A maker operating under the brand “Printed Pulse” has developed SignalForm, a 3D printed portable speaker system designed to be repairable and customizable. The project aims to create an alternative to closed commercial audio systems by using additive manufacturing techniques and standard electronic components.

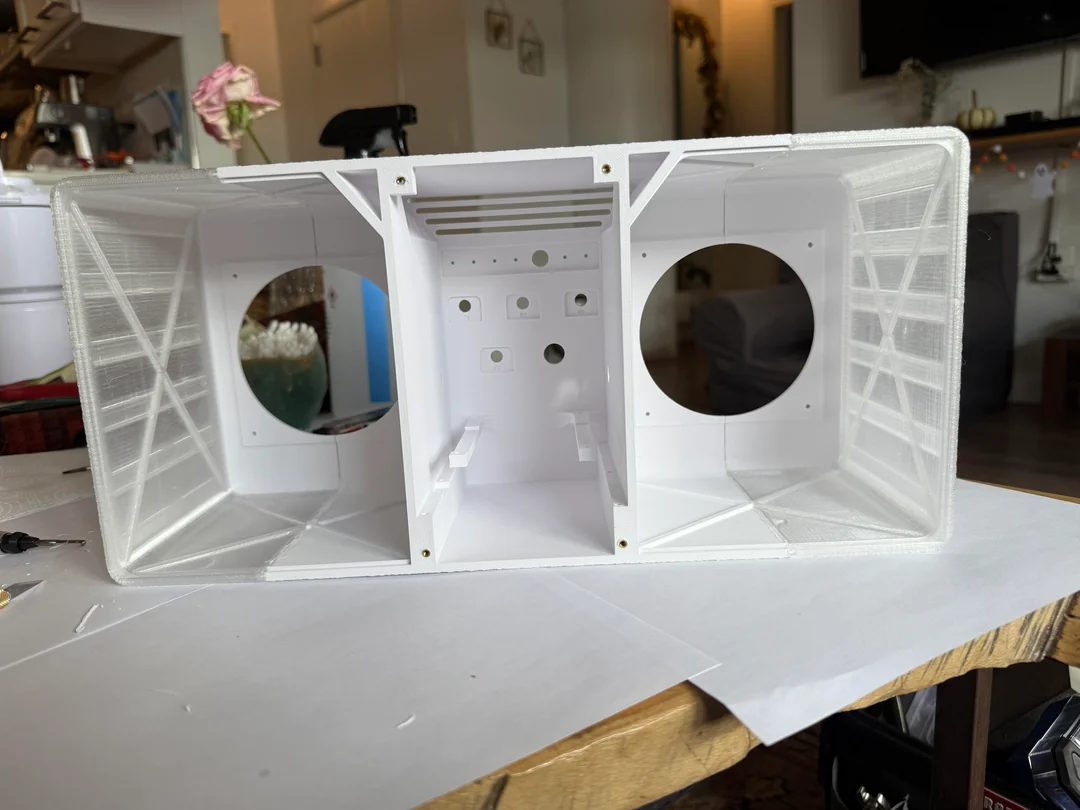

The speaker system features a body printed in Bambu PETG HF material with translucent PETG panels and TPU isolation mounts for vibration control. It incorporates dual Dayton Audio DMA105-8 full-range drivers paired with ND105 passive radiators, powered by a Dayton Audio KABD-250 amplifier and a 5×18650 battery board providing 21V of power. The enclosure consists of sealed chambers of approximately 2.8 liters each, with a central electronics bay that includes cooling channels.

The audio system reportedly achieves a frequency response of 65 Hz to 20 kHz with output measuring around 95 dB at 2 meters. Controls include physical bass, mid, and treble adjustments, Bluetooth 5.0 with aptX HD support, a 3.5mm auxiliary input, and USB-C charging. The design uses no digital signal processing, relying instead on acoustic design and driver pairing.

The project has been launched on MakerWorld as a community-driven build, with plans to release STL files, bill of materials, and assembly instructions upon completion. The modular split-shell design allows printing on smaller beds and uses tongue-and-groove joints for assembly. The creator is seeking community feedback on damping materials, print settings, and strategies for minimizing resonance in 3D printed audio enclosures.

Source: reddit.com