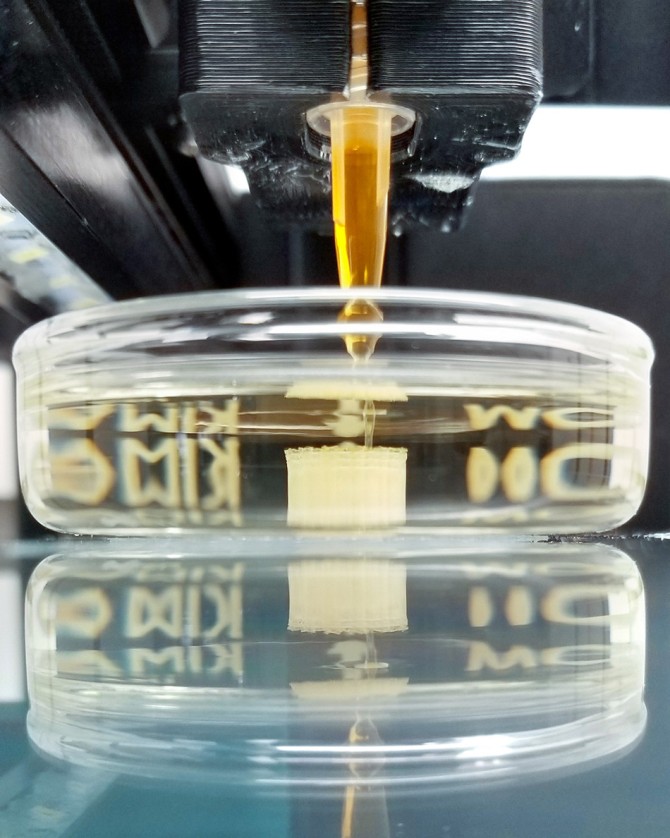

Cornell University researchers have developed a one-step 3D printing method that produces superconductors with improved properties. The research, published August 19 in Nature Communications, uses a copolymer-inorganic nanoparticle ink that self-assembles during printing and is then heat-treated into a crystalline superconductor.

The work builds on nearly a decade of research led by Ulrich Wiesner, Spencer T. Olin Professor in the Department of Materials Science and Engineering. In 2016, Wiesner’s team first reported self-assembled superconductors using block copolymers, and by 2021 showed these materials could match conventional superconductor performance. The new method could benefit applications including superconducting magnets and quantum devices.

The researchers’ most notable result involved printing niobium-nitride material, which achieved an upper critical magnetic field of 40 to 50 Tesla. This represents the highest confinement-induced value reported for this compound superconductor and is important for strong superconducting magnets used in applications like MRI imaging.

“What this paper shows is that not only can we print these complex shapes, but the mesoscale confinement gives the materials properties that were simply not achievable before,” said Wiesner. The approach differs from traditional 3D printing methods by eliminating several processing steps and creating materials with structure at three different scales: atomic, mesoscale, and macroscopic.

The method produces superconducting materials with record surface areas for compound superconductors, which could prove useful for quantum materials development. The researchers plan to explore alternative superconducting compounds and note that the technique can be applied to other transition metal compounds such as titanium nitride.

Source: news.cornell.edu