XTPL S.A. is at the forefront of additive manufacturing with its Ultra Precise Dispensing (UPD) technology. This innovative method significantly advances the precision fabrication of micro and nano-scale structures, crucial for the next generation of display manufacturing. In this article, we will explore the specifics of UPD technology and examine its various applications in detail.

Advancing Display Technology with XTPL’s Ultra Precise Dispensing

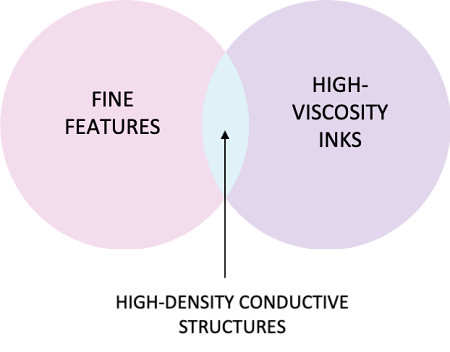

At the core of XTPL’s Ultra Precise Dispensing (UPD) technology is its sophisticated ability to dispense ultra-fine lines of nanomaterials with exceptional accuracy, utilizing a proprietary printing head designed for precise control. This allows for line widths much narrower than traditional printing methods, essential for creating detailed circuitry in high-resolution displays. XTPL’s technology also excels in printing materials of high viscosity and creating high aspect ratios in a single pass, supporting a variety of materials and complex topographies on virtually any substrate.

Key technological properties are:

- – ability to print high viscous materials along with small feature sizes,

- – high aspect ratios just after a single pass,

- – matchless variety of printing different materials,

- – uninterrupted interconnections on highly complex topographies,

- – ultra-high-resolution printing on practically any kind of substrate.

Material Innovation: Tailored Solutions

XTPL has developed specialized formulations of inks and pastes to match the unique demands of various nanomaterials, ensuring smooth flow and precise deposition. These materials are crucial for building consistent and reliable microstructures on different substrates and are versatile enough for both conductive and non-conductive applications across various sectors of display manufacturing.

For further details on this technology, we recommend exploring this article.

Precision Engineering: Enhanced Control and Efficiency

The UPD system is designed for precision, incorporating features like real-time monitoring and adjustments during the dispensing process. This precision is critical in large-scale production settings where consistency is key. Moreover, efficient material usage not only reduces waste but also cuts costs, contributing to more sustainable manufacturing practices.

Customization and Scalability: Adapting to Industry Needs

One of XTPL’s strengths is the adaptability of its UPD technology, with customizable printing heads that cater to a wide range of applications, from traditional display manufacturing to emerging fields like biosensors and photovoltaics. This scalability makes it suitable for both experimental R&D and full-scale commercial production.

Technological Impact: Pioneering Future Developments

By integrating UPD technology, XTPL not only improves the quality and resolution of displays but also enhances the efficiency and precision of the manufacturing process. This approach not only addresses current industry needs but also sets the stage for future advancements in display technology and other high-tech areas, pushing the limits of what additive manufacturing can achieve.

Display Manufacturing with XTPL’s UPD Technology

XTPL’s Ultra Precise Dispensing (UPD) technology is enhancing the display manufacturing industry by enabling higher levels of precision and flexibility in the production of high-resolution screens. This section delves into the applications and effects of UPD technology within display manufacturing.

Elevating Precision in Display Production

XTPL’s Ultra Precise Dispensing (UPD) technology is transforming the display manufacturing industry by enabling the production of high-resolution screens with unprecedented precision. This technology allows for the accurate placement of nanomaterials, essential for creating high-definition pixel arrays in modern displays like OLEDs and flexible screens. Such precision is vital for minimizing pixel defects, ensuring optimal clarity and visual consistency in the final product.

Seamless Integration with Production Lines

The UPD system from XTPL can be seamlessly integrated into existing manufacturing lines, allowing display producers to enhance their capabilities without extensive modifications. This adaptability makes the UPD system a versatile tool, compatible with various substrates and screen sizes, from compact mobile displays to expansive television panels.

Enhancing Material Efficiency and Production Speed

XTPL’s technology significantly reduces material waste by precisely dispensing materials only where needed, contrasting with traditional methods that often require subsequent etching. This precision not only conserves materials but also speeds up the production process by eliminating the need for certain post-processing steps. Faster production times enable manufacturers to more quickly meet the increasing consumer demand for advanced displays.

Customization for Innovative Display Designs

UPD technology excels in producing specialized displays that require unique configurations, such as curved or irregular shapes. This capability is particularly beneficial in sectors like automotive and healthcare, where customized display solutions can enhance both functionality and aesthetics.

Future-Ready Applications

As the industry continues to evolve toward higher resolutions and more complex configurations, XTPL’s UPD technology stands ready to meet these future demands. Its ability to create finer lines and detailed microstructures ensures that manufacturers can keep pace with rapid advancements in display technology and evolving consumer expectations.

Final Thoughts

As XTPL’s Ultra Precise Dispensing (UPD) technology redefines the landscape of display manufacturing, its profound impact on enhancing precision and reducing waste underscores a pivotal shift towards more sustainable and efficient production methods. By enabling the creation of highly detailed and complex structures essential for the next-generation displays, XTPL is not only meeting today’s technological demands but also paving the way for future innovations in the industry, ensuring readiness for evolving market needs and new technological challenges.