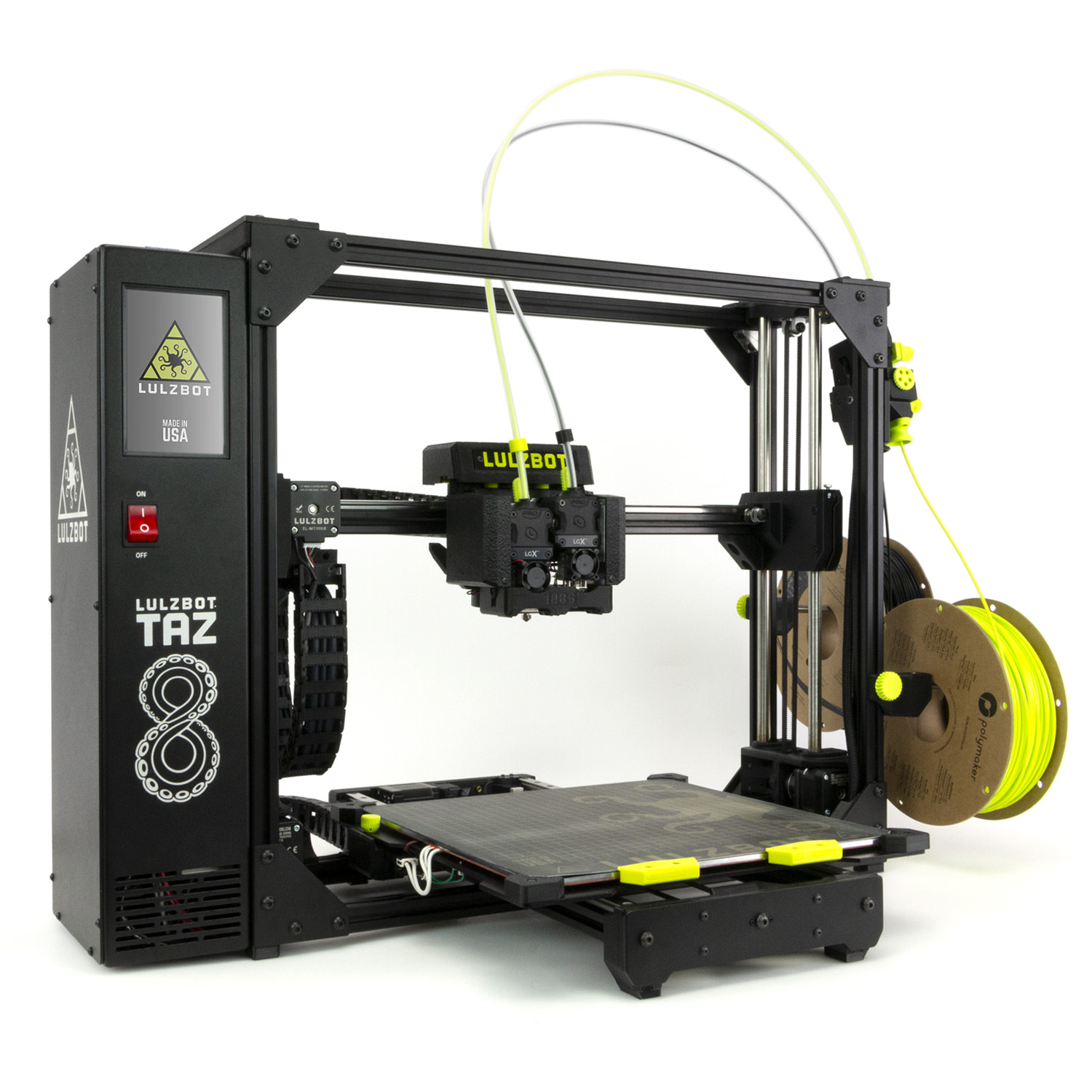

LulzBot is officially launching the TAZ 8 today, a desktop 3D printer built for industrial reliability and precision. Designed and manufactured in Fargo, North Dakota, the TAZ 8 supports professionals across manufacturing and engineering with features that emphasize repeatability, speed, and ease of use.

Precision Engineering and Mechanical Stability

At the core of the TAZ 8’s engineering is a robust mechanical system that includes dual independent Z-axis movement with 5.18:1 gearboxes and 12mm rods, ensuring consistent X-axis tramming. Linear rails on both X and Y axes provide smooth motion and enable faster, high-quality printing. Combined with improved backlash compensation, the system helps reduce defects caused by mechanical play and enhances overall print precision.

Advanced Bed Technology and Cooling

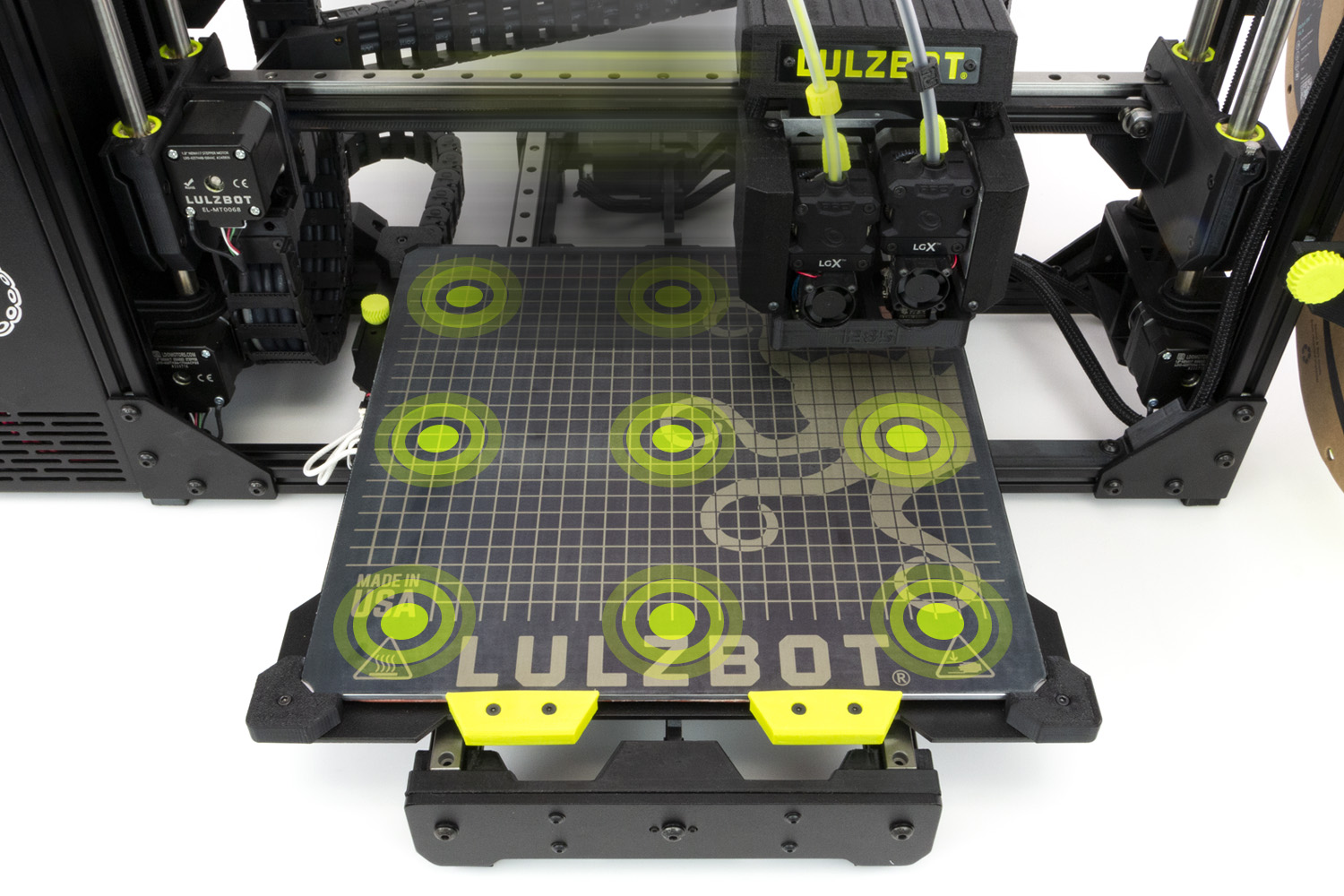

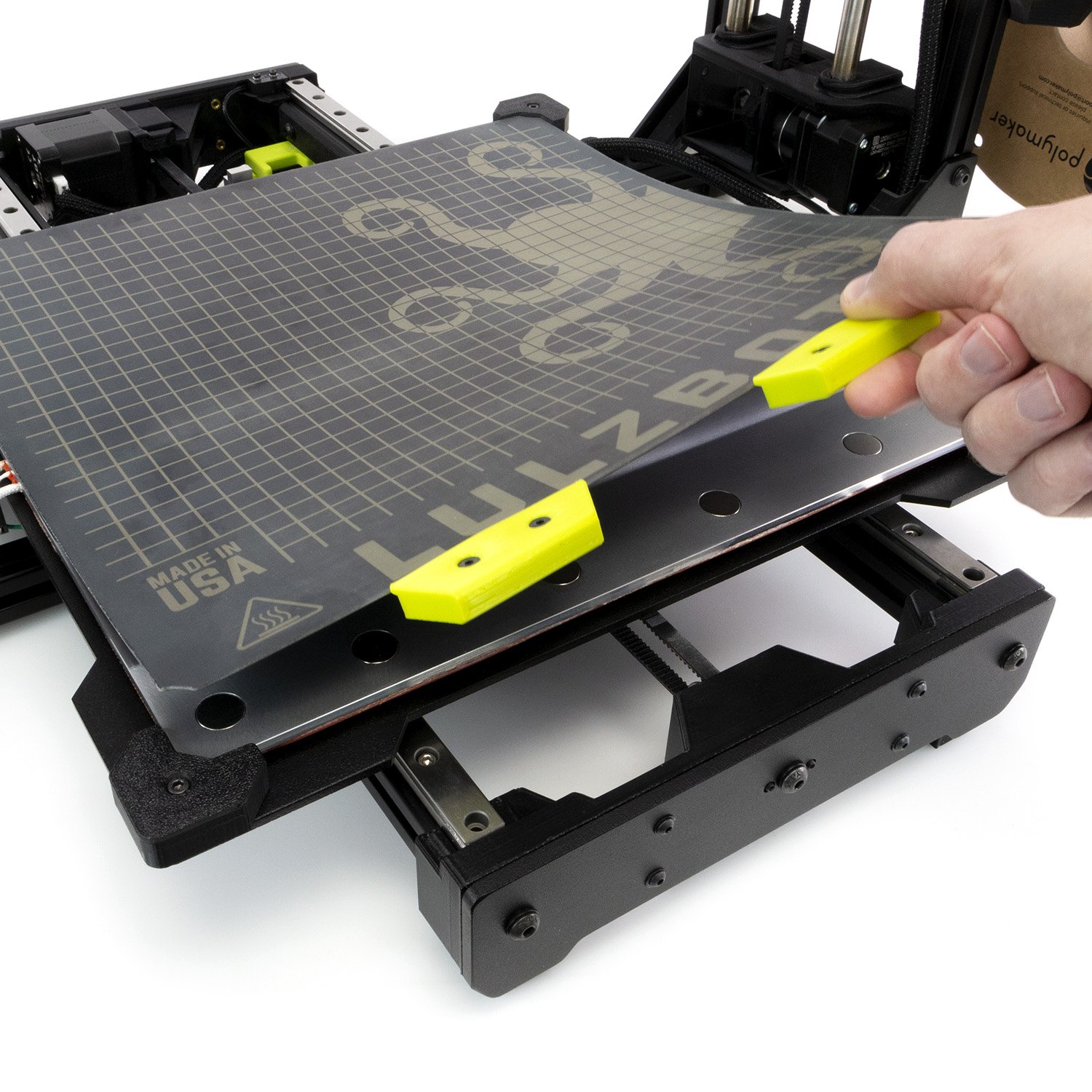

The printer uses an automatic 16-point mesh bed leveling system powered by a BLTouch probe, along with automatic X-axis tramming and Z-offset calibration. A new active bed cooling system reduces downtime between prints by quickly lowering bed temperatures, improving throughput and maintaining material integrity. The print bed is magnetic and allows for easy swapping of surface materials to accommodate different filaments.

Updated Electronics and Firmware

Powered by a 32-bit Archim 2.2b board with Trinamic TMC2130 drivers and an Xpand board, the TAZ 8 benefits from additional stepper channels and reduced signal interference. Sensorless homing has been replaced with mechanical limit switches for better reliability. The system supports Cura LE (LulzBot Edition) slicer software and is compatible with Windows, macOS, and Linux. Connectivity options include USB serial and SD card support, with an 8GB card included for standalone printing.

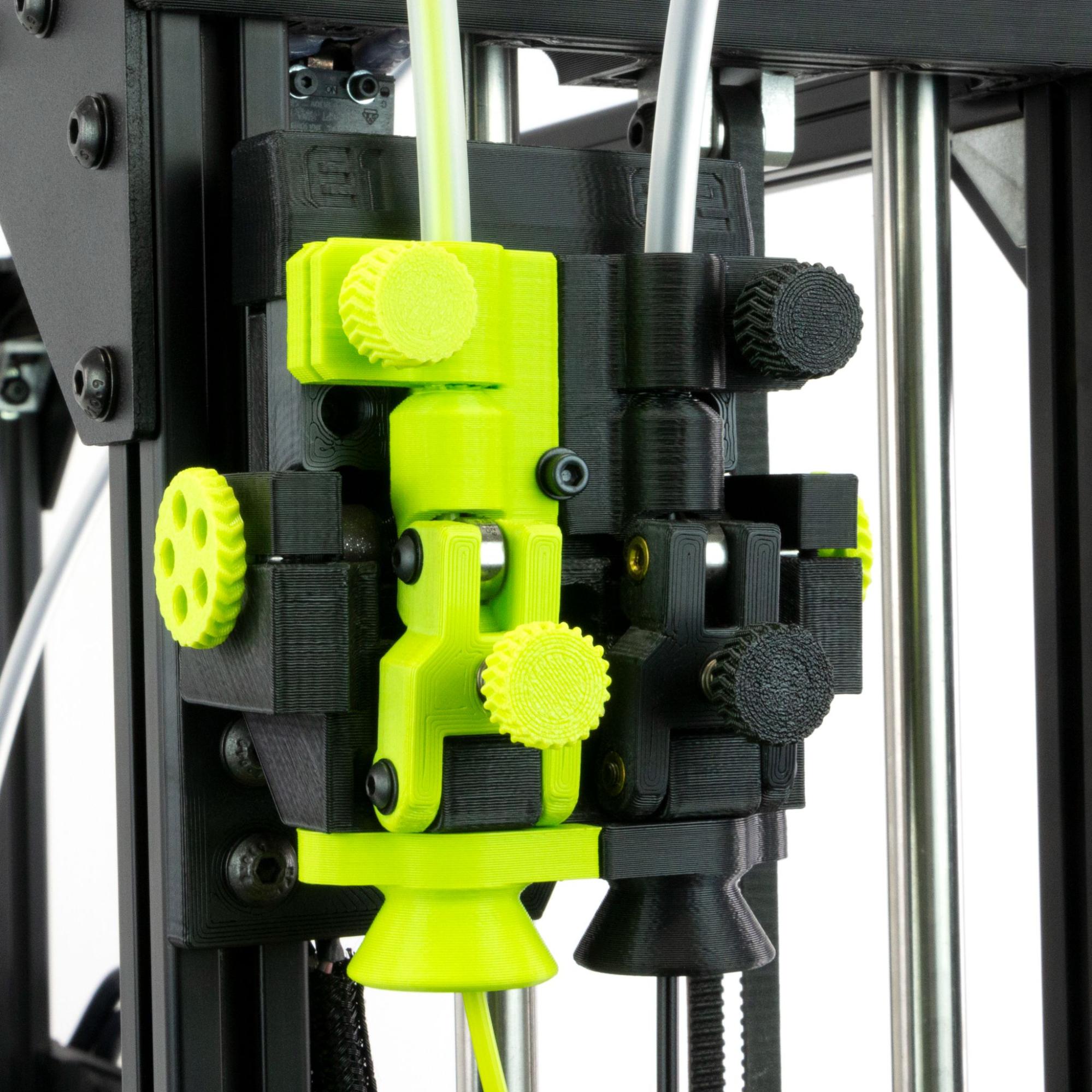

Tool Head and Material Versatility

Users can select from Galaxy Series tool heads in both single and dual extrusion configurations. These tool heads are equipped with powerful heaters and dual-drive, direct-drive extruders capable of handling a broad range of materials. The TAZ 8 supports 2.85mm or 1.75mm filament (depending on the tool head) and can print with PLA, TPU, ABS, PETg, PVA, PVB, nylon, PC, and others requiring temperatures up to 290°C.

User-Centric Features

Operator-focused features include a glove-friendly resistive touchscreen with updated navigation, tool-free tool head changes using magnetic caps and thumbscrews, and filament sensors that detect runout and jams. Stainless steel spool holders are compatible with both cardboard and plastic spools of various sizes.

Technical Specifications and Included Items

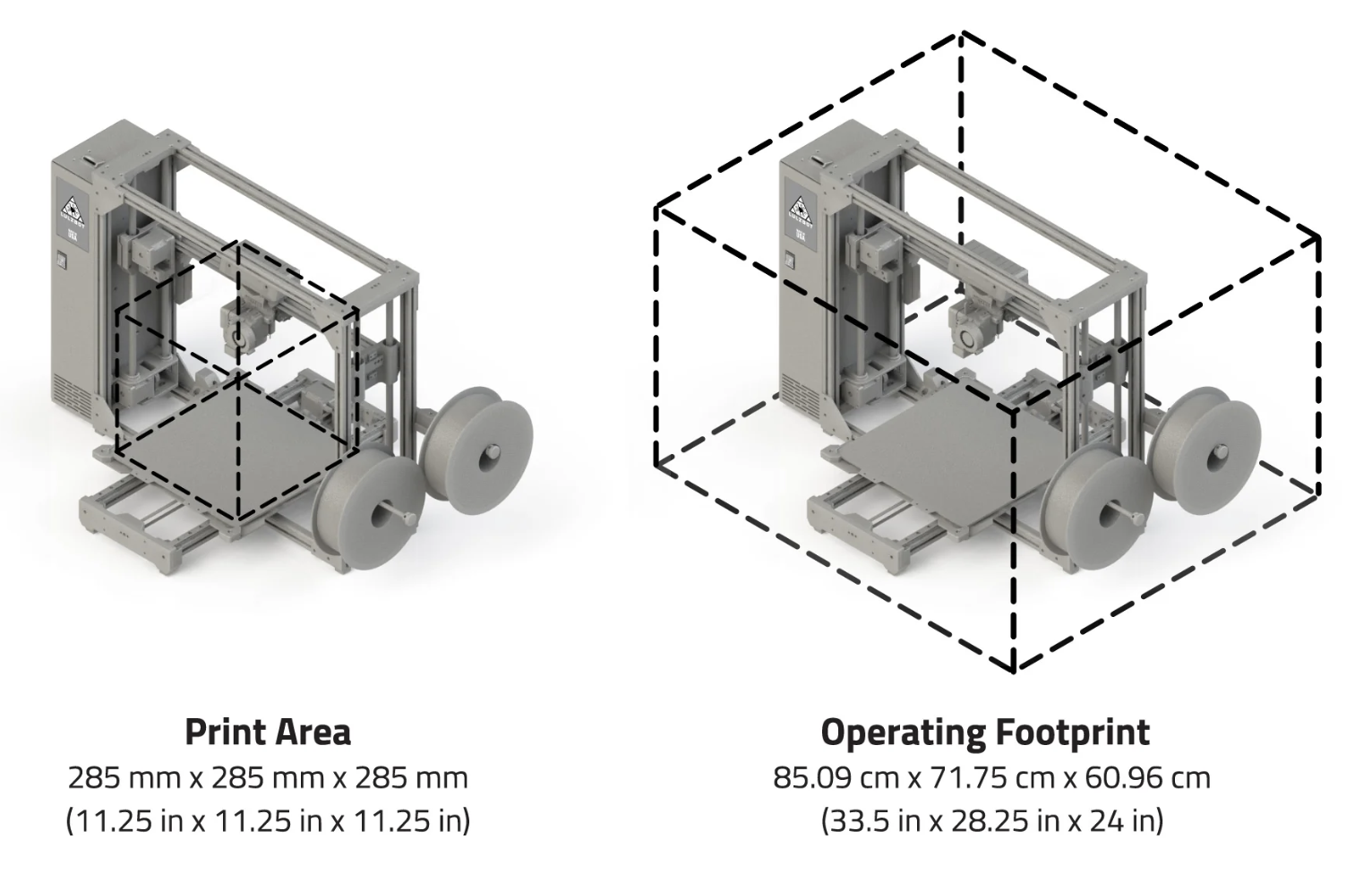

The build volume of the TAZ 8 is 285 x 285 x 285 mm, with a layer height range of 0.1mm to 0.4mm. Positional resolution is 0.01mm on the X and Y axes and 0.0019mm on the Z axis, with travel speeds of up to 500 mm/s. The heated bed reaches up to 110°C, and the 500W Mean Well power supply supports input voltages from 100VAC to 240VAC.

Each unit is assembled and supported in the U.S., backed by a one-year standard warranty with extended options available. In addition to the printer, buyers receive a premium tool kit, 1kg each of LulzBot Green and Black PLA (tool head dependent), an SD card, and access to the LulzLessons curriculum and Cura LE software downloads.

Industrial-Ready and Available Now

With its upgraded motion system, electrical components, tool head flexibility, and strong customer support, the LulzBot TAZ 8 offers a compelling solution for professionals seeking a durable and adaptable 3D printer for prototyping, production aids, and tooling.

More information is available at LulzBot.com/taz8.