The Department of Energy (DOE) has awarded $3 million in funding to two companies aiming to decarbonize manufacturing with robust, 3D printed resin tooling.

Resin-manufacturer polySpectra and composite material specialist Fortify, along with National Renewable Energy Laboratory, MPI Systems, RePliForm Inc, and ORNL have been funded to develop direct additive automotive tooling with polySpectra’s Cyclic Olefin Resin-based resins.

“Olefin-based thermoset composites have been used for many decades in extremely demanding applications such as wind turbine blades and fuel cell components, because they are among the most durable materials on the planet,” said Raymond Weitekamp, polySpectra founder.

“Under this research grant, we will leverage Nobel-winning chemistry to directly 3D-print these robust composite Cyclic Olefin Resins. The goal of the DOE project is to bring unprecedented materials durability to additive manufacturing, which will provide the industry with immense leverage for the decarbonization and reshoring of the US manufacturing sector.”

Fortify brings to the table their own DCM (Digital Composite Manufacturing) platform which consists of the Flux printer system (with resin mixers to stop the additives from settling) and also the Flux Developer software. Flux Developer is an open materials platform for the development of viscous and filled resins. It enables users to tailor their own photopolymer composites for printing on the Flux machines.

So what’s that about Nobel Prize chemistry and why is an olefin resin different?

polySpectra has a product named COR Alpha, (the COR stands for Cyclic Olefin) which is a resin that cures into rugged and temperature resistant thermoset plastic when printed on DLP printers. The product was developed from research into olefins undertaken by polySpectra’s founder during his PhD at Caltech.

His PhD supervisor PhD advisor, Bob Grubbs, won the Nobel Prize for his work into olefins in 2005. The COR Alpha material shares its heritage from that research.

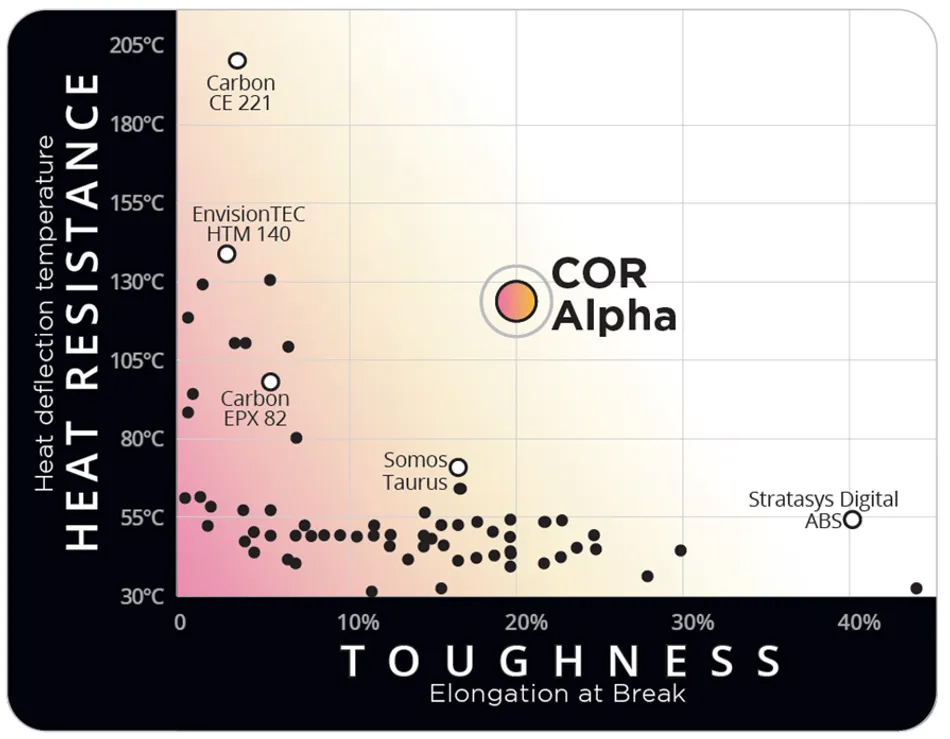

Typical photopolymer resins are not known for being particularly strong, especially when loads are applied during higher temperatures.

COR Alpha, which is manufactured from an olefinic monomer, a ruthenium catalyst, and functional additives, is unique in that it maintains dimensional stability even when heated.

Other thermoplastics and thermoset polymers tend to trade heat resistance for toughness, as you can see in the graph below.

DOE hopes to decarbonize manufacturing, in particular by reducing the time and energy required for CNC machining tooling. Using metal tooling can be seen as overkill, particularly when low production runs are required.

“More than $8B is spent domestically each year on low-volume injection molding. The work addressed by this DOE award will pave the way for printed injection molding to unlock production applications,” said Josh Martin, CEO & Co-founder at Fortify.

“By combining advanced materials and post-processing with lightweight design principles, there is a significant opportunity to make a dent in the time to market, cost, and performance of part production within the automotive industry and beyond.”

The goal of the project is to develop additively manufactured tooling with orders of magnitude improvements on cost and durability versus traditional CNC tooling with cycle times on par with CNC tooling.

And not only will the tooling benefit, but ultimately, new methods of manufacturing with complex, lightweight geometries and tough plastics that can rival metals, will benefit the end product too.

In this case, the focus is on automotive manufacturing where these lightweighting benefits directly translate to energy savings and emissions reduction.

If you’d like to learn more about the COR Alpha resin (now also available in black) then you can head on over to the product page right here.

And if you’d like to know more about starting your own resin material development workflow, then you can check out the Fortify platform over here.