Powercore, a Kickstarter project, aims to bring the power of electric discharge machining (EDM) to the home DIY-ers, making it possible to create aluminum parts as easily and cheaply as printing something in plastic on an FDM machine.

EDM works by using electric arcs to erode metal from a workpiece, which allows for precision parts to be produced quickly. Compared to traditional subtractive manufacturing, EDM is much cleaner than CNC cutting, as there are no chips flying around, making it an attractive option for the home lab.

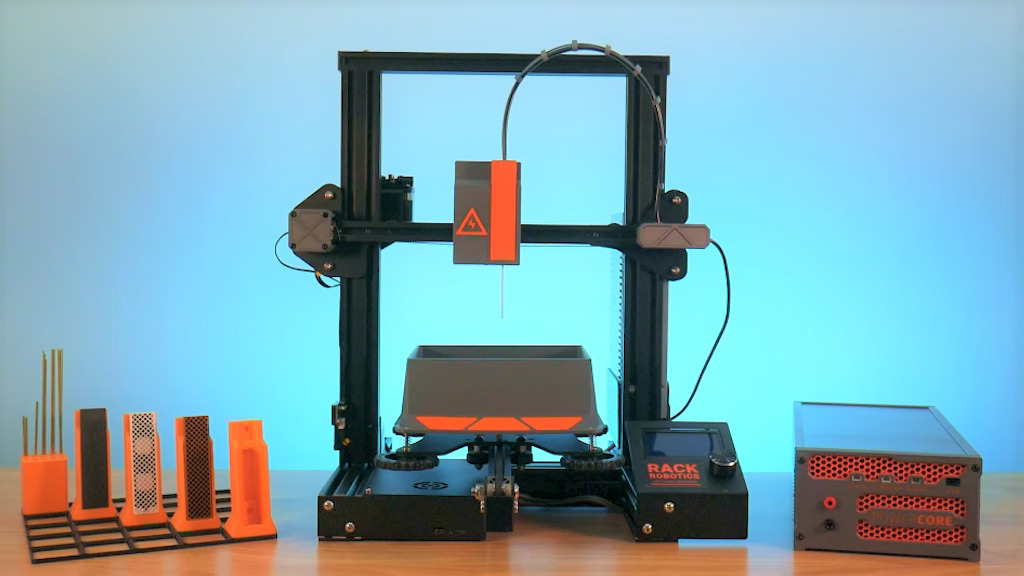

Powercore is designed to replace the extruder of a standard 3D printer and consists almost entirely of parts printed on the same machine, with an interesting approach to keeping costs down by creating power resistors from PCBs. The project has evolved from a project on Hackaday and is poised to make a difference in desktop manufacturing.

Feast your eyes on the Powercore at work in the video below. Looks good, right? I would buy one, and they’re not sponsoring us to say that.

With a sub-$200 investment, users can start making accurate metal parts without chips flying around, and without dropping a ton of cash on a desktop plasma cutter.

Overall, Powercore is an exciting development for the desktop manufacturing revolution, and could change the game for DIY makers and creators. So throw that $200 joke of a CNC router you bought from AliExpress out the window, and head on over to the project Kickstarter page if you want to experience some low-cost EDM action.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.