Sheffield University and Imperial College researchers are currently looking into the use of novel microstructures in prints to improve durability. They’ve uncovered possibilities in the use of crystallographic metamaterials for metal printing alloys with the use of computer atomic modelling. As a result of these crystal structures, the material itself comes out without grain boundaries, continuous and unbroken. This gives the end print better damage tolerance, strength and toughness.

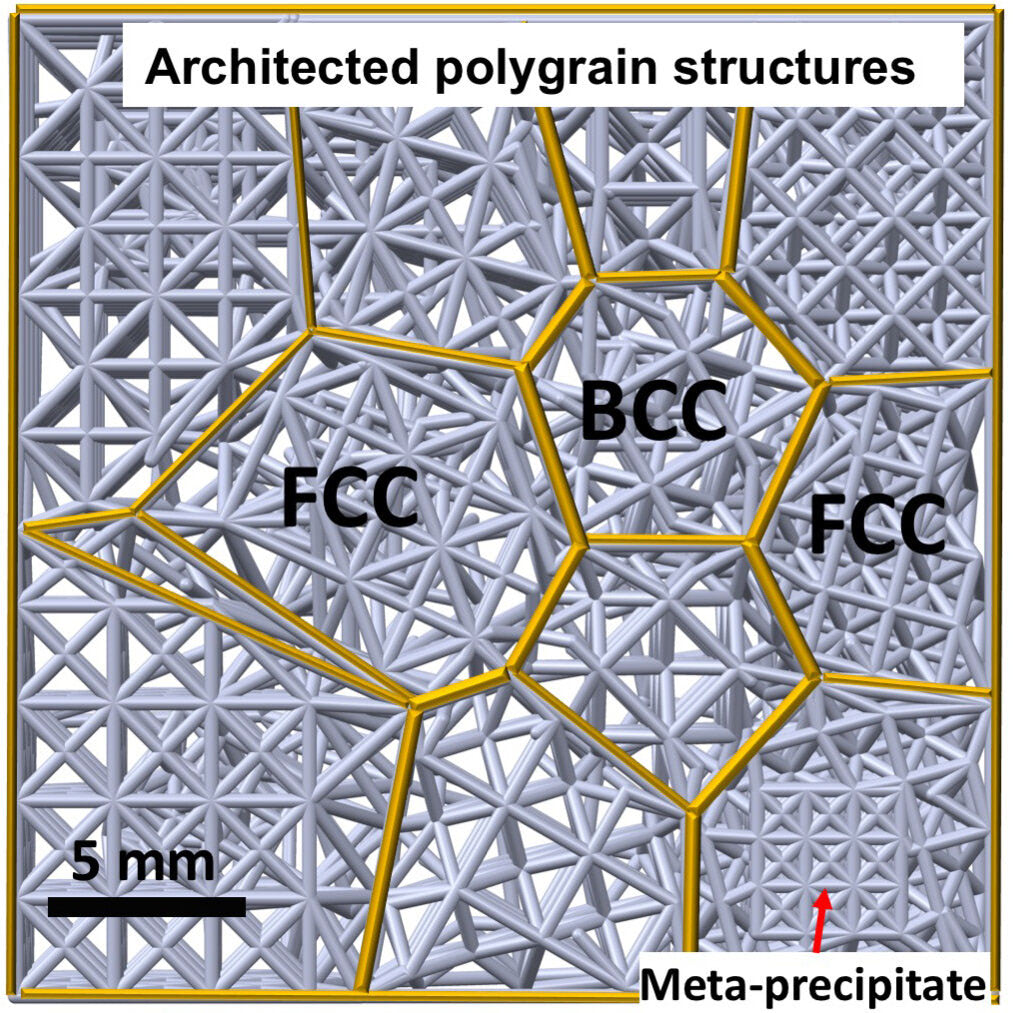

Microstructures and particularly architected lattices that allow for novel characteristics such as never before seen levels of rigidity. In this case, the researchers created ‘architected’ materials constructed from identical ‘unit cells’ arranged so that they all have the same orientation. Crystallographic Metamaterials and crystal-inspired mesoscale structures incorporate these uniquely arrangeable lattices.

According to the paper:

Architected materials that consist of periodic arrangements of nodes and struts are lightweight and can exhibit combinations of properties (such as negative Poisson ratios) that do not occur in conventional solids. Here we use the hardening mechanisms found in crystalline materials to develop architected materials that are robust and damage-tolerant, by mimicking the microscale structure of crystalline materials.

Metal Printing Architected Alloys

Polycrystalline materials have a very peculiar structure. Since they have many crystals, the alignment of the atomic planes is random. As a result cracks caused by forces emerging in particular direction will decelerate or stop when it faces a crystal. Thus, the structure has a level of durability that single-crystal structures can’t achieve. This was the main underpinning of the research and development of ‘meta crystals’, as the researchers call them.

“This meta-crystal approach could be combined with recent advances in multi-meta-material 3D printing to open up a new frontier of research in developing new advanced materials that are lightweight and mechanically robust, with the potential to advance future low carbon technologies,” said Dr Minh-Son Pham, Assistant Professor in the Department of Materials, ICL.

While the research is still young, early tests are very promising. Their computer models have the potential to alter the ways in which we design composites. Crystallographic metamaterials and structures with precise architectural control have a lot of durability, strength and energy absorption (up to seven times), and could be very useful in high stress engineering technologies such as aerospace and naval.

Featured image courtesy of University of Sheffield.