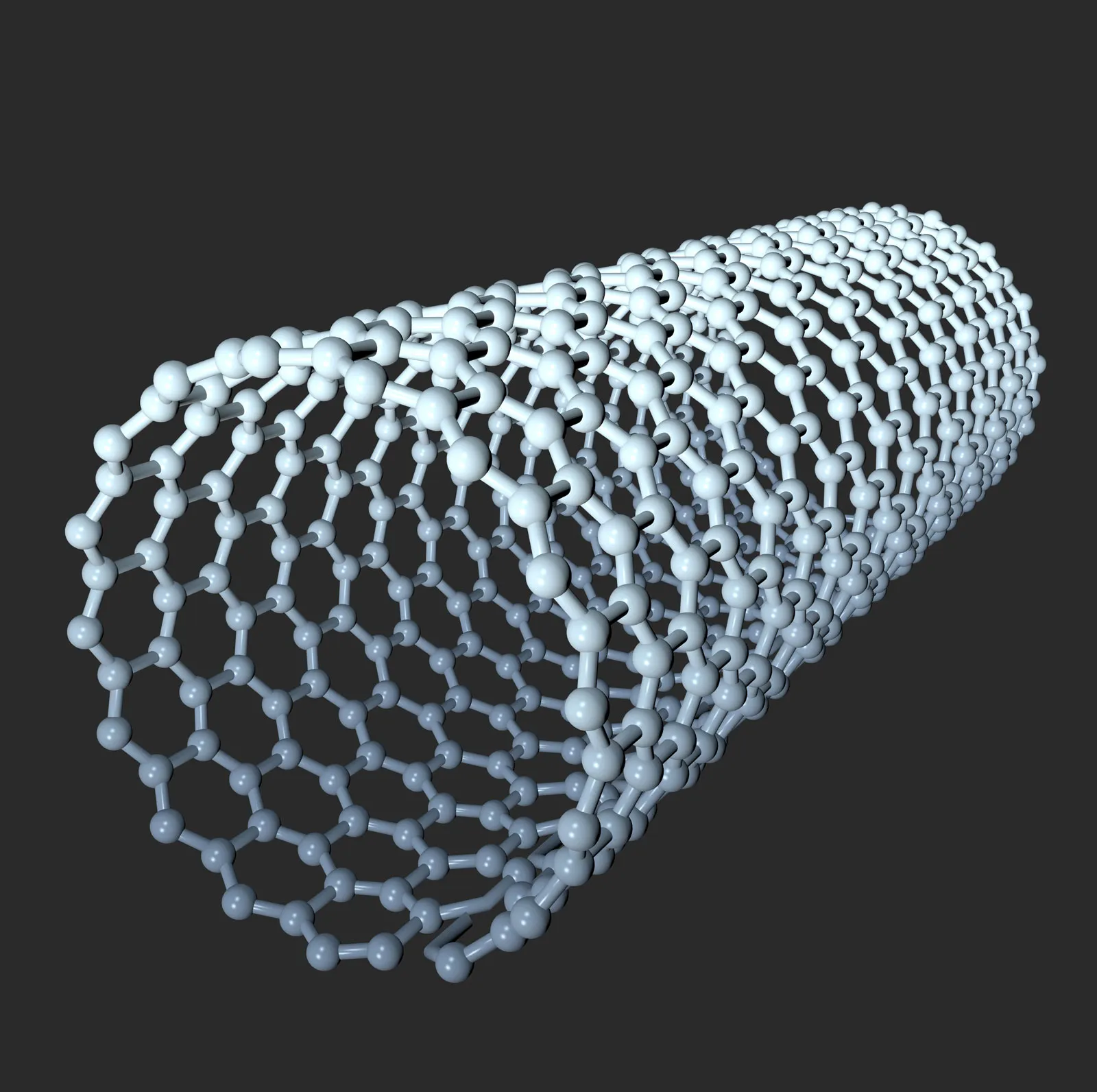

Mechnano, a 3D printing startup based in Mesa, Arizona, has trademarked its proprietary CNT dispersion process called D’Func. The process solves the problem of clumped and roped carbon nanotubes (CNTs) in additive manufacturing materials, leading to increased electrical and mechanical performance in printed parts.

Dirty tube dispersions are known to be mechanically inferior to their base formulas, resulting in broken parts or processes that need to be shut down as replacements are put in place. On the other hand, D’Func dispersions improve the mechanical properties of AM materials, making them more functionalized and discrete.

“Mechnano’s D’Func dispersions are by nature clean and are the answer for today’s increasingly stringent requirements for true static dissipation by AM fabricated parts from resins, powders, pellets and beyond,” said Bryce Keeler, president at Mechnano.

“D’Func provides nano-uniform ESD protection throughout the part, regardless of the process, which is why it is becoming the industry standard for AM providers who want consistent, reliable, nano-uniform ESD properties.”

D’Func is represented by over 130 issued patents, making it a highly protected and innovative process. The dirty tubes can leave insulative pockets that reject charges trying to dissipate to the ground, clump into ropes that create lightning rod effects that destroy electronics, and leave residual metals from the CNT creation process that cause additional electrical and mechanical part failures in electrostatic discharge (ESD) applications.

Mechnano’s CNT dispersion process solves these problems by creating discrete, dispersed, and functionalized CNT dispersions that improve the mechanical and electrical properties of printed parts, making them more durable and reliable.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.