Incus GmbH, a Vienna-based company, has additively manufactured a key component for a ceremonial mace designed by Yale University graduate Jacob Eldred. The stainless steel 316L part, created using Incus’ lithography‐based metal manufacturing (LMM) technology, is a centerpiece of the mace, which symbolizes the evolution of engineering through its design.

From traditional to modern

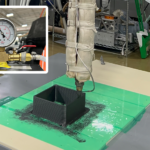

The mace, designed for Yale University’s School of Engineering, represents the progression from traditional to modern materials, shapes, and manufacturing techniques. The structure begins with a hand-carved wooden base, followed by brass and copper elements, and increasingly complex shapes made from aluminum and stainless steel using CNC and advanced 3D printing methods. Near the top of the sculpture, the additively manufactured part crafted by Incus symbolizes the future of engineering. This piece, where the trunk of the tree splits into branches, plays a crucial role in holding the structure together and showcases the capabilities of Incus’ technology.

The Incus-manufactured component features intricate internal geometries and complex curved surfaces that cannot be achieved through traditional machining or casting methods. These advanced manufacturing techniques allow for the creation of visually captivating shapes, leaving viewers intrigued by the possibilities of modern metalworking.

Jacob Eldred, the artist and engineer behind the design, was inspired by the natural flowing shapes found in historical craftsmanship, such as the elaborate forms created from wood, ivory, and silver during earlier centuries. He noted how the limitations of early machine tools during the Industrial Revolution led to simpler, flat designs, but emphasized that today’s advanced automation and 3D printing have brought back the ability to produce intricate curves, overhangs, and lattices.

“With advanced automation and 3D printing, we can create elaborate curves, overhangs, and lattices. By producing these complex shapes with the Hammer Lab35 printer in my sculpture, I’m continuing the tradition of sculptors pushing technological boundaries,” Eldred said. He expressed excitement about how engineers might start thinking in more complex forms as they adopt these advanced manufacturing techniques.

Incus GmbH’s contribution to the Yale University mace not only demonstrates the company’s expertise in advanced manufacturing but also serves as a symbol of how engineering and art can merge to push the limits of design. The mace, with its combination of traditional craftsmanship and modern technology, reflects the ongoing evolution in the field of engineering and the expanding possibilities offered by additive manufacturing.

Source: metal-am.com