Disney has recently unveiled a patent furthering its Project Exo initiative, initially introduced in 2021, aimed at bringing larger-than-life characters to its parks. The project, which utilizes a unique exoskeleton technology, has been developed to create lightweight yet massive characters that captivate audiences.

One of the earliest characters brought to life through Project Exo was the Incredible Hulk, making its debut at the 2022 D23 Expo in California. Although the character briefly appeared at Avengers Campus in Disney California Adventure, further applications of the Project Exo technology are yet to be fully realized.

The newly disclosed patent provides an in-depth look at the inner workings of Project Exo, addressing various challenges in creating believable characters on stage. Unlike traditional exoskeleton implementations, which typically augment human abilities, Disney’s Project Exo focuses on creating characters that appear lifelike without the need for superhuman strength.

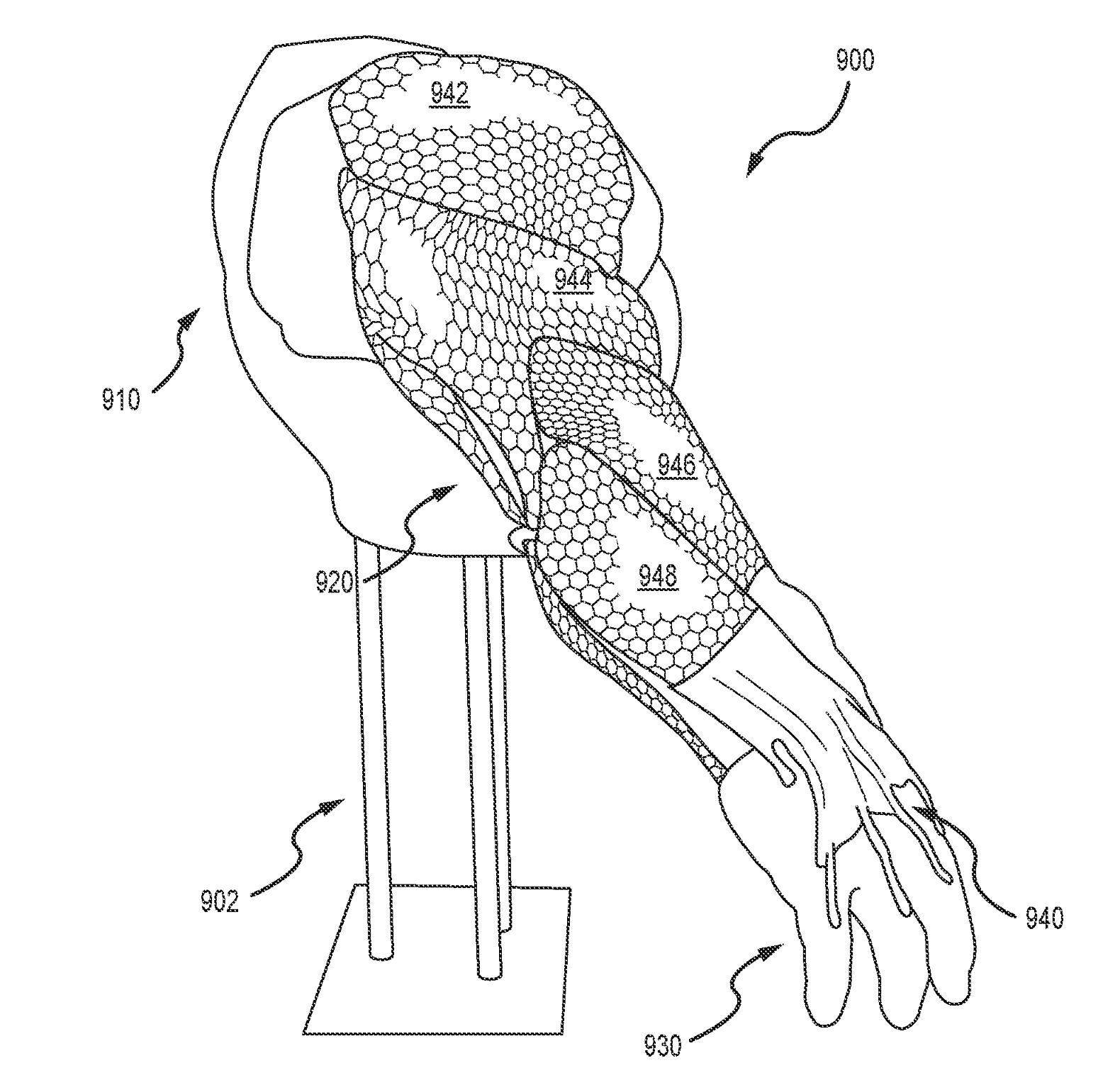

A key aspect of the patent is the introduction of a passive exoskeleton, designed to transfer the weight of the costume away from the performer and into the ground via a unique costume skeleton structure. This innovative approach ensures that characters maintain a realistic appearance while interacting with guests, whether in meet-and-greet environments or parades.

Furthermore, the patent outlines a lightweight lattice structure intended to improve the aesthetics of character costumes. This structure, incorporated into a library of “bio elements,” enables the rapid fabrication of lifelike muscle, fat, and other biological components essential for creating believable characters.

Utilizing 3D printing, these mesh structures can be manufactured on-demand, allowing for the swift production of lightweight and realistic biological elements. This ensures that characters react authentically to external stimuli and movements, enhancing the overall guest experience at theme parks.

Source: blogmickey.com

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.