The EU-funded InShaPe research project has reported significant improvements in laser-based powder bed fusion of metals, achieving a sixfold increase in productivity and reducing production costs by 50%. The three-year project, coordinated by the Technical University of Munich, combined AI-based beam shaping with multispectral imaging to address common issues in metal additive manufacturing. The consortium included eleven partners from eight countries and received €7.2 million in funding from the Horizon Europe framework programme.

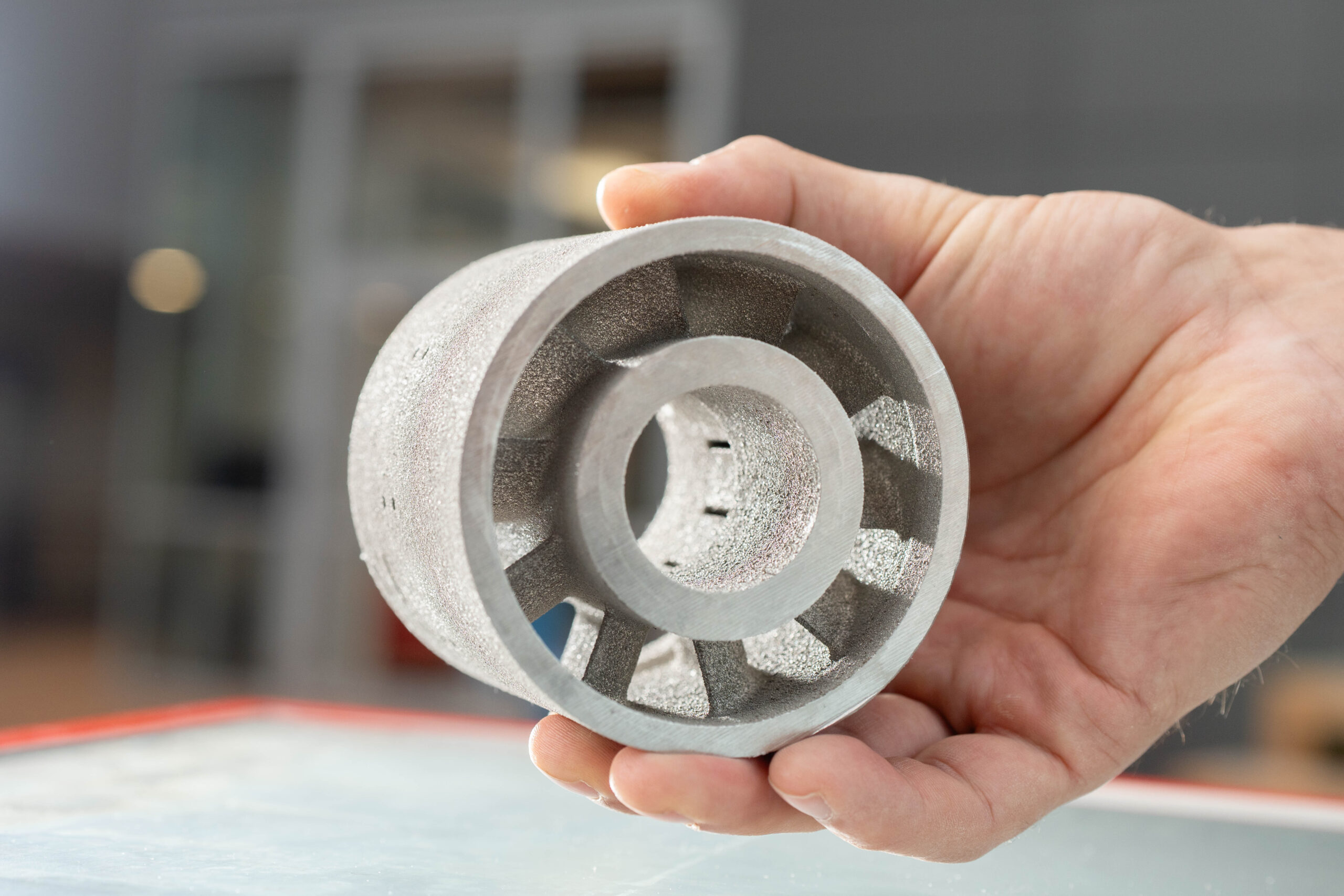

The research team demonstrated manufacturing rates of up to 93.3 cm³/h using Inconel 718, compared to the starting rate of 15 cm³/h. The improvements were tested across five industrial applications, including components for aerospace, energy, and mechanical engineering sectors. These included an aerospace impeller, industrial gas turbine parts, space combustion chamber components, a chainsaw motor cylinder head, and satellite antenna components.

The technology centers on intelligent beam shaping that adapts the laser profile to specific component geometry and materials. Researchers found that a ring-shaped beam profile, rather than a traditional Gaussian beam, created more stable melt zones and improved material processing. This approach reduced common defects such as cracking, spatter, and condensate formation.

The multispectral imaging system monitors the manufacturing process in real-time across various wavelength ranges. This allows for early detection of thermal changes in the melt pool, with data flowing directly into process management systems. Previously production-stopping defects can now be corrected during the process, reducing delays and waste.

“Academic and industrial interest in our work is very high. We are delighted that this technology will soon be used in industrial systems and drive advances in process control, quality assurance and application capabilities across a range of sectors,” commented Prof. Katrin Wudy, the project coordinator from the Technical University of Munich. The project aims to advance the industrial adoption of laser-based powder bed fusion technology, particularly in aerospace, energy, and automotive applications.

Source: bayfor.org