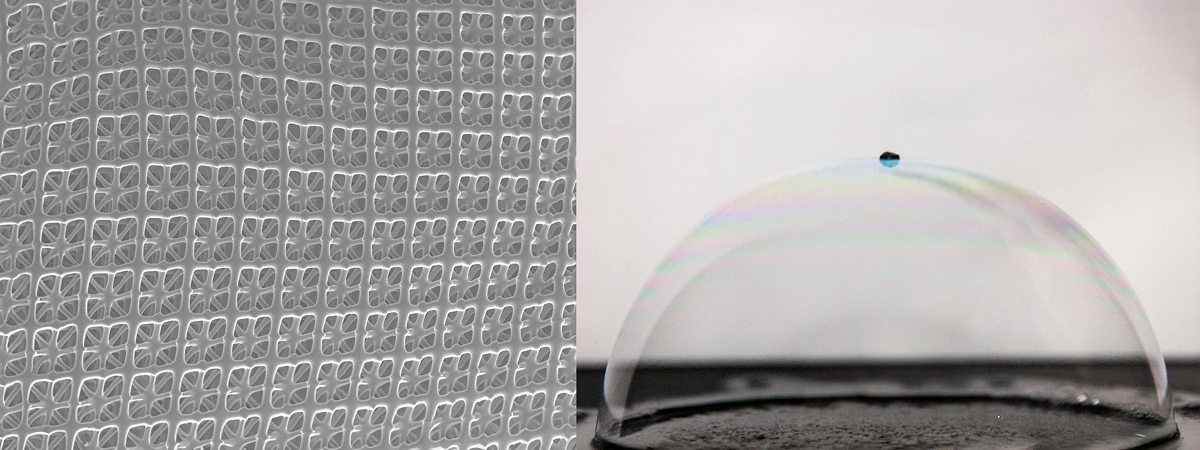

University of Toronto researchers have developed new nano-architected materials that combine the strength of carbon steel with the low density of Styrofoam. The team used machine learning to design optimized carbon nanolattices, which are complex 3D structures made of tiny building blocks measuring a few hundred nanometers in size. The research was published in Advanced Materials.

The new materials were created through a collaboration between the University of Toronto and the Korea Advanced Institute of Science & Technology (KAIST). The team employed a multi-objective Bayesian optimization algorithm to predict optimal geometries for improving strength-to-weight ratios. Using a two-photon polymerization 3D printer, researchers produced prototypes for experimental validation.

The optimized nanolattices demonstrated significant performance improvements over existing designs. The materials achieved a stress resistance of 2.03 megapascals for every cubic metre per kilogram of density, which is approximately five times higher than titanium. These results were achieved using a relatively small dataset of 400 points, compared to the typical requirement of 20,000 or more data points.

The potential applications span multiple industries, particularly aerospace. According to the researchers, replacing titanium components in aircraft with these materials could result in fuel savings of 80 liters per year for each kilogram of material substituted. This reduction in fuel consumption could help decrease the carbon footprint of air travel.

The research team, led by Professor Tobin Filleter, is now focusing on scaling up the material designs to enable cost-effective macroscale components. They continue to explore new designs that maintain high strength and stiffness while further reducing density. The project brought together expertise from multiple institutions, including MIT, Rice University, and the Karlsruhe Institute of Technology.

Source: news.engineering.utoronto.ca