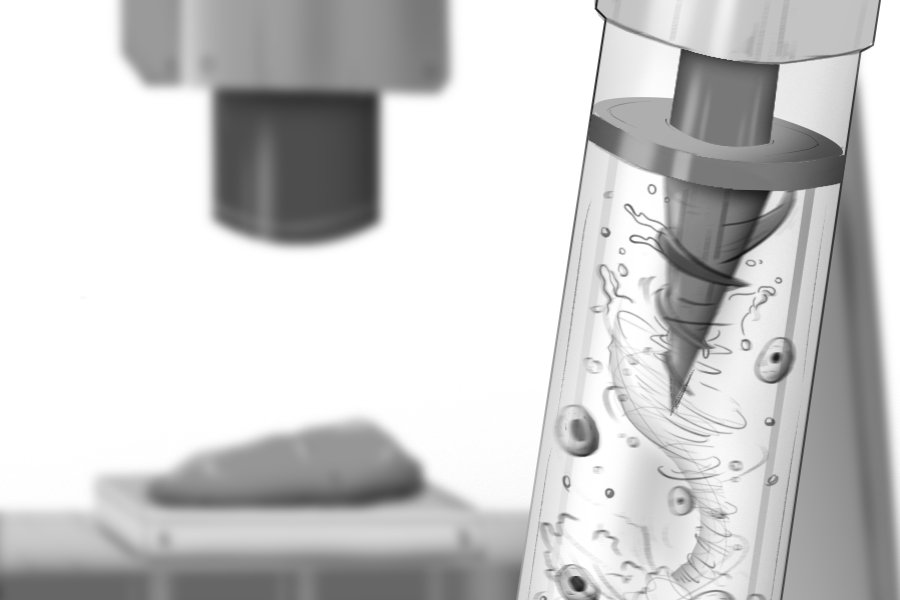

MIT researchers have developed a magnetic mixing system called MagMix to address a persistent challenge in 3D bioprinting where cells settle to the bottom of printer syringes during long printing sessions. The system consists of a small magnetic propeller that fits inside bioprinter syringes and a permanent magnet attached to a motor that controls the propeller’s movement. Published February 2 in the journal Device, the study demonstrates how this approach maintains uniform cell distribution throughout the printing process.

“This cell settling, which becomes worse during the long print sessions required to print large tissues, leads to clogged nozzles, uneven cell distribution, and inconsistencies between printed tissues,” explains Ritu Raman, the Eugene Bell Career Development Professor of Tissue Engineering and assistant professor of mechanical engineering at MIT. Current solutions like manual stirring or passive mixers cannot maintain uniformity once printing begins, according to the researchers.

Testing showed that MagMix prevented cell settling for more than 45 minutes of continuous printing across multiple bioink types while reducing clogging and maintaining high cell viability. The team used computer simulations to optimize the propeller design and speed, then validated the results experimentally. As a proof-of-concept, researchers demonstrated that the system could print cells that developed into muscle tissues over several days.

The compact device can be mounted on standard 3D bioprinters without changing bioink formulations or interfering with normal printer operations. Lead author Ferdows Afghah, a postdoc in mechanical engineering at MIT, noted that “precise control over the bioink’s physical and biological properties is essential for recreating the structure and function of native tissues.” The researchers believe improved tissue printing could support disease modeling, drug testing, and eventually regenerative medicine applications.

The work was supported by MIT’s Safety, Health, and Environmental Discovery Lab (SHED), which focuses on translating biofabrication innovations from laboratory demonstrations to scalable applications. “MagMix is a strong example of how the right combination of technical infrastructure and interdisciplinary support can move biofabrication technologies toward scalable, real-world impact,” says Tolga Durak, SHED’s founding director.

Source: news.mit.edu