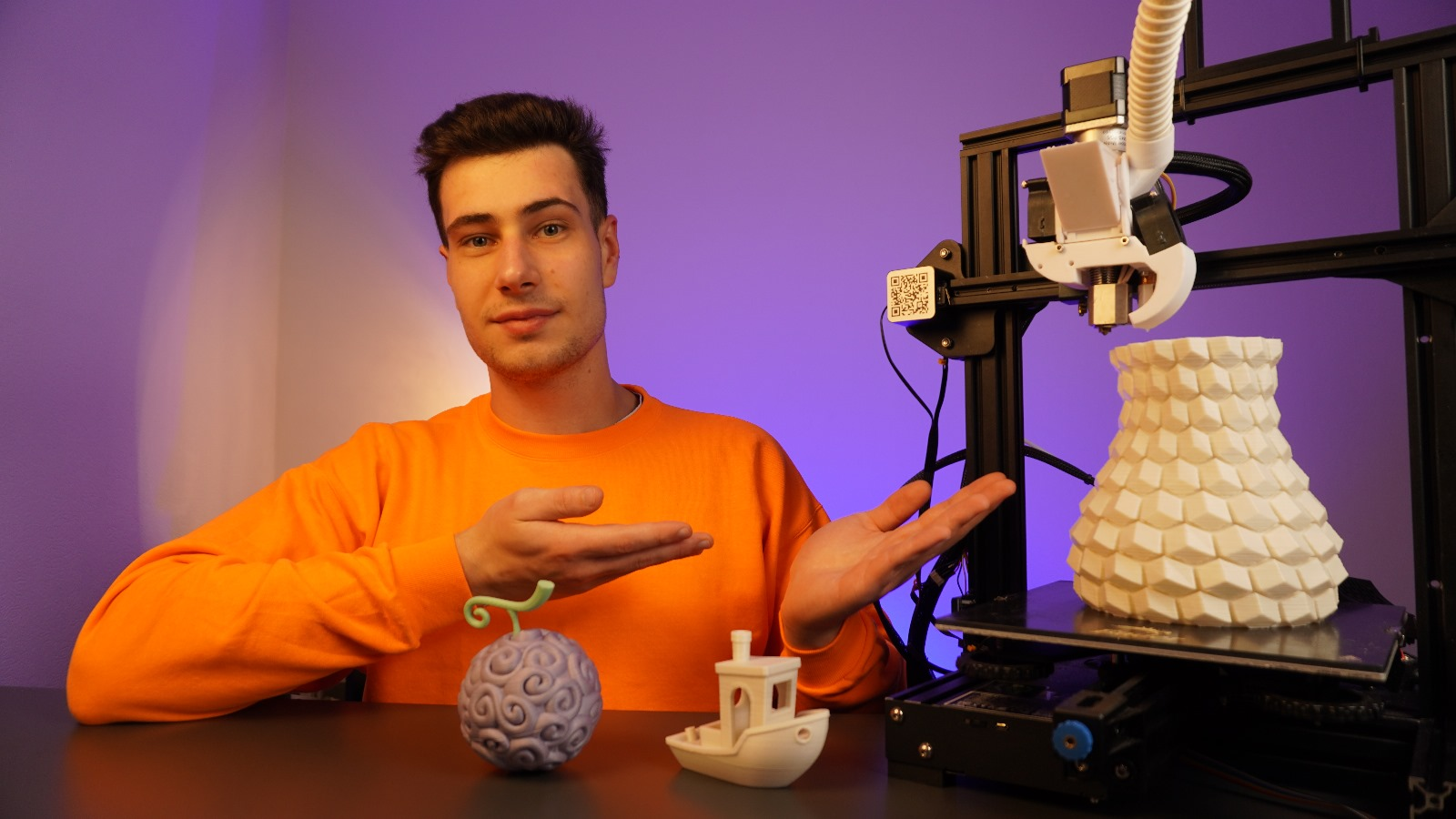

3D printing fan and YouTuber Kristian Friesen, widely known as “GreenBoy3D,” is spearheading the development of a low-cost pellet extruder, challenging the conventional filament-based FFF 3D printing paradigm. Unlike traditional filament, which adds a substantial overhead cost to the process, pellets offer a significantly more economical alternative. Friesen’s innovative approach not only seeks to slash costs but also aims to streamline operational efficiency.

The crux of Friesen’s design lies in its gravity-fed mechanism, a stark departure from conventional pneumatic delivery systems utilized by larger commercial counterparts. While these commercial systems boast impressive material capacities, often exceeding the needs of desktop printers, Friesen’s focus on efficiency and cost-effectiveness is evident in his gravity-fed design. By prioritizing functionality over volume, Friesen ensures that his pellet extruder is not only cost-effective but also easily adaptable to existing FFF 3D printer platforms.

Moreover, Friesen’s design addresses several operational challenges inherent in filament-based printing, offering seamless material changes and potential recycling opportunities. By simplifying the printing process and leveraging the cost advantages of pellets, the GreenBoy3D Pellet Extruder holds the promise of democratizing 3D printing, making it more accessible and affordable to a broader audience.

While the exact release date and pricing details remain uncertain, the potential impact of Friesen’s innovation on the 3D printing industry cannot be overstated. By paving the way for a transition from filaments to pellets, this project represents a significant step towards a more sustainable and cost-effective future for additive manufacturing. With ongoing feedback and refinement, Friesen’s endeavor is poised to revolutionize the way we approach 3D printing.

Source: fabbaloo.com

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.