Printing metals with LPBF methods leaves a rough finish, which requires costly post processing. Sure, you can throw the part onto a CNC mill, and smooth everything on the exterior surfaces, but it’s time consuming, and what about the interior surfaces and other faces inaccessible to the cutting tool?

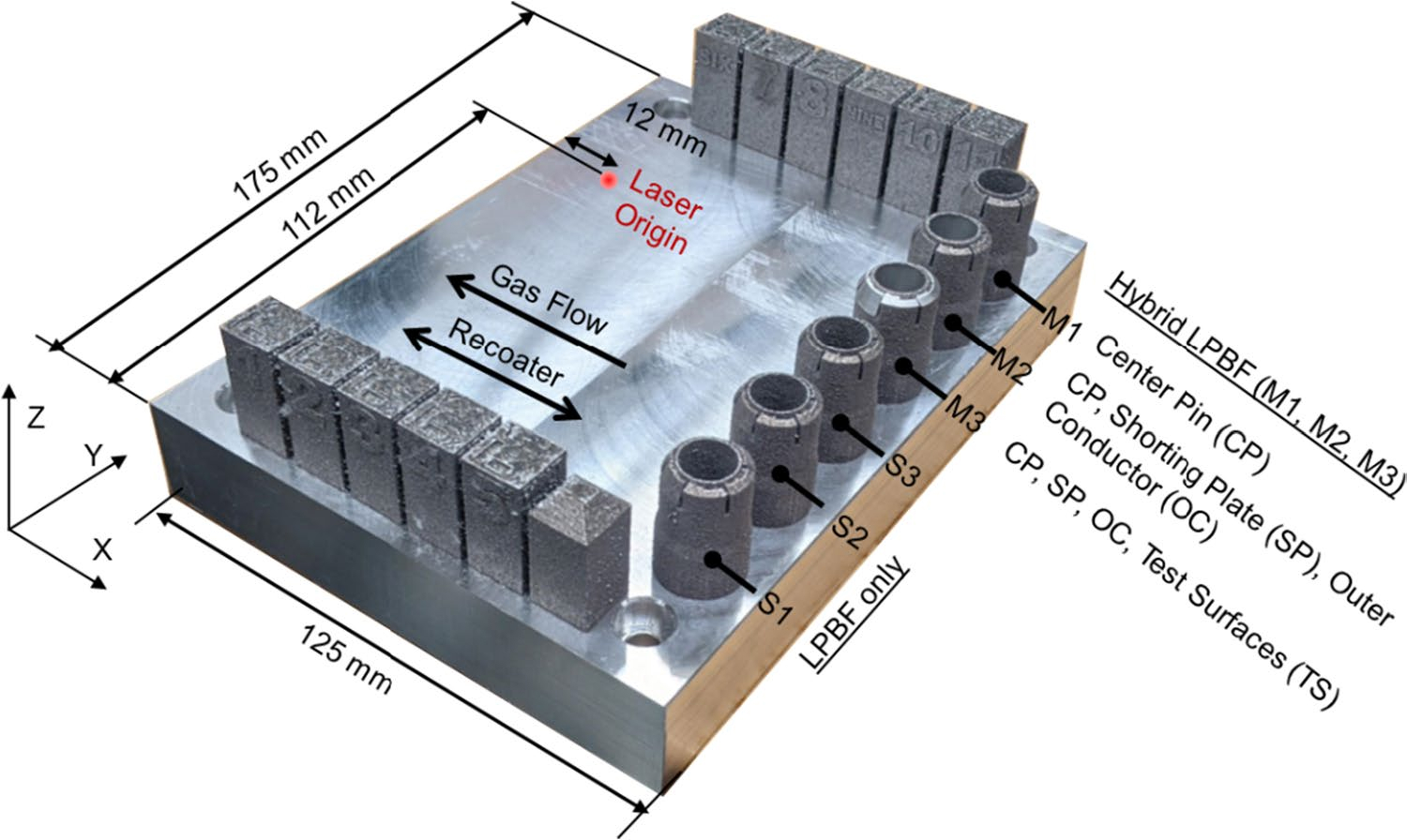

Researchers from University of Nebraska-Lincoln and Virginia Tech have found a solution with a hybrid additive/subtractive approach (h-PBLF), and they have demonstrated the results by printing a bunch of quarter wave resonators (QWR) to show it.

Read on for more information.

Hybrid Approach

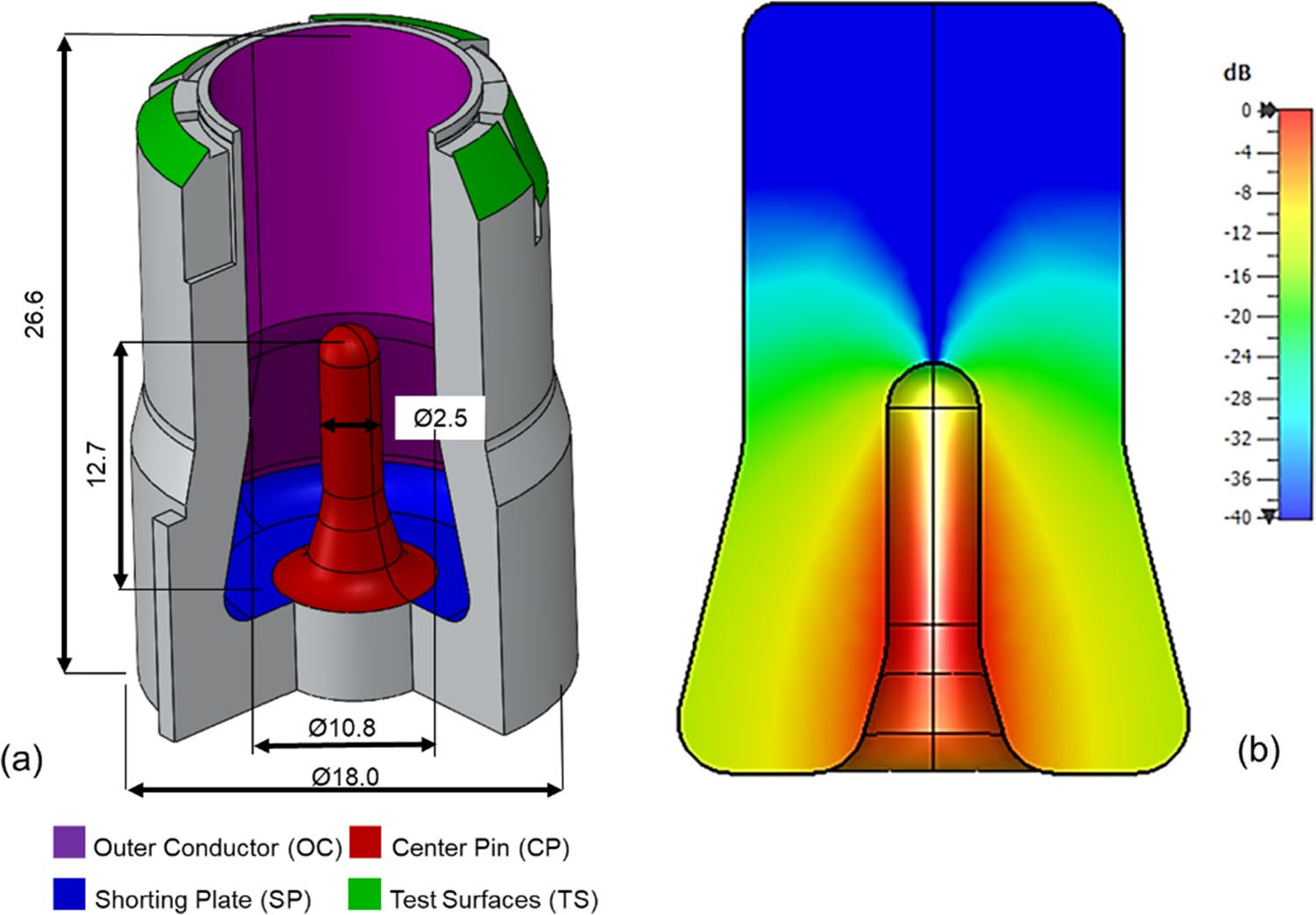

CNC post processing of metal printed parts is no problem really. But when smoothing parts beyond the reach of a CNC toolhead, the tool just can’t get in there. You can see the internal geometry of the QWRs below.

There have been alternative methods (superfinishing), normally using means such as magnetic rheological finishing, chemical machining or abrasive flow finishing but these processes have a slow material removal rate, and the results are often not as predictable as when using a CNC.

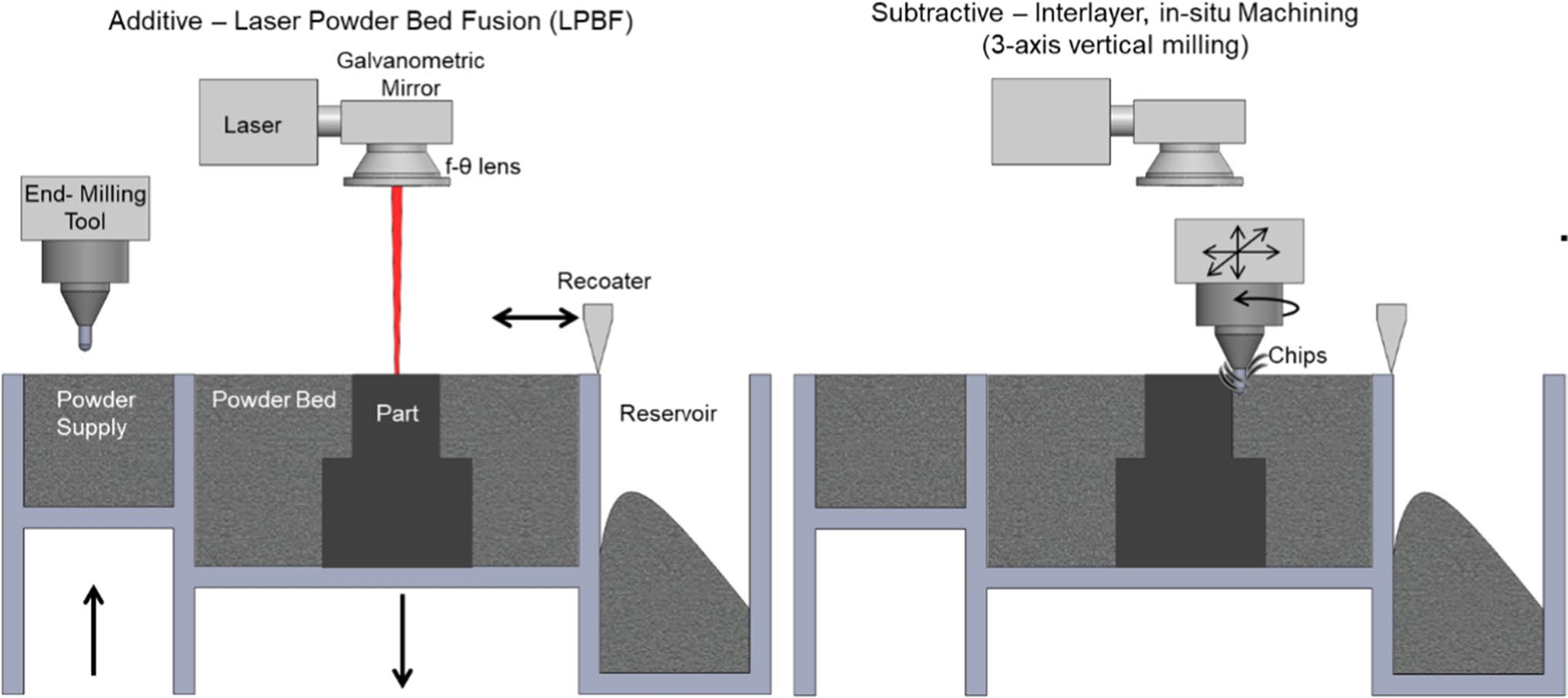

The approach from the researchers relies on printing just a few layers at a time, and then machining only the sides with a ball end mill on a 3-axis CNC vertical milling machine, rather than machining the tops of the printed layers.

They effectively print, then smooth the side walls of that printed section, in sections of around 10 layers (totalling 5 mm in height). This means they can smooth features beneath overhangs etc before printing the overhang (or other obstructing feature) is actually formed. Smart!

The diagram below highlights the approach, which combines the LPBF system and 3-axis CNC vertical milling machine in one unit, for in-situ hybrid manufacturing.

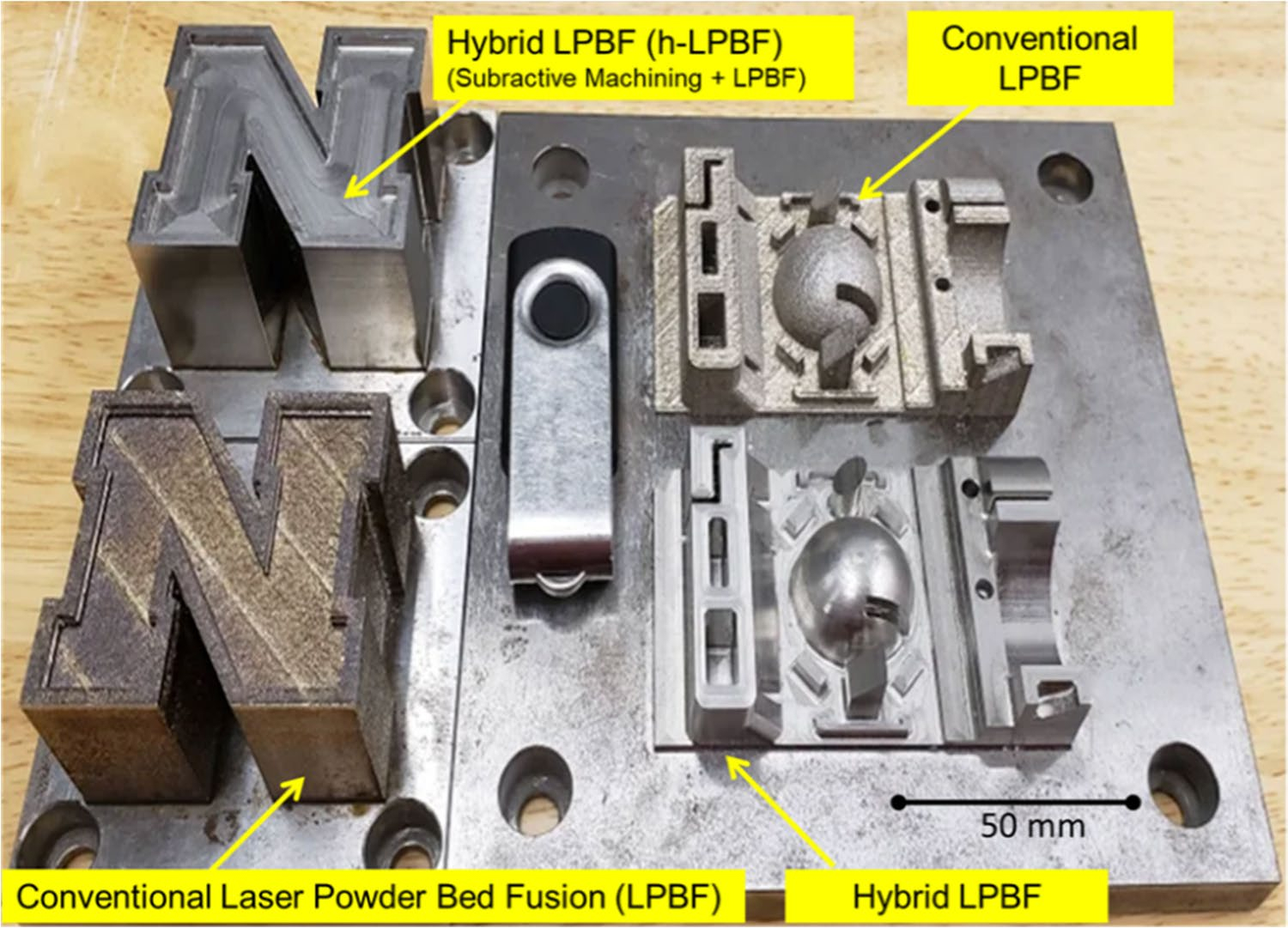

This experiment was the first time that this hybrid approach has been used to manufacture a quarter wave resonator using a hybrid additive-subtractive laser powder bed fusion approach.

A quarter wave resonator (QWR) is a passive radio frequency component with fairly complex internal geometry. By using the hybrid approach, they were able to obtain surface finishes of Ra~2 μm compared to around Ra~8 to 20 μm for the conventional LPBF method on its own.

You can see the difference with your very own eyes in the image below.

The CNC section had an automatic tool changer capable of holding 40 different cutting tools. A ball end mill of 2mm diameter was used with a spindle speed of almost 30,000 RPM, and a feed rate of 1500 mm per minute. The material was removed in multiple passes during the milling stage, including roughing, semi-finishing, and finishing passes.

Matching the Powder Size

These parameters were deliberately selected, as they resulted in around 50 μm of material removed per revolution of the cutting tool. This means that the chips were approximately the same size as the powder feedstock, and therefore there were no issues with depositing the subsequent printed layers after the smoothing had been completed on that section.

The high speed and low chip load of the machining stage ensured a surface roughness in the micrometer range and allowed the processing of delicate features.

The improvement in surface finish resulted in reduced RF losses by a factor of almost 2. Consequently, the RF performance (Q-factor) of the hybrid manufactured QWR components were 1.5 to 2 times superior compared to parts made with the usual LPBF method.

You can read more about the research in the paper titled “Application of hybrid laser powder bed fusion additive manufacturing to microwave radio frequency quarter wave cavity resonators” at this link.