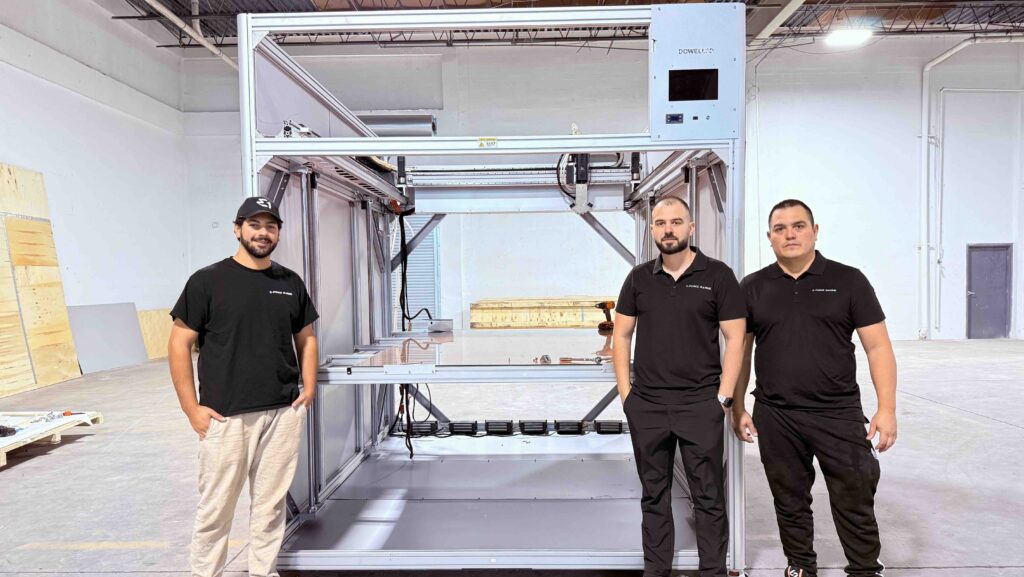

Miami-based E-Force Marine has invested in industrial-scale 3D printing technology to produce hull moulds for its upcoming electric catamaran. The family-owned marine tech firm will demonstrate its progress at the Miami International Boat Show, running February 11-15, 2025.

The company’s approach replaces traditional boat construction methods that require building a full-scale physical “plug” before creating a mould. E-Force Marine’s system digitally designs the hull and 3D prints the mould in approximately 1.5-meter sections, which are then assembled. This method allows for faster design iterations and modifications compared to conventional tooling processes.

“Boatbuilding hasn’t fundamentally changed in decades,” says Al Haghayegh, CEO at E-Force Marine. “For electric vessels, efficiency is everything, and the ability to fine-tune hull performance quickly is a game-changer. Every small gain in efficiency translates directly into more range, better performance, or lower battery requirements, and that level of iteration simply isn’t possible with traditional tooling.”

The catamaran will feature E-Force Marine’s 100kW electric drive system, which has undergone more than three years of testing. Prototype construction is scheduled to begin later this year, with water testing expected within nine months. The company targets a full market launch in 2027.

E-Force Marine first revealed its catamaran designs in 2025 and is transitioning from B2B electric drive systems to developing its own flagship vessel. The company will be located at stand #MB65L during the Miami International Boat Show.

Source: marineindustrynews.co.uk