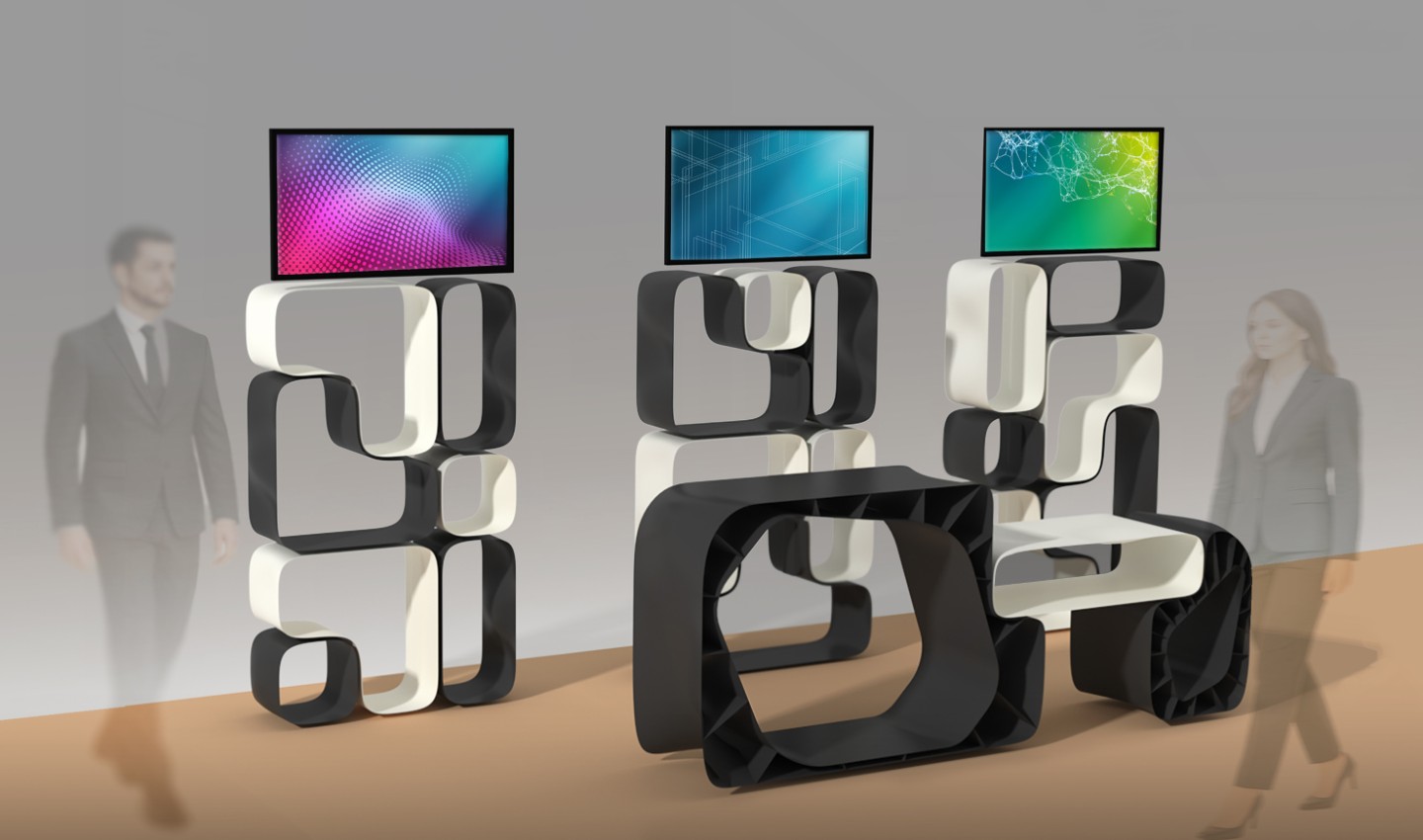

Fraunhofer IWU will present advances in laser powder bed fusion technology and sustainable exhibition design at Formnext 2025 in Frankfurt, November 18-21. The research institute’s booth will feature a fully 3D-printed structure made from biodegradable plastic and recyclable polypropylene, which will be reassembled and reused after the event.

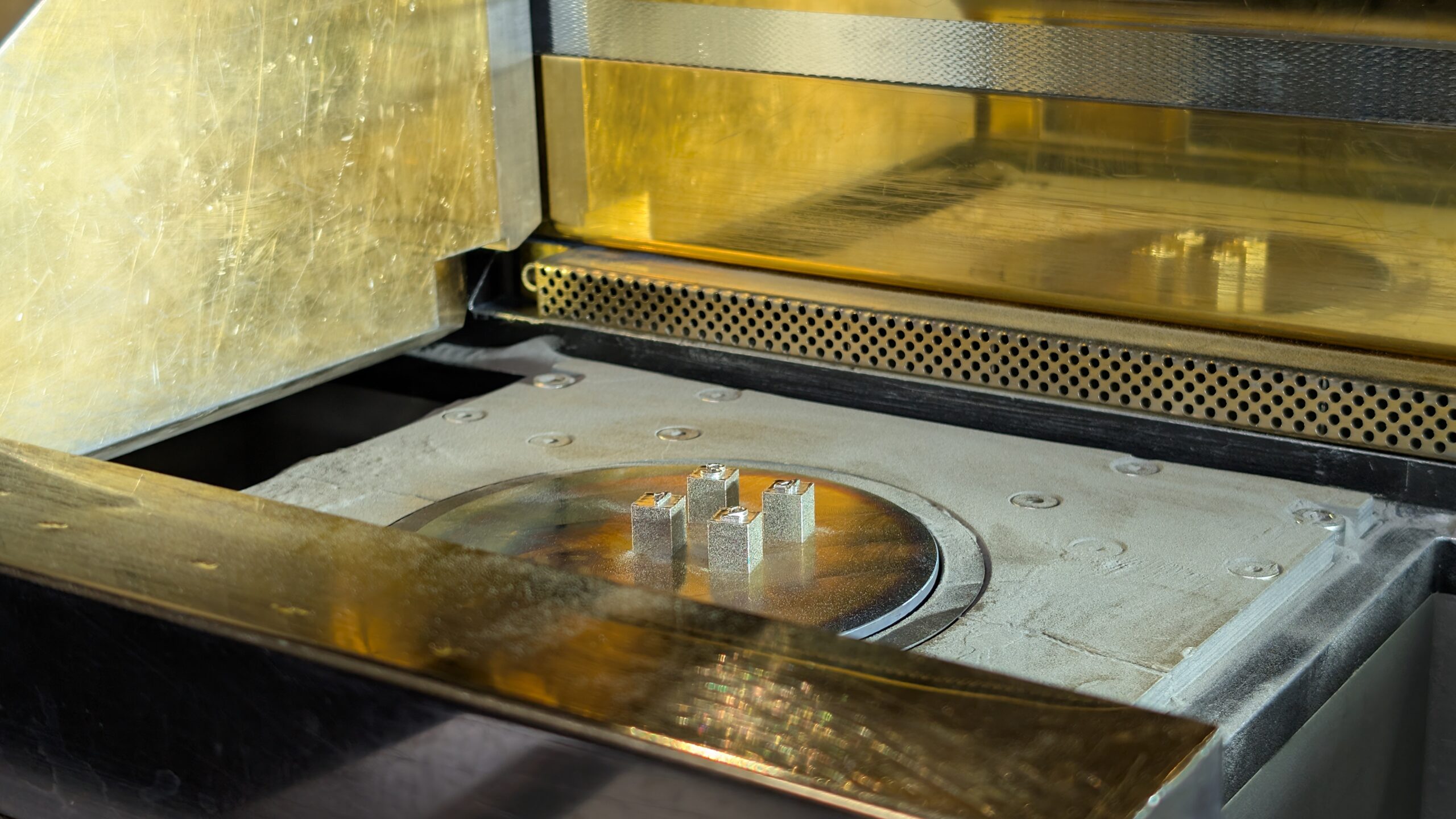

The organization’s Dresden branch has acquired a high-temperature LPBF system capable of preheating powder beds to temperatures up to 1,200°C. This technology enables processing of refractory metals like tungsten and titanium aluminide, materials previously limited to electron beam melting processes. The system allows for higher resolution printing of thin-walled structures with precise microstructure control.

Fraunhofer’s materials research focuses on aerospace applications, including aluminum matrix composites reinforced with silicon carbide particles for improved wear resistance. The team is also developing processing strategies for Constellium Aheadd® HT2, a heat-resistant aluminum alloy designed to withstand operating temperatures of 250-300°C in aerospace applications.

The exhibition booth demonstrates large-scale 3D printing capabilities, with three shelving units and a counter produced using only 55 kg of recycled carbon fiber-reinforced polypropylene granulate. Manufacturing time totaled just under 13 hours, and the modular system could be commercially produced for approximately €1,500. The lightweight sandwich construction provides high load-bearing capacity while remaining space-efficient for transport.

Fraunhofer will also showcase the WEAM process for integrating electrical functions directly into 3D-printed components.

Source: iwu.fraunhofer.de