A group of researchers from Budapest, Hungary have developed a novel means of 3D printing objects made from a combination of nano-/microfibers and solid or infill layers.

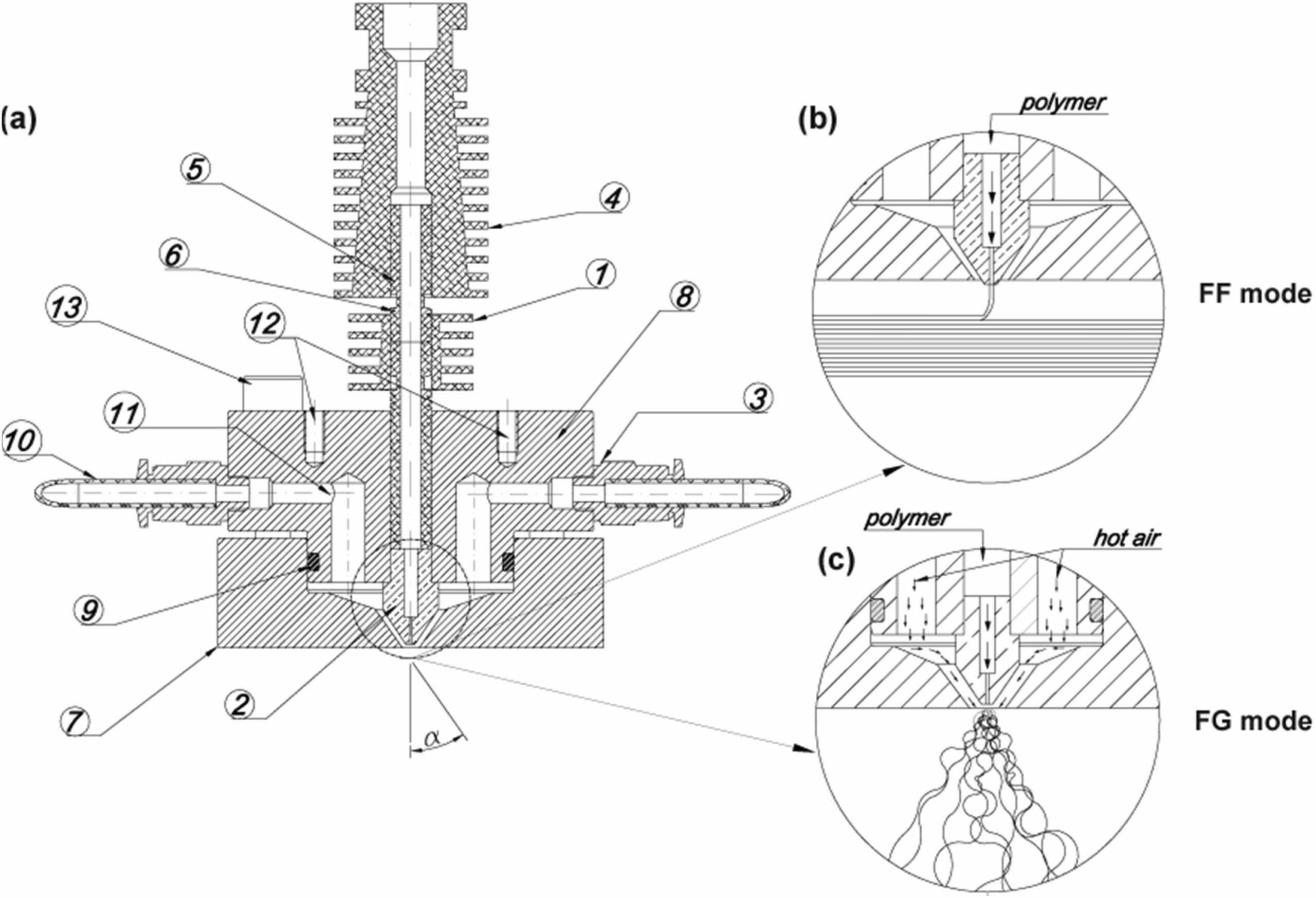

The method is a unique combination of material extrusion and melt-blowing, and has been enabled by the development of a special printhead.

Melt-blowing

As mentioned in the intro, the new method is a combination of polymer extrusion (FFF) and melt-blowing.

In melt-blowing, a jet of hot air is passed around a mass of molten plastic, resulting in thin, hair-like filaments being blown away from the mass of molten plastic, where it solidifies into strands. Using this method, the researchers were able to make strands measuring as little as 300 nm.

You can see the experimental setup in the image below. A Velleman 8200 FFF printer was used as the main system and with the supersonic hot air jet was fitted to the system on the end of an off-the-shelf hotend.

You may have not heard of melt-blowing before, but if you have been on planet Earth since late-2019, there’s a good chance that you have been in contact with objects manufactured with the melt-blowing process. That’s right, surgical masks and other filtration systems are often made with a melt-blowing process.

When making filtration masks, the tiny melt-blown fibers are blown onto a shaped substrate to form non-woven textiles. The random pattern formed by the cooled fivers forms a tortuous path which serves as a filter, trapping particles within the fiber matrix.

The new printing method allows both FFF-type deposition, or FG (fiber generation) modes for production of traditional AM solids and/or fibers mats, respectively.

The researchers, hailing from the MTA-BME Lendület Lightweight Polymer Composites Research Group and Budapest University of Technology and Economics utilized CFD for simulating the supersonic airflow fields to help determine the optimum parameters for the process.

Combined Modes

By use of the process the team used PLA plastic for both FFF-mode and FG-mode. They were able to print a typical FFF-layered type solid substrate and then jet the melt-blown fibers onto the substrate.

The blown fiber layers were also found to enhance the crystallinity of the printed products, and had a reinforcing effect on the printed substrate.

The team were able to control the position and ratio of the fibers and also the solid (or infilled) parts of the printed object, so porous objects could also be fabricated.

The researchers say in their paper that hierarchical 3D printed objects manufactured with this hybrid method have potential applications as scaffolds, smart nonwoven textiles, controlled drug delivery devices, filter media (such as masks), and structural composites.

You can read the researchers’ paper, titled “A novel method and printhead for 3D printing combined nano-/microfiber solid structures” in the Additive Manufacturing journal, over at this link.