The possible healthcare advantages of 3D printing technology are well-known. You’ve probably read at least one story about how additive manufacturing technology is used in medicine. Dental implants and prosthetics are among many applications of 3D printing in this field.

Hyperelastic Bone

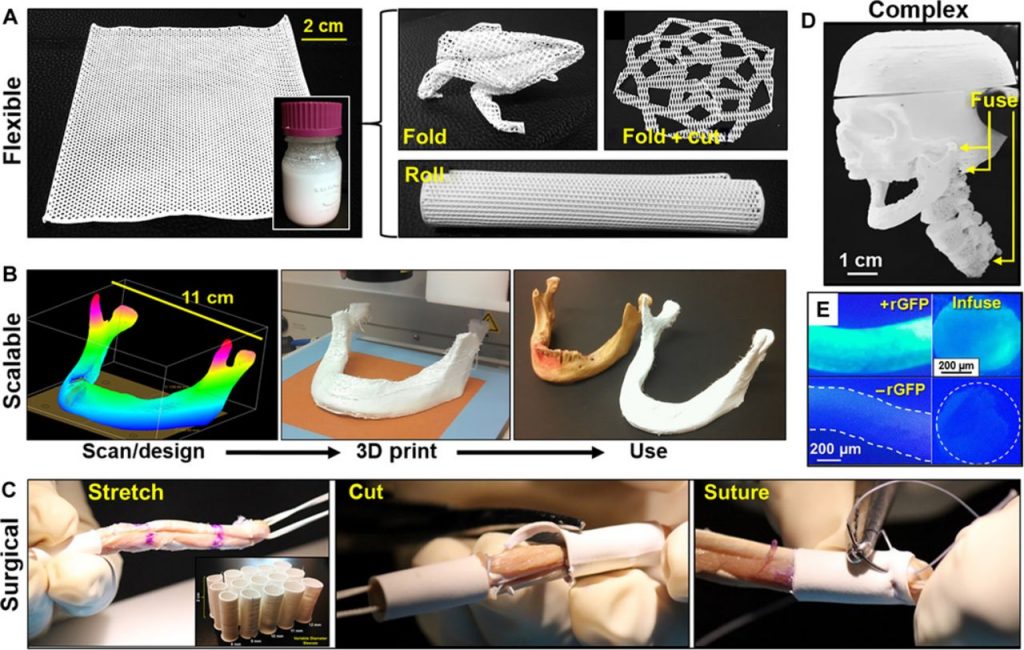

In a huge leap for medical science and 3D printing, researchers at an Illinois university recently revealed a new composite bone material they call hyperelastic bone. 3D printers quickly customize the material, depending on the specific needs of each patient. This potentially allows surgeons to implant it on demand to help heal damaged bones in the body.

Furthermore, the composite bioengineered material also seems to promote the growth of bones in the vicinity of the structure. This could mean quicker healing times for a wide range of skeletal injuries.

Implant Rejection

A huge factor in the hype around this material is that it gives promising results in terms of implant rejection, which is a huge issue with current technology. Modern bone grafts utilize materials such as collagen and ceramics. The body often rejects these implants, resulting in a number of frustrating side effects. These side effects range from pain to infection to implant displacement.

The lab rats that scientists tested the new hyperelastic material on didn’t show any sign at all of rejecting the implants.

Composition

Hyperelastic bone is made from a ceramic powder form of hydroxyapatite, a mineral found in bones, and a polymer known as polycaprolactone. This polymer is popular for its biomedical applications chiefly because of its malleability. The material is porous, meaning that an organism’s blood vessels have the ability to quickly infiltrate it. The quick infiltration by the body allows it to incorporate the implant without triggering an immune response.

Strength

Obviously, it’s important not to get too carried away seeing as hyperelastic bone technology is in its infancy. But it does offer a viable way to improve current implants. The key point is that this biomaterial has the advantage minimal chances of implant rejection. It is also extremely strong. The team of scientists 3D printed a section of human femur, and the material supported loads up to 150 pounds before buckling.

It’s too early to make any estimation about the potential cost of this technology. The benefits are clear. Human trials have an important role to play in verifying its efficacy, though.

If hyperelastic bone fulfills its promise and the people in charge manage to keep cost to a minimum, this represents a significant medical breakthrough. Don’t be surprised to hear more about hyperelastic bone over the coming two or three years.