NASA’s Nebraska Space Grant office has just issued Copper3D a research grant for thermoplastic printing applications in space. Both organisations are looking test the antimicrobial properties of Copper3D’s PLACTIVE 3D printer filament at the International Space Station. The research could be a massive boon in developing medical devices for long-term interstellar missions.

“Basically, our idea is to introduce to the 3D printing industry the concept of Active Materials”, Daniel Martinez, Director of Innovation and CMO of Copper3D explained. “These are materials that are no longer inert and only support structures but now they are active components that play a specific role and adds great value to the final 3D printed object, in this case the attribute is that these objects are completely antimicrobial.”

Antimicrobial 3D Printing

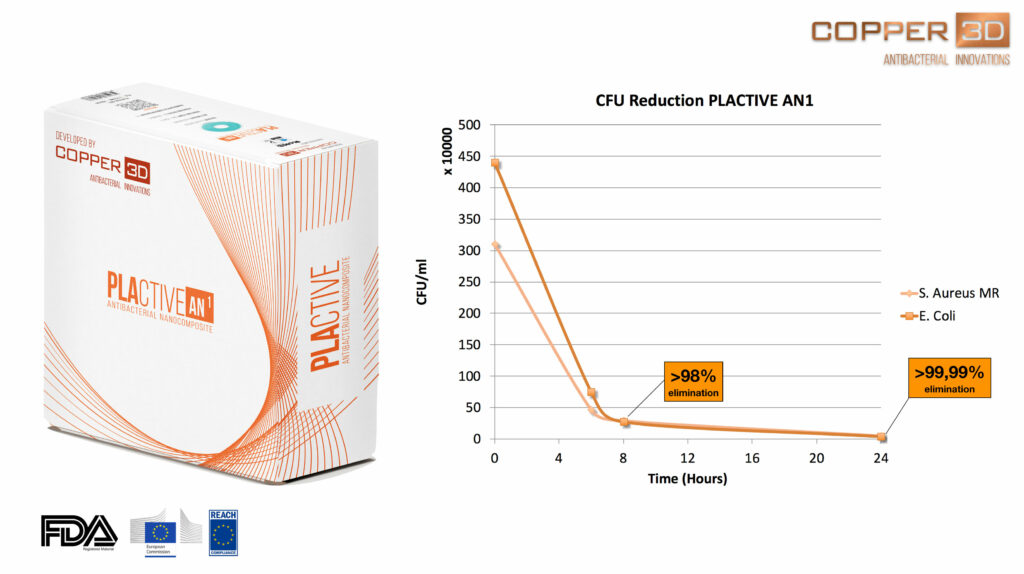

PLACTIVE AN1 is a Nanocomposite with high quality PLA and patented, scientifically validated and Nano-Copper additive. The filament boasts a 99% removal rate for fungi, viruses, bacteria and a range of other microorganisms. Labs across the US and Chile along with the FDA have tested the material to stunning success (as the graphic shows). The filament was also deemed ideal for prosthetics and medical devices for these very same properties.

It’s likely that NASA is looking to this project for insight into possible designs for Mars missions. Since printing on Earth can only provide loose simulations, printing in micro-gravity is the real test. A plethora of factors can be monitored in their effects on the material including radiation levels, multi-resistant microbes, stress and microgravity.

As many space-based projects do, there is a great trickle down effect of the research to more terrestrial research fields. Often, the ideas NASA discovers become staples of industries like medicine, which has benefited greatly from their cardiovascular research. It’s safe to say, this will have similar effects that benefit everyone.

Featured image courtesy of Copper3D.