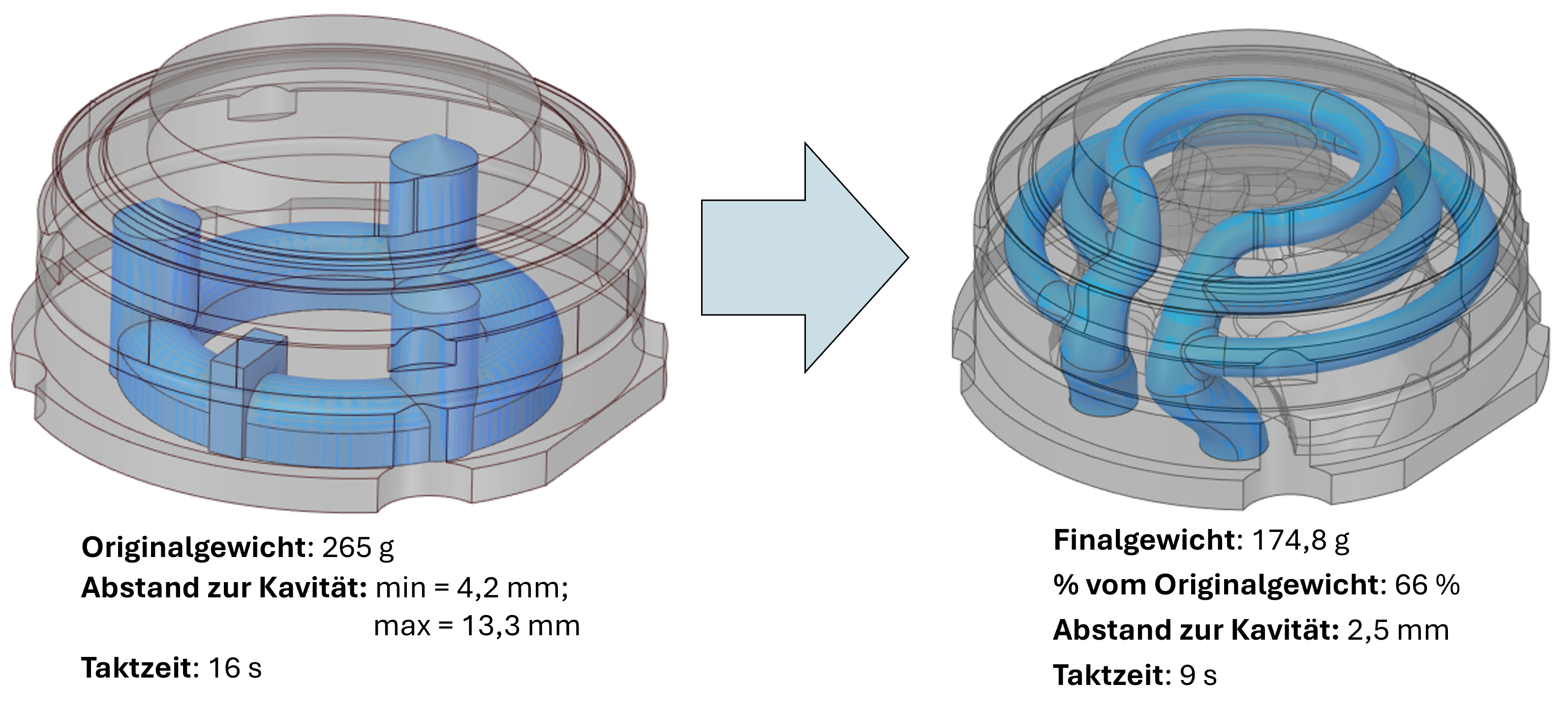

A German research project has demonstrated that 3D printed manufacturing tools can achieve weight reductions of around 30% compared to conventional designs. The AdTopoTool project, led by Fraunhofer IWU alongside industrial partners Werkzeugbau Winkelmühle GmbH and H+E Produktentwicklung GmbH, used topology optimization and enhanced cooling channel designs to create lighter tools without sacrificing structural integrity.

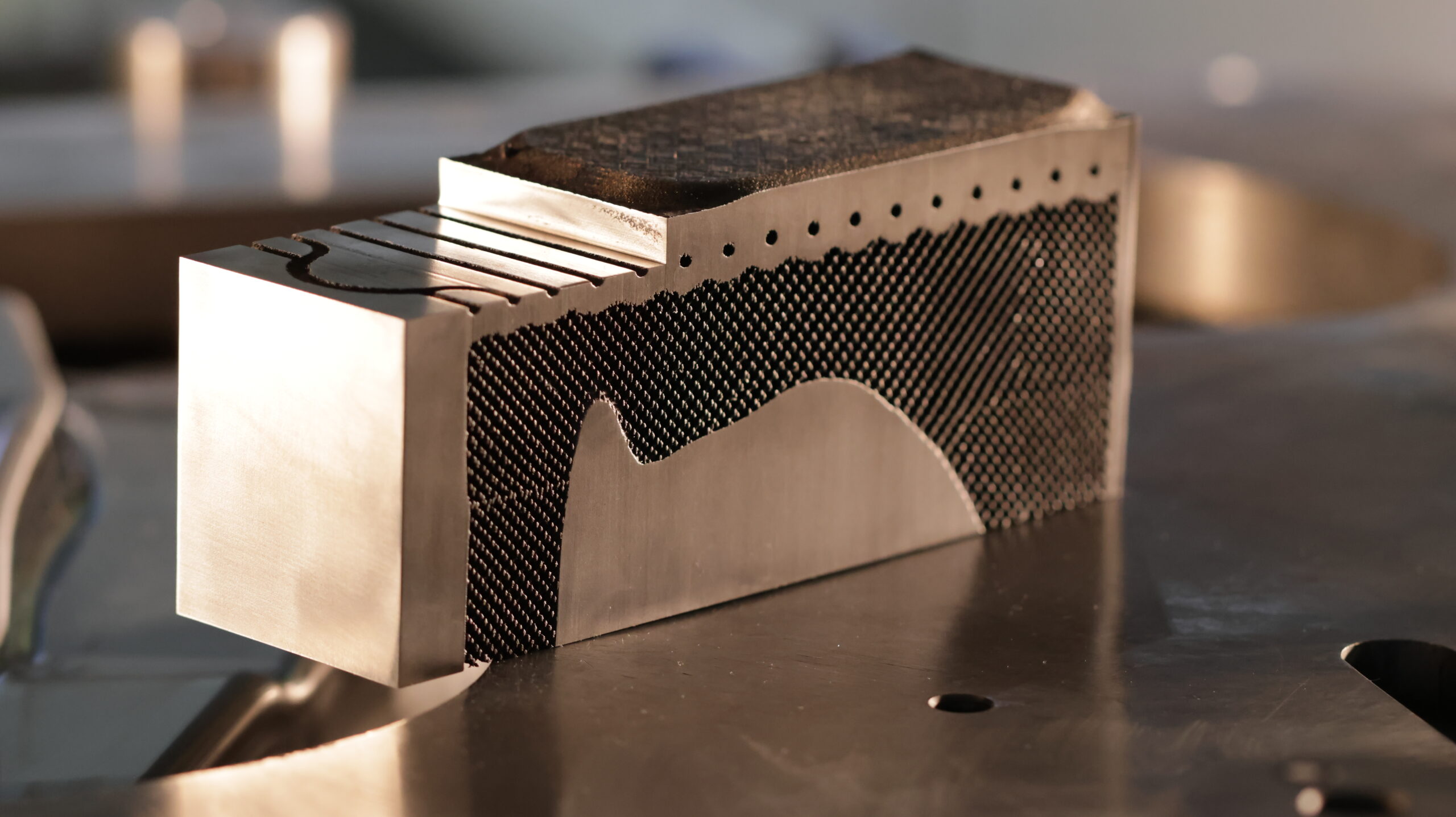

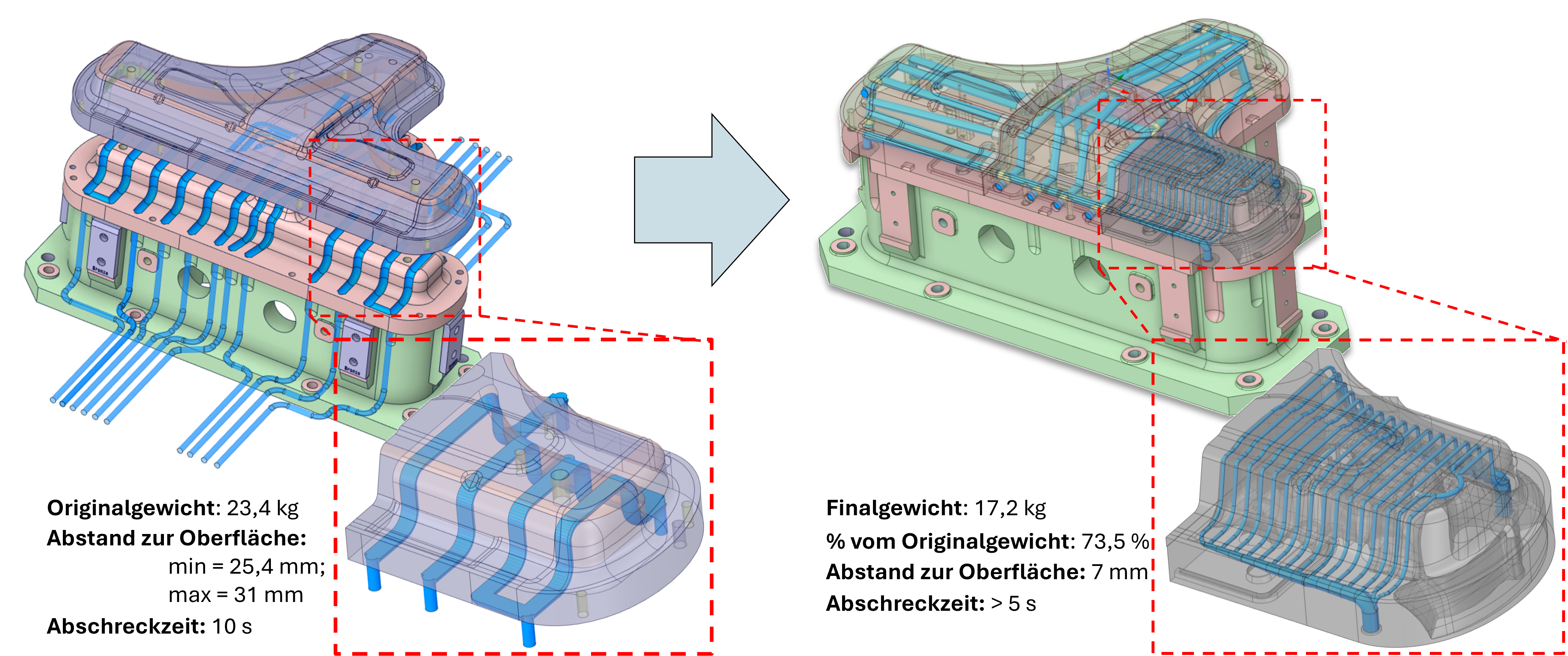

The research team developed numerical methods to predict how thermally stressed tools behave under operating conditions. They applied these methods to create optimized tool geometries for injection molding and press hardening applications. Testing showed a 34% weight reduction for injection molding tools and 28% for press hardening tool segments while maintaining form stability.

Beyond weight savings, the improved cooling systems delivered notable performance gains. Cycle times for injection-molded components were reduced by 60%, while heat treatment times for press-hardened components were nearly cut in half. The researchers also reported improvements in component quality and dimensional accuracy in some cases.

Fraunhofer IWU is now working on a follow-up project called EWAM (Efficient Toolmaking with Additive Manufacturing) to address adoption barriers. The project aims to develop automated software tools that can design temperature control systems for 3D printed manufacturing tools. The planned software plug-in will be compatible with various 3D CAD programs and use universal programming languages to facilitate industry adoption.

The research combines laser powder bed fusion 3D printing with optimized geometries and intelligent cooling systems. Fraunhofer IWU expects this approach to benefit medium-sized tool manufacturers by providing faster implementation and more resource-efficient solutions.

Source: iwu.fraunhofer.de