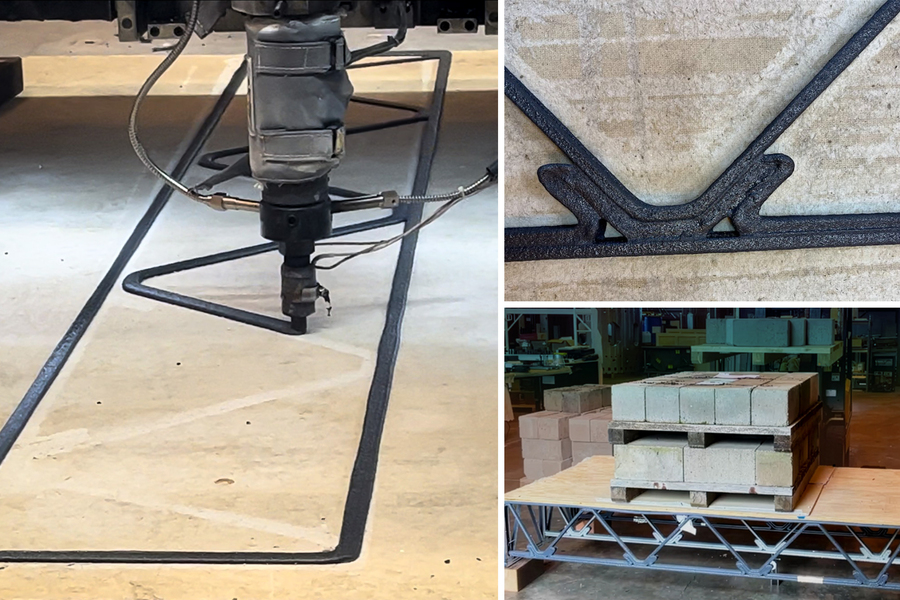

MIT researchers have developed a method to 3D print construction-grade structural elements from recycled plastic, creating floor trusses that meet U.S. building standards. The team published their findings in the Solid FreeForm Fabrication Symposium Proceedings, detailing how they printed four 8-foot floor trusses that successfully supported over 4,000 pounds of weight. Each truss weighs approximately 13 pounds and can be printed in under 13 minutes using an industrial-scale 3D printer.

The printed trusses exceeded load-bearing requirements set by the U.S. Department of Housing and Urban Development while offering weight advantages over traditional wood alternatives. The researchers used pellets made from recycled PET polymers and glass fibers as their printing material. The trusses were configured into a conventional plywood-topped floor frame for testing purposes.

The MIT HAUS group, established in 2019 within the Laboratory for Manufacturing and Productivity, focuses on producing homes from recycled polymer products using large-scale additive manufacturing. “We’ve estimated that the world needs about 1 billion new homes by 2050. If we try to make that many homes using wood, we would need to clear-cut the equivalent of the Amazon rainforest three times over,” says AJ Perez, a lecturer in the MIT School of Engineering and research scientist in the MIT Office of Innovation.

The researchers aim to eventually use “dirty” plastic materials that require minimal preprocessing, such as used bottles with liquid residue. Currently, they are working on printing additional structural elements to create a complete frame for a modest-sized home. The team envisions a future system where shipping containers equipped with shredding and printing technology could be deployed near high-plastic-waste areas to produce lightweight building components that can be transported by pickup truck.

Source: news.mit.edu