A new hybrid printing process developed by researchers at the University of Amsterdam (UvA) is promising to speed up printing of resins at sub-micron levels.

The process has been developed by Dr Suhas Nawada, who previously worked as a post-doctoral researcher at the Van ‘t Hoff Institute for Molecular Sciences at UvA.

The method combines elements of both SLA and DLP printing, with the rapid low resolution work being done by the DLP and the slower high resolution aspects being performed by the SLA segment, thus allowing both high speed and high resolution.

The technology has been licenced to Gouda-based company atum3D via the Amsterdam Innovation Exchange (IXA), which is UvA’s technology transfer office.

Best of Both Worlds

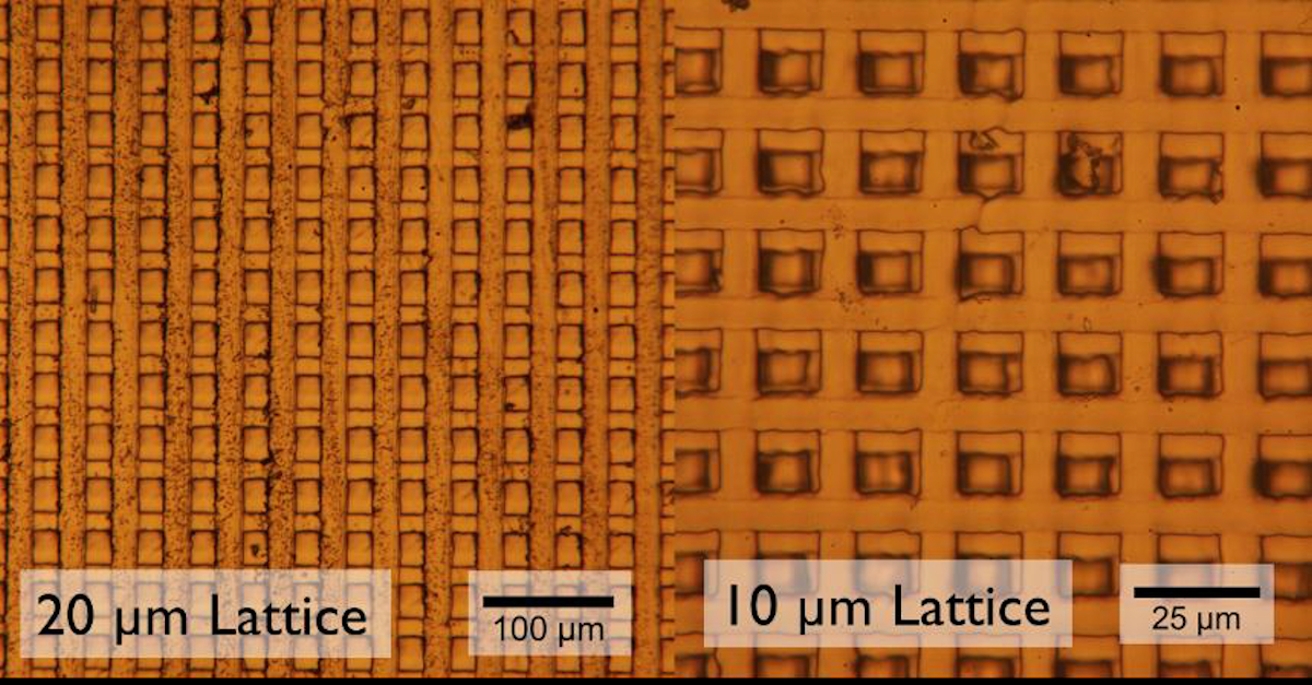

The process utilizes composite imaging where large-scale, low-resolution patterns are printed using a DLP projector. Within these low-res layers, pre-defined photomasks enable the realization of micro-features. Switching photomask patterns between layers can create three-dimensional repetitive micro-features. You can see this demonstrated in the image below.

The method can be implemented in conventional DLP 3D printers with only minor modifications, which is handy because that’s exactly what atum3D specializes in.

“We think that combining our current DLP technology with this new technology results in a game-changing platform,” said Budel.

“It brings possibilities that the market has never seen before: combining large decimetre scale printing with micron size features and all that in just a couple of hours.”

The system can print a variety of standard and also resins containing metals and other fillers such as ceramics.

Consequently it can be used to print applications ranging from microfluidic devices right through to organ scaffolds. The researchers seem keen to try the system on the latter.

“Thanks to the scalability of the technology, building a production facility that can reliably and controllably produce organ scaffolds becomes a real possibility,” he said.

They envision being able to print an entire heart scaffold in just a day, and a kidney scaffold in just a few hours, although they concede that while the printer is capable of printing such fine details, it isn’t quite ready for printing actual implantable organs just yet. This takes a lot more research, particularly from the biomedical perspective.

Other Applications

As mentioned, the system has uses in the domain of microfluidics, being capable of printing components with 200 μm channels and 20 μm restrictions. These devices could be used to contain and localize chromatographic stationary phase particles, thus opening up new possibilities in the field of 3D-printed analytical devices.

Other uses include the rapid production of mechanical metamaterials, semiconductors and porous columns for reactions and separations in chemistry. atum3D has already begun developing an application based on the technology with their first customers.