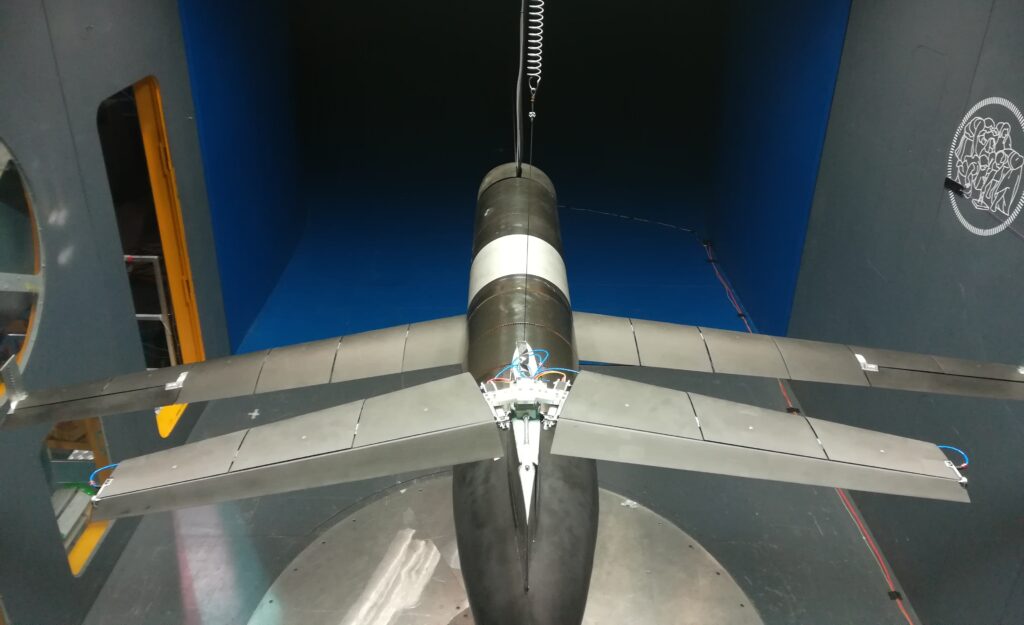

CRP technology just developed parts for aeroelastic wind tunnel demonstrators in collaboration with Department of Aerospace Science and Technology of the Politecnico di Milano (PoliMi). As part of the Aeroelastic Flutter Suppression (AFS) and GLAMOUR Projects, they heavily utilized SLS 3D printing. Both projects required highly technical aerospace components, showcasing the efficiency of CRP’s 3D printing expertise.

As a demonstrative tool, the companies developed a representation of a real aircraft wing tip section. It needed to function like the real thing while being significantly cheaper and malleable. The end purpose of the aerodynamic parts was correct and enhance the external shape of the wing, while simultaneously transferring the aerodynamic loads to the internal structure.

As a result, CRP developed the external aerodynamic segments of the two wind tunnel demonstrators for both projects using SLS and and carbon-composite Windform XT 2.0 and, from its range of composite materials for LS, the Windform TOP-LINE. They also applied Windform XT 2.0 for horizontal tail of the wind tunnel demonstrator for the AFS project.

Both projects have distinct purposes and exist to conduct various technical tests. The AFS project, under PoliMi and the University of Washington, tests different active control system technologies aiming to attain Active Flutter Suppression. Similarly, the GLAMOUR project focuses on technological optimisation and experimental validation of Gust Load Alleviation (GLA) control systems for an advanced Green Regional Aircraft for the Leonardo Aircraft Division.

Printing Wind-Tunnel & Aerospace Components

Although 3D printing aerospace parts is common now, SLS was a change of pace for the manufacturing process. Previously, the sections of wings were the result of carbon or glass fibre fabrics dry lamination. This method utilised wrapped Styrofoam blocks cut to match the wing’s shape. As one may imagine, such a process took longer, so SLS is a step up. Even aside from the time consumption, the process resulted in low quality surface finishes. This changed with AFS and the GLAMOUR project.

CRP and PoliMi had a tough task, balancing parts that were lightweight yet stiff with thin layers. Since the parts are subjected to intense wind conditions, their surface finish is crucial to their aerodynamic capabilities.

For the AFS project, Windform XT 2.0 composite material and laser sintering allowed for unique wing sections designs. This came down to the connections to the main spar and the hinges and the electric drivers. Similarly, the GLAMOUR project also used Windform XT 2.0 allowing the combination of the vibration frequency targets together with the forced mass constraints.

Featured image courtesy of GLAMOUR and AFS Projects.