Danish Technological Institute and Heatflow have completed development of a 3D-printed cooling component for data centers through the AM2PC research project. The system achieved a cooling capacity of 600 watts during testing, exceeding the original target of 400 watts by 50 percent. The solution uses passive two-phase cooling technology that operates without pumps or fans.

The cooling system addresses growing energy demands in data centers, where GPU power consumption has increased from 100-200 watts to several hundred or even kilowatts in recent years. “Besides the actual IT hardware, the corresponding cooling infrastructure is one of the major energy consumers in a data center – and therefore the greatest potential to improve overall system efficiency,” explains Simon Brudler, 3D-printing specialist and senior consultant at Danish Technological Institute.

The technology operates on a thermosiphon principle, where coolant evaporates at hot surfaces and naturally rises due to density differences. The vapor then condenses elsewhere and returns as liquid through gravity, requiring no energy input for the cooling process. “With our two-phase solution, we can remove heat passively without pumps or fans, which significantly reduces the energy consumption for cooling,” says Paw Mortensen, CEO of Heatflow.

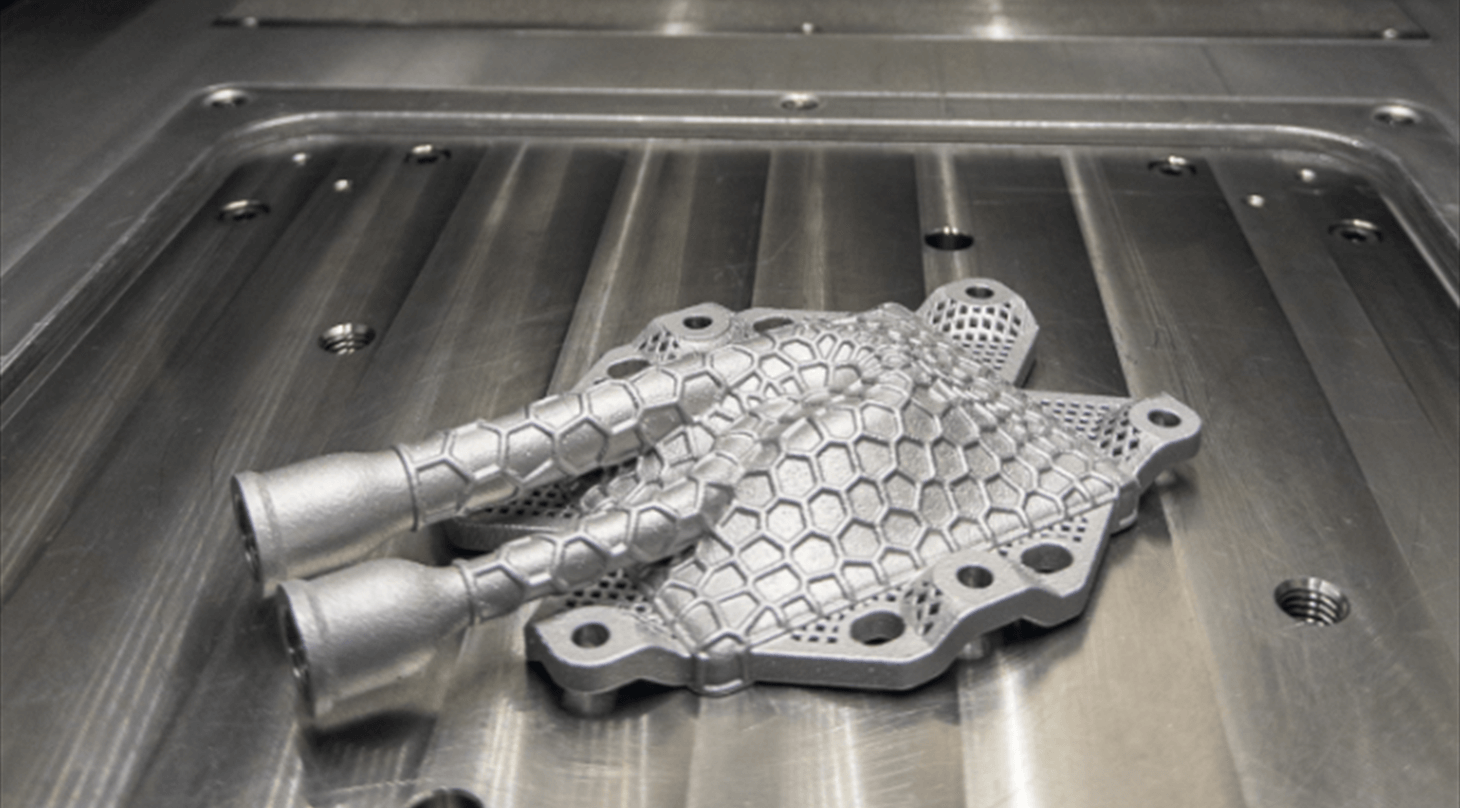

The 3D-printed aluminum evaporator integrates all necessary functions into a single component, reducing assembly points and leak risks. The system removes heat at temperatures between 60 and 80 degrees Celsius, making it suitable for district heating networks or industrial processes. Life cycle analyses indicate the solution could reduce total emissions by 25-30 percent per unit.

The AM2PC project received funding through M-ERA.NET with support from Innovation Fund Denmark, operating on a total budget of DKK 10 million from 2023 to 2025. Partners include Open Engineering from Belgium and Fraunhofer IWU from Germany alongside the Danish organizations.

Source: dti.dk