Researchers from The University of Texas at Austin, Sandia National Laboratories, and other national laboratories have developed a new 3D printing method that can create objects with varying properties on a pixel-by-pixel basis. The technique, called Crystallinity Regulation in Additive Fabrication of Thermoplastics (CRAFT), uses standard commercial printers and common materials to produce items with different levels of hardness and transparency. The research was published in the journal Science.

The CRAFT method transforms liquid cyclooctene resin into solid plastic objects by projecting grayscale light patterns onto a platform that moves through the liquid. This process builds objects from thin 2D polymer layers while controlling molecular-level order in three-dimensional space. “We can control molecular level order in three-dimensional space, and in doing so, completely change the mechanical and optical properties of a material,” said Zak Page, a UT associate professor of chemistry and author on the paper.

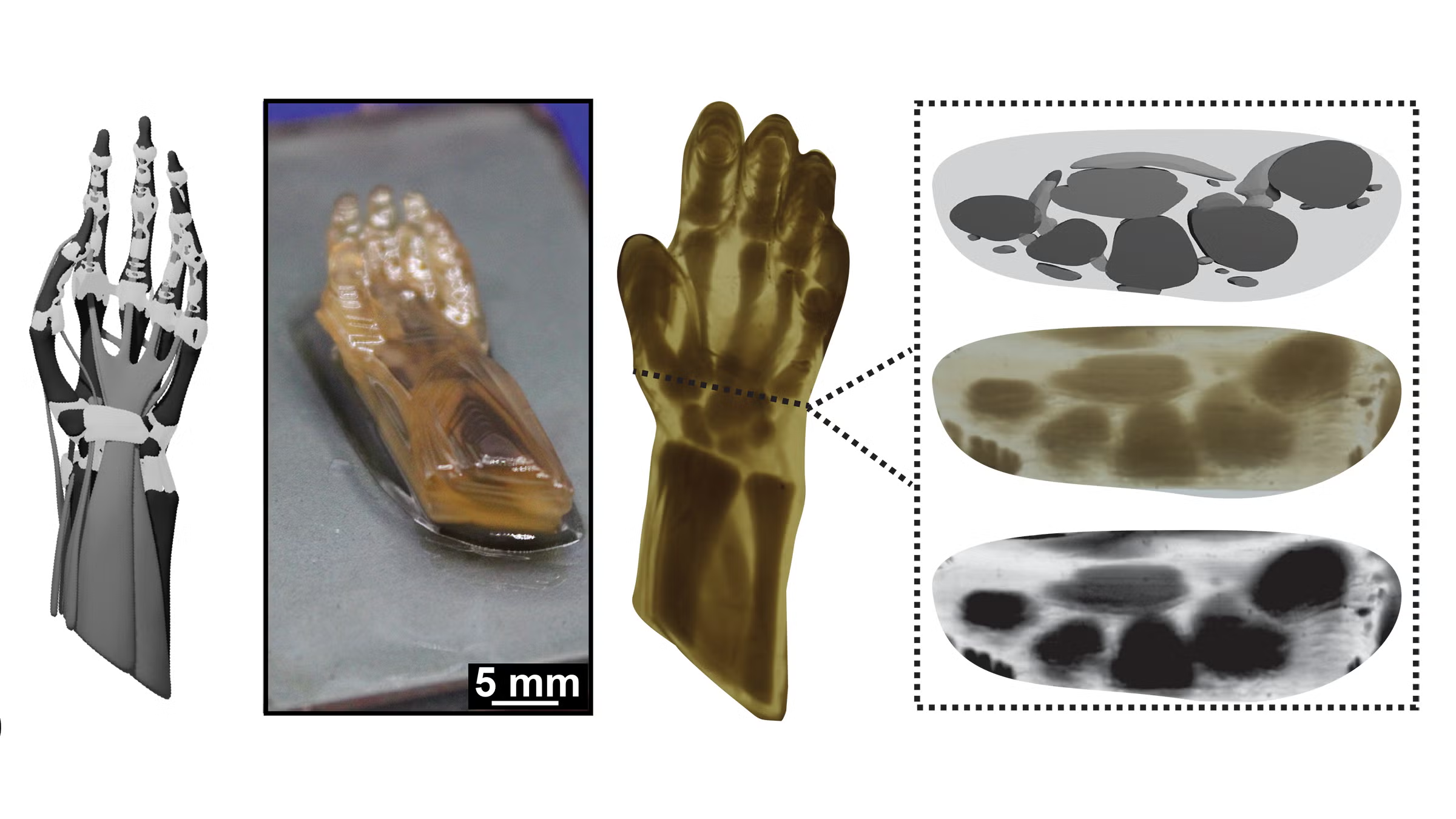

One potential application involves creating anatomical models for medical education. The method can simulate interconnected structures with properties ranging from bone to muscle tissue using a single feedstock material. Current 3D-printed medical models often use expensive inkjet printers and multiple materials that don’t adhere well together, creating unrealistic failure points at interfaces.

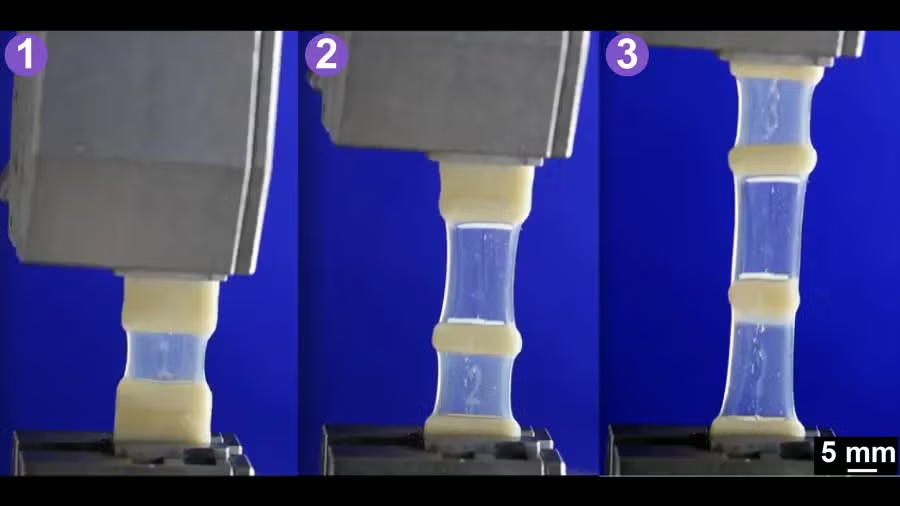

The technique could also be applied to energy damping applications such as soundproofing or protective gear. Page envisions developing materials with alternating hard and soft internal structures similar to natural materials like tree bark and bones. The method is compatible with DLP or LCD 3D printers, which Page notes can be purchased for $1,000 or less with grayscale projection capability.

The research was funded by the U.S. Department of Energy, the National Science Foundation, and the Robert A. Welch Foundation. The work was led by Alex Commisso and Samuel Leguizamon, both formerly at Sandia National Laboratories, with Leguizamon now at Savannah River National Laboratory and Commisso at Azul 3D.

Source: cns.utexas.edu