated huge increases in the mechanical properties of printed resin specimens with continuous carbon fibers embedded within them.

There are multiple means of adding chopped fiber into 3D printer feedstocks, be it a resin or filament based system. We even see continuous carbon fiber printing making use of thermoplastics, which in principle, is not especially complicated. Markforged have been doing it for years, by extruding their own thermoplastic-treated carbon fiber filaments via a heated nozzle. It works just like normal FFF thermoplastic printing, except the thermoplastic filament has a core of carbon fiber running along the entire length.

When the filament is extruded through the heated nozzle, it cools within a few milliseconds of hitting the previous layer, and that’s it. With thermoset resins though, it’s more challenging, as the carbon fiber piece cannot hold onto the resin while it is on the spool – because it’s liquid!

The researchers from Hunan University, Nanjing University of Aeronautics and Astronautics and Loughborough University have found a fairly simple solution to the problem of encasing CF fibers into a resin matrix – they simply pause the resin printer at a particular layer, manually drop a carbon fiber tow onto the resin part, then resume printing over it.

Groove is in the…Part?

If you attempt to drop a carbon fiber tow into a VAT while the resin is in the liquid state, there will be some difficulty in keeping that fiber aligned in the precise manner needed for building functional composite parts. They have a tendency to move around while printing, and that’s not good.

To combat this, the researcher designed their CAD models to have a groove in them. When the z-axis moves the part to this particular layer, the print is paused, and the tow is placed into the groove, before printing is resumed.

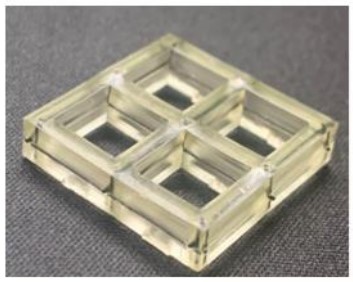

After the printing and embedded process was completed, the finished part was placed into

a G2 Light Curing Box to cure any unreacted solvents.

You can see a completed resin part with the embedded CF tows in the image below.

With just 10% carbon fiber content embedded in the resin matrix, it was demonstrated that the sample parts had more than a 500% increase in ultimate tensile strength. According to the research paper, the fiber volume content could reach up to 33.46% with their current method, which is very close to the volume content used in commercial products. The researchers state that the fiber content could be increased even further.

Fiber Shielding

There was one observable defect that the researchers were interested in studying further, and this was the effect of fiber shielding on the resin beneath the fiber.

It was observed that after the fiber is placed, this would mask the printed resin part beneath it, effectively placing the geometry under the fiber into a shadow area. This resulted in uncured areas of the part directly under the fiber which in turn led to a weakening of the final part.

It was shown that this could also be partly rectified by placing it into the curing box after printing, the results of which considerably improved the mechanical properties of the test specimens.

The team were able to also embed fibers in different orientations in all three planes, X, Y and Z, and in all three planes simultaneously, which allowed for greater flexibility in fiber arrangement and composite design.

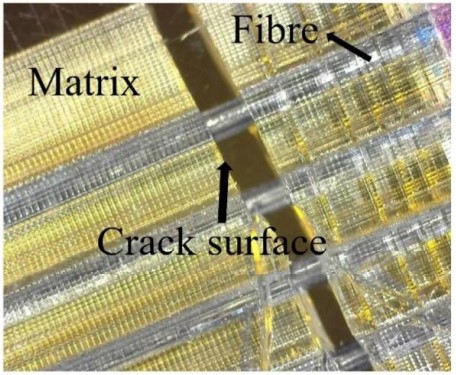

The tensile testing showed that during part failure in the tensile tests, the matrix was the first to fracture, leaving the carbon fiber tows intact and carrying the full load. You can see an example of that in the image below.

The researchers hope that their work could pave the way for the future development of commercial hybrid composite / VAT photopolymerization systems.

Their paper, titled “Continuous fibre reinforced Vat photopolymerisation (CONFIB-VAT)“ is currently in pre-proof and will be published in the Additive Manufacturing journal shortly.