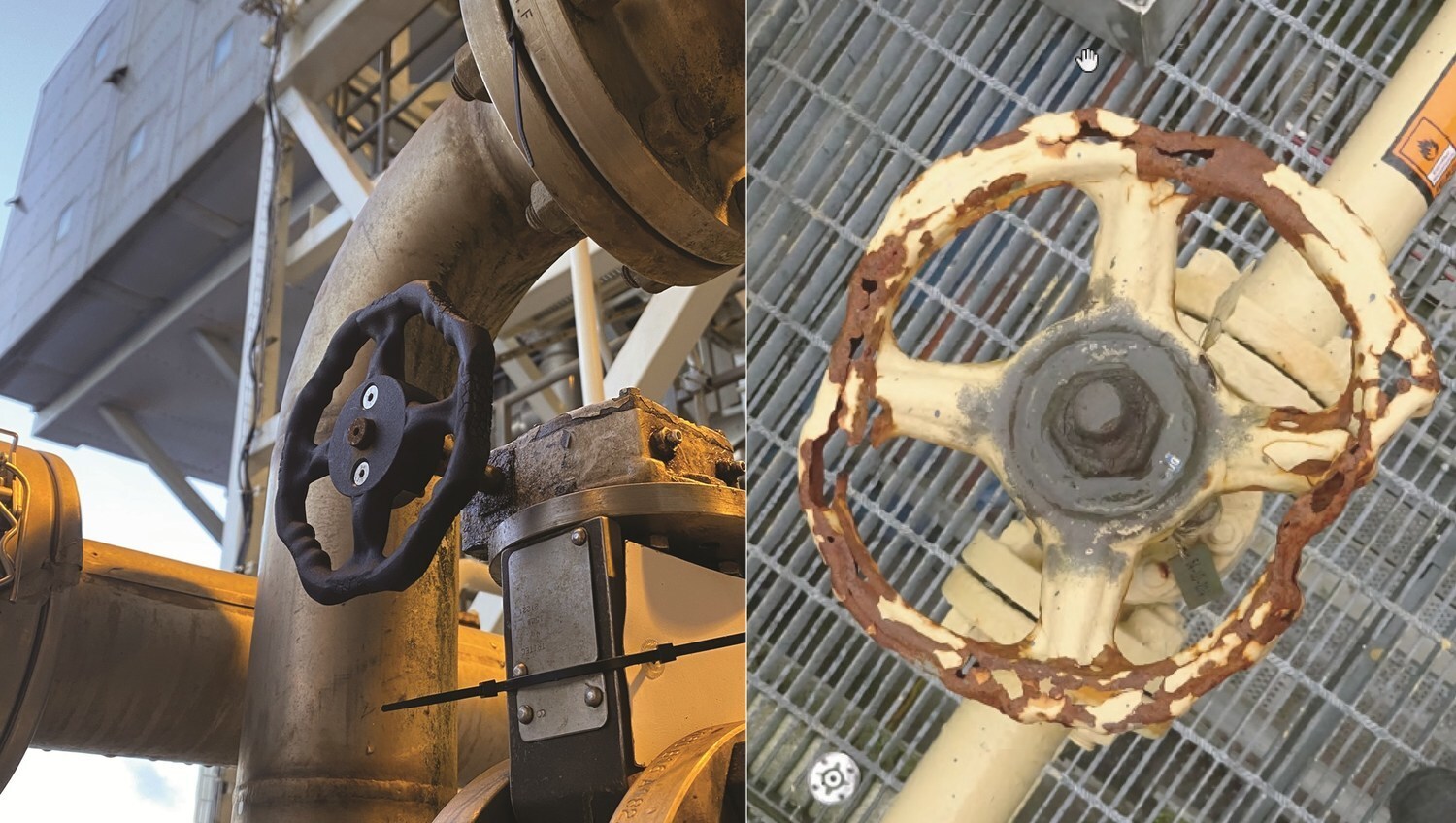

Assembrix Ltd., HP, Sparely, and Korall Engineering AS have completed a series of secure remote additive manufacturing operations across multiple global sites to produce certified spare parts for the oil and gas industry. The collaboration produced polymer valve handwheels designed for manual operation of non-critical valves on ships and offshore platforms. Parts were printed at several HP partner sites using HP Multi Jet Fusion systems integrated with the Assembrix software platform.

The printed components were made from HP 3D High Reusability PA12 materials, which Korall Engineering is qualifying in collaboration with DNV. These represent the first additive manufacturing polymers to be qualified for offshore applications. The resulting designs offer corrosion resistance and durability in harsh environments while reducing material use, weight, and production lead times.

Each build process was encrypted, remotely managed, and monitored in real time to validate repeatability, traceability, and security. The Assembrix platform provides encryption and control for every stage of printing production to protect sensitive build files. “The series demonstrated that identical parts can be produced across regions without compromising integrity, proving that secure, scalable distributed manufacturing is now an industrial reality,” stated Lior Polak, CEO of Assembrix.

The approach aims to reduce lead times from months to days while cutting logistics costs and inventory requirements for oil and gas operators. Localized production also reduces transport emissions and material waste compared to traditional manufacturing methods. “This collaboration proves that secure digital manufacturing can be both scalable and practical for the oil and gas sector,” commented Bernhard van Riessen, CEO of Sparely.

The partners position this work as establishing a benchmark for connecting design, certification, and production in a secure global network. “By combining Assembrix’s secure digital workflow, HP’s production consistency, Sparely’s global production network, and our qualified family of specialized designs, we demonstrated that essential components can now be produced safely and locally, ready for certified field use,” said Bruno Maffei, CEO of Korall Engineering.